Sewing machine and variable-needle-pitch mechanism thereof

A sewing machine and variable technology, applied in sewing machine components, sewing machine control devices, cloth feeding mechanisms, etc., can solve the problems of complex structure and unstable transmission, and achieve the effects of simple structure, improved stability and reduced vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

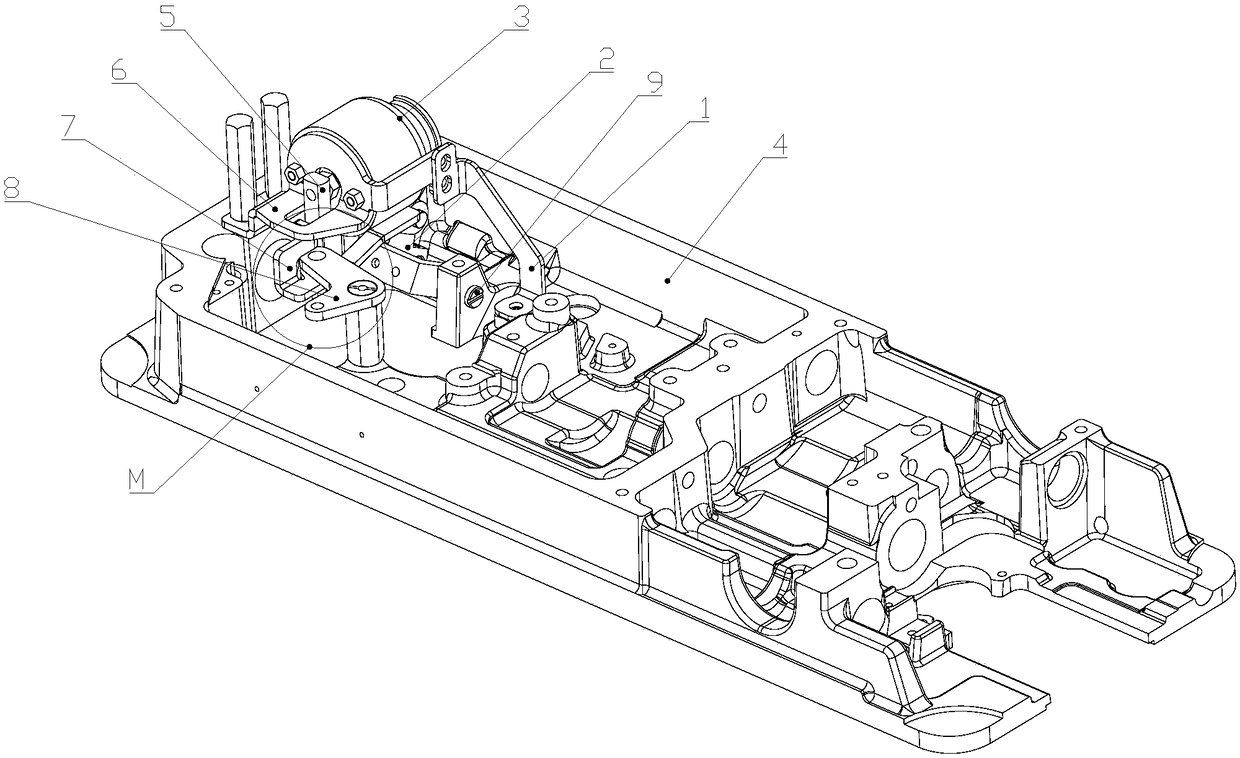

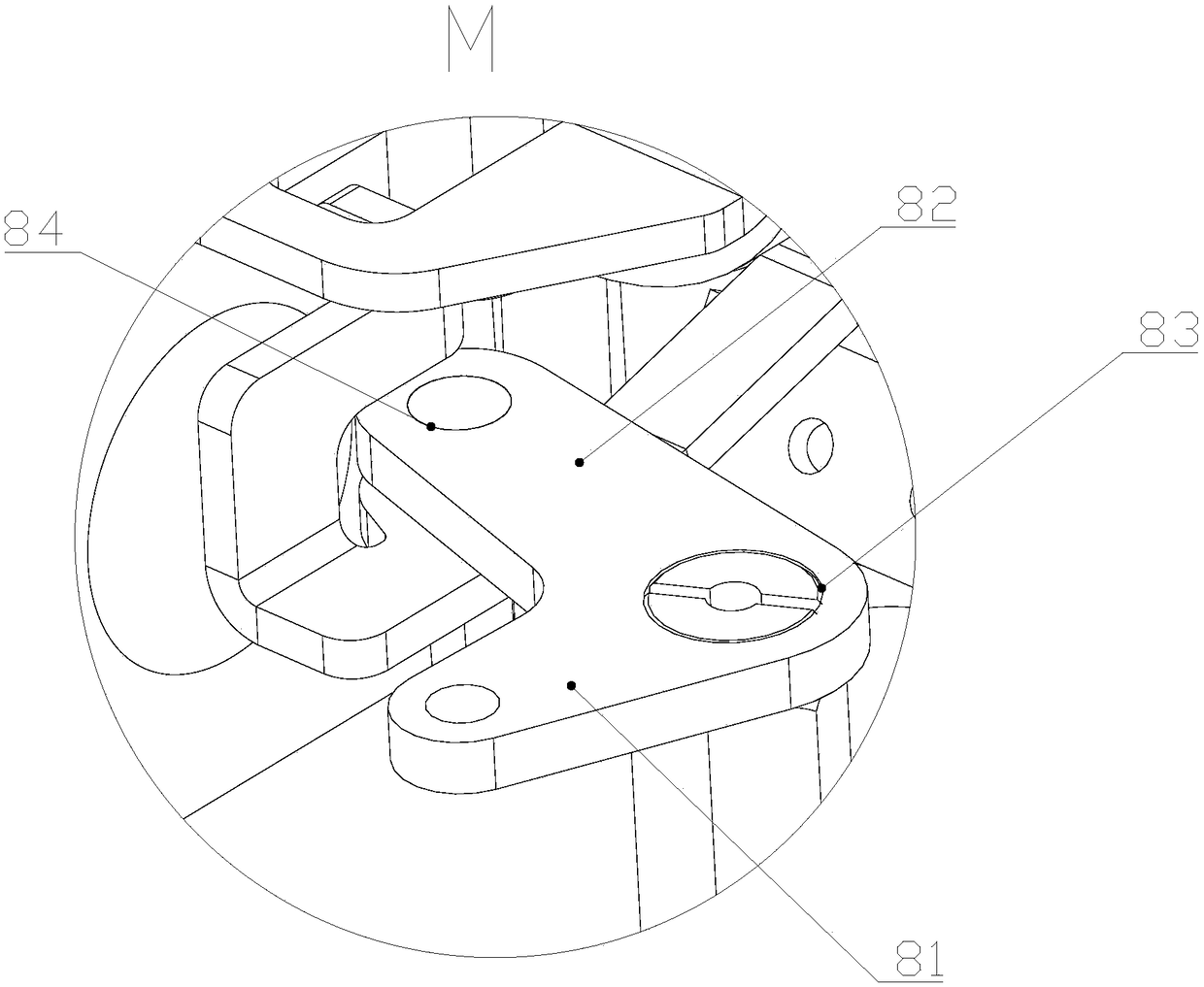

