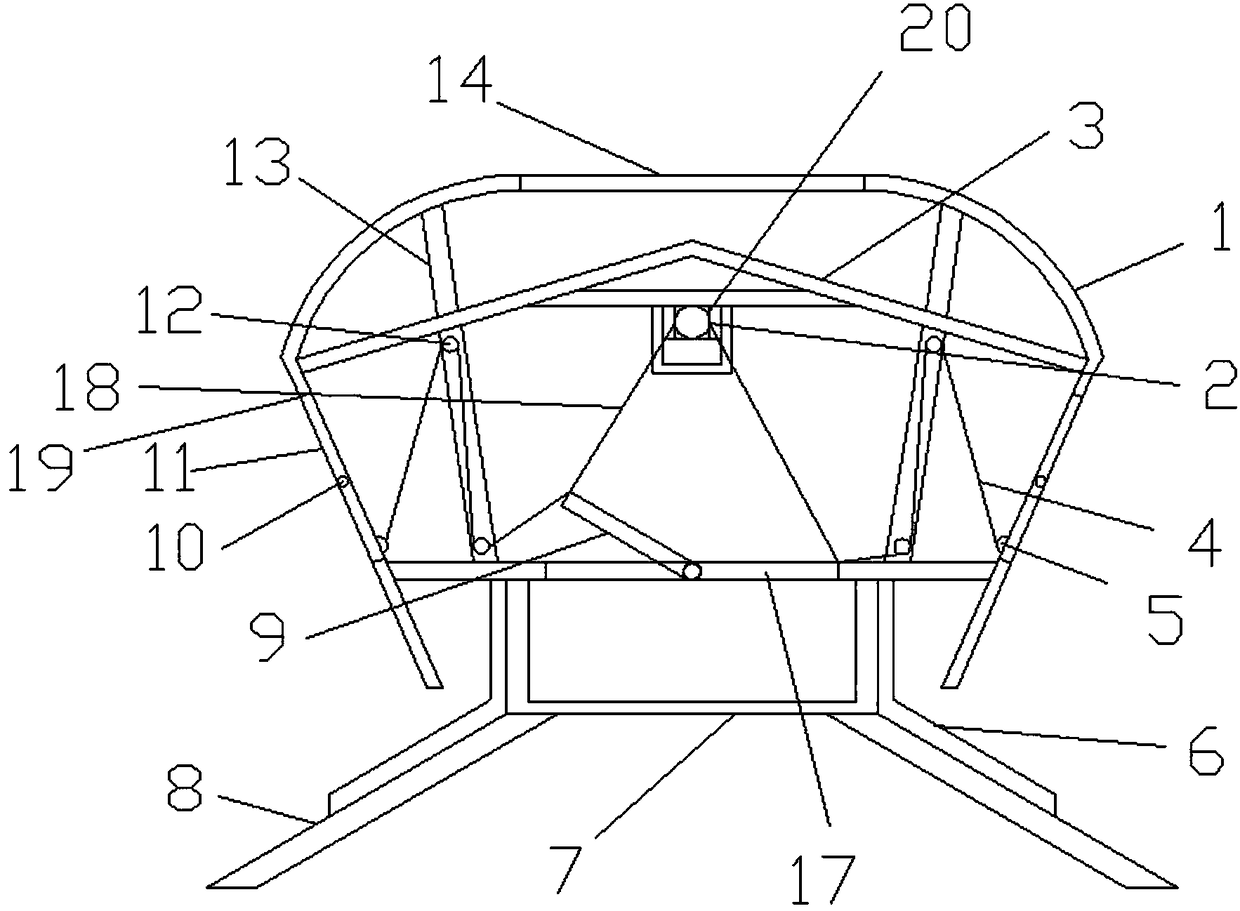

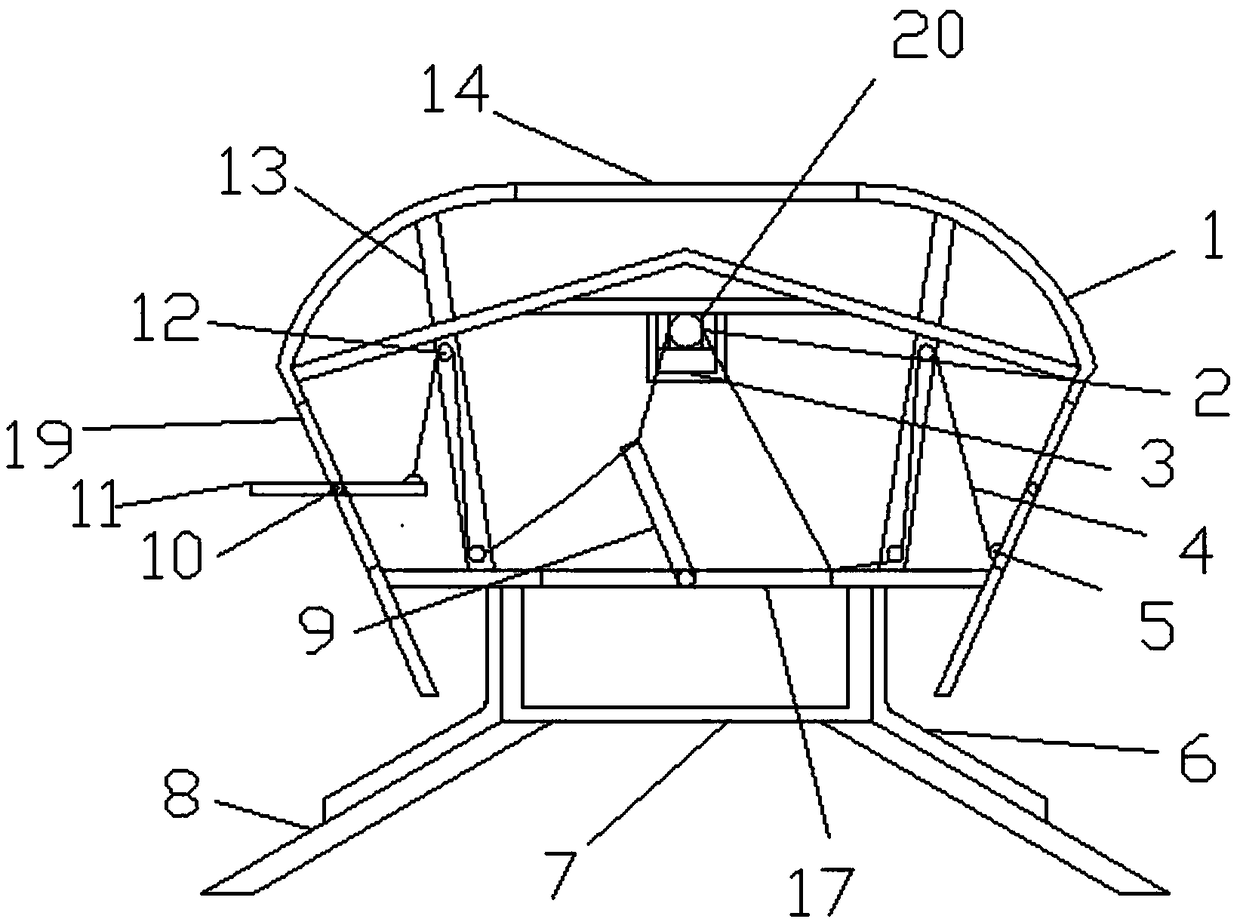

Electric opening and closing type clerestory of steel structure factory building

A technology of opening and closing, steel structure, which is applied in the direction of building components, building structures, power control mechanisms, etc., and can solve problems such as the inability to adjust the size of the vent, damage to equipment, and turbulent air flow in the factory building.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

