Supercritical CO2 fluid foaming machine

A supercritical and foamer technology, applied in the field of foaming, can solve the problems that researchers are difficult to obtain the expected experimental results, the air tightness of the device is weakened, and the support frame is difficult to balance, so as to achieve reasonable distribution and fixed stability of the temperature measuring device The effect of improving, accurate and effective measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The following are specific embodiments of the invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

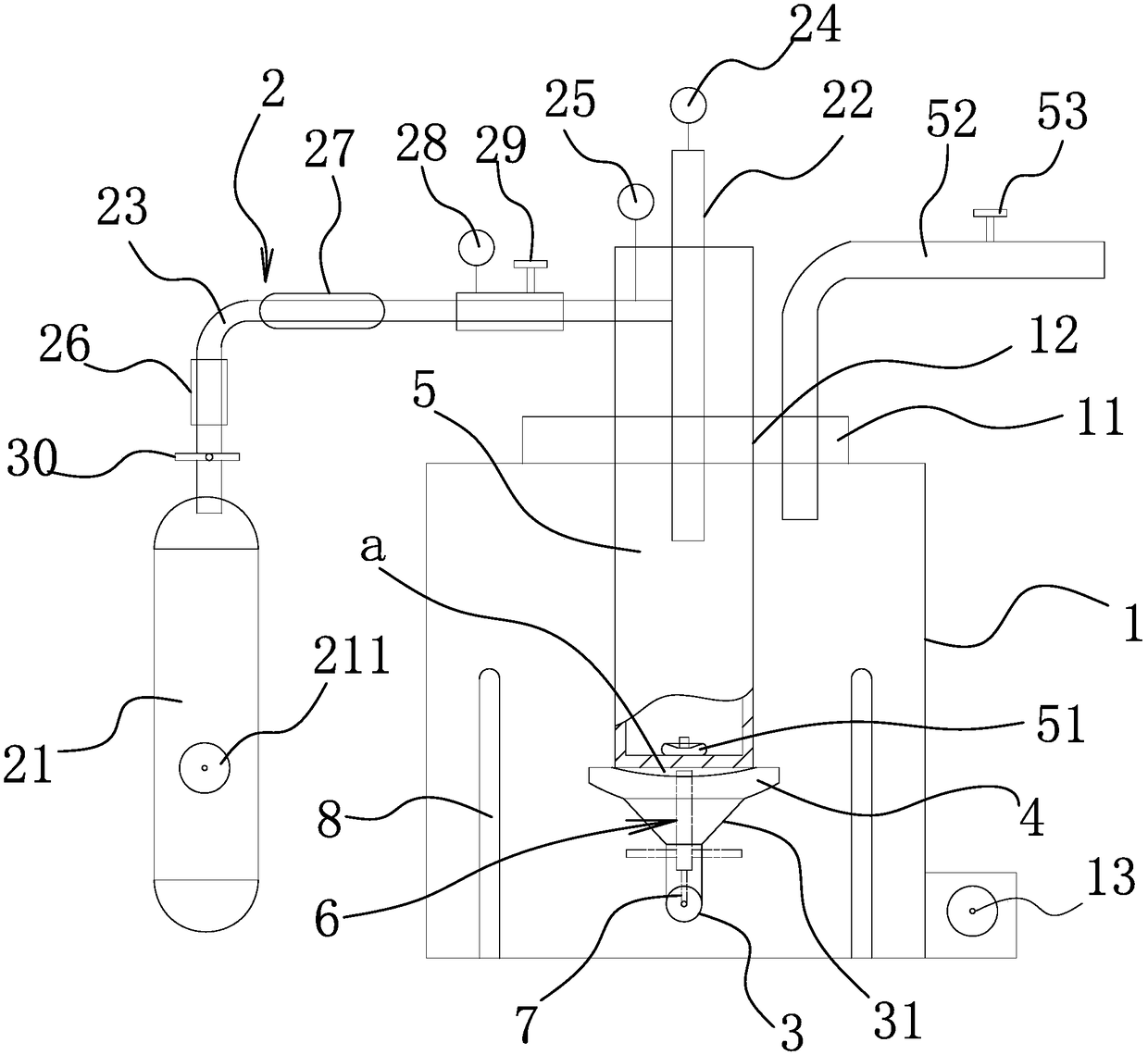

[0066] Such as figure 1 As shown, the supercritical CO 2 The fluid foamer includes a sealed cylinder 1, a pressurizing device 2, and a heating medium stored in the sealed cylinder 1, and the heating medium is oil.

[0067] An insulation layer is arranged on the inner wall of the sealed cylinder.

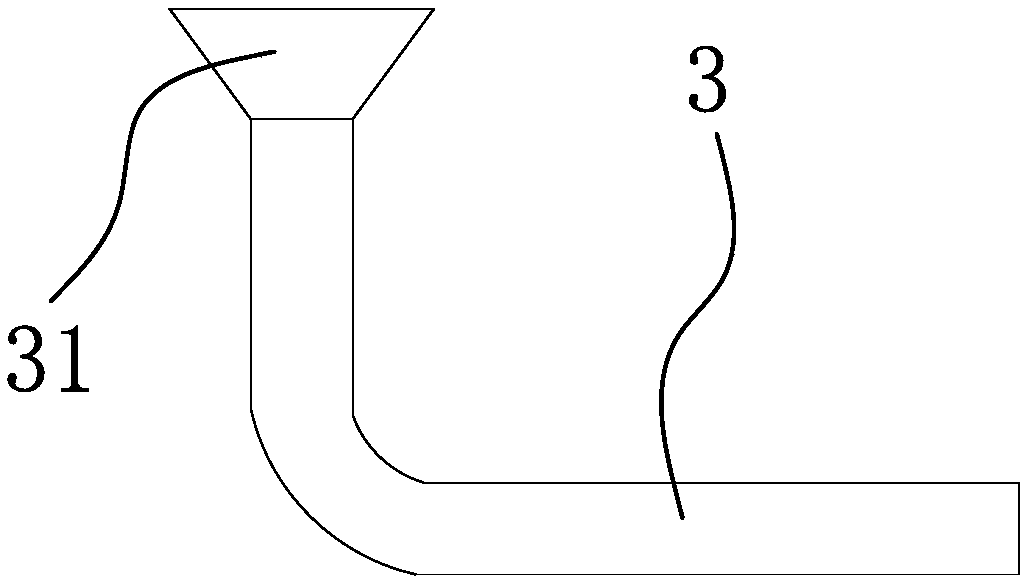

[0068] Such as Figure 1-2 As shown, a cantilever support tube 3 is connected to the inner wall of the sealed cylinder body 1, and the cantilever support tube 3 is in an L-shaped structure. The cantilever support tube 3 includes a horizontal section and a vertical section connected with the horizontal section. The segment axis coincides with the axis of the sealed cylinder 1.

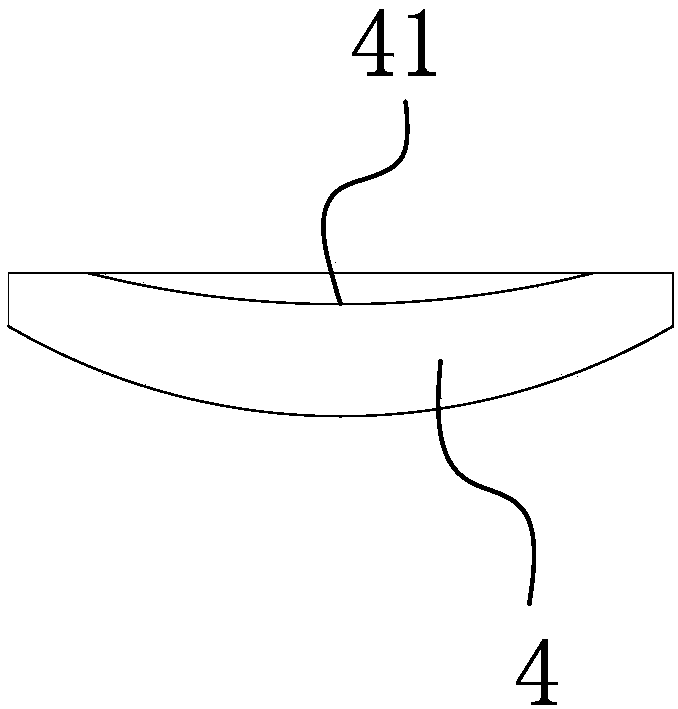

[0069] One end of the horizontal section away from the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com