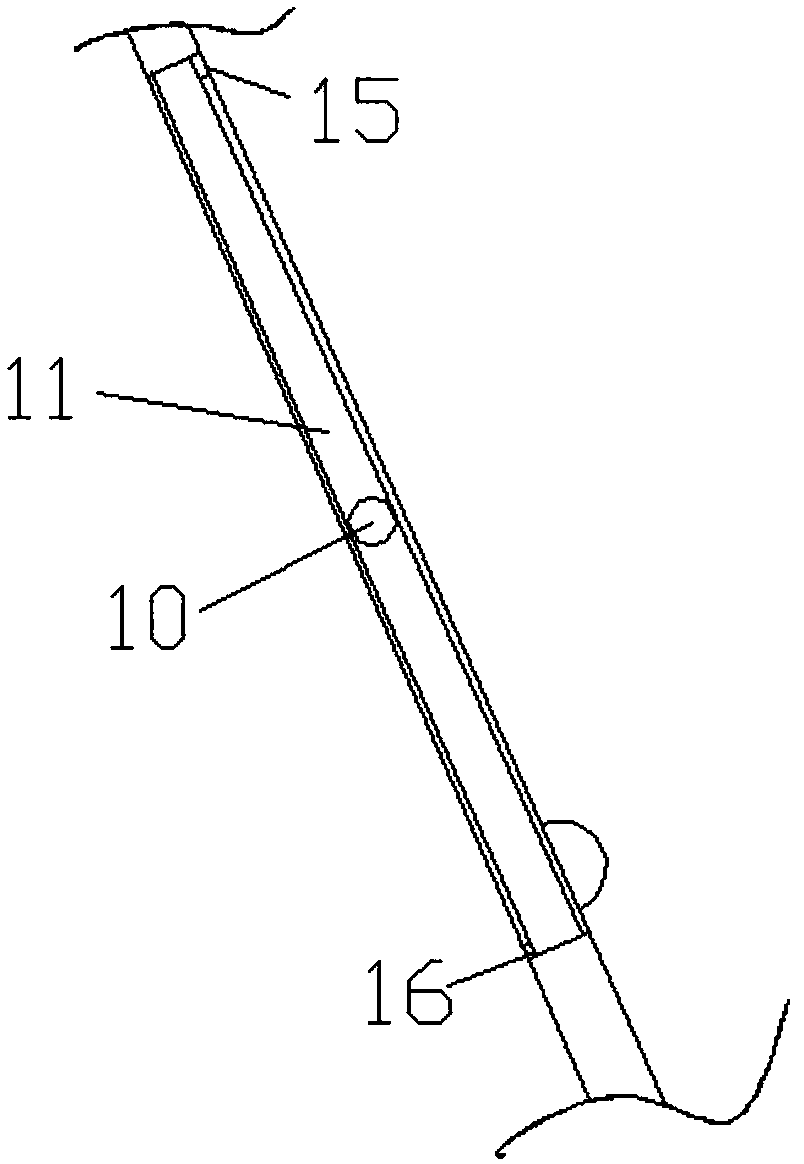

[0024] Embodiment: when the air in the factory building is dirty, and the ventilation requirements in the factory building are higher, the motor 20 drives the reel 2 to rotate, and the reel 2 drives the traction rope 18 to lift the movable air plate 9 on the upper side of the vent 17 to the greatest extent. At the same time, the movable wind panel 9 drives the second traction rope 4 to turn up the door panel 11 and open it. At this time, a large amount of dirty air in the workshop is discharged from the ventilation port 17 under the movable air panel 9 on one side to the frame body 19, which can be selected according to the wind direction of the day. Open one side of the movable wind panel 9, when encountering strong wind and heavy rainfall, the reel 2 is reversed, and the traction rope 18 is driven to lower the movable wind panel 9 on one side to close the vent 17, and the door body 11 is not protected from the second traction rope. 4 when the traction force returns to its ori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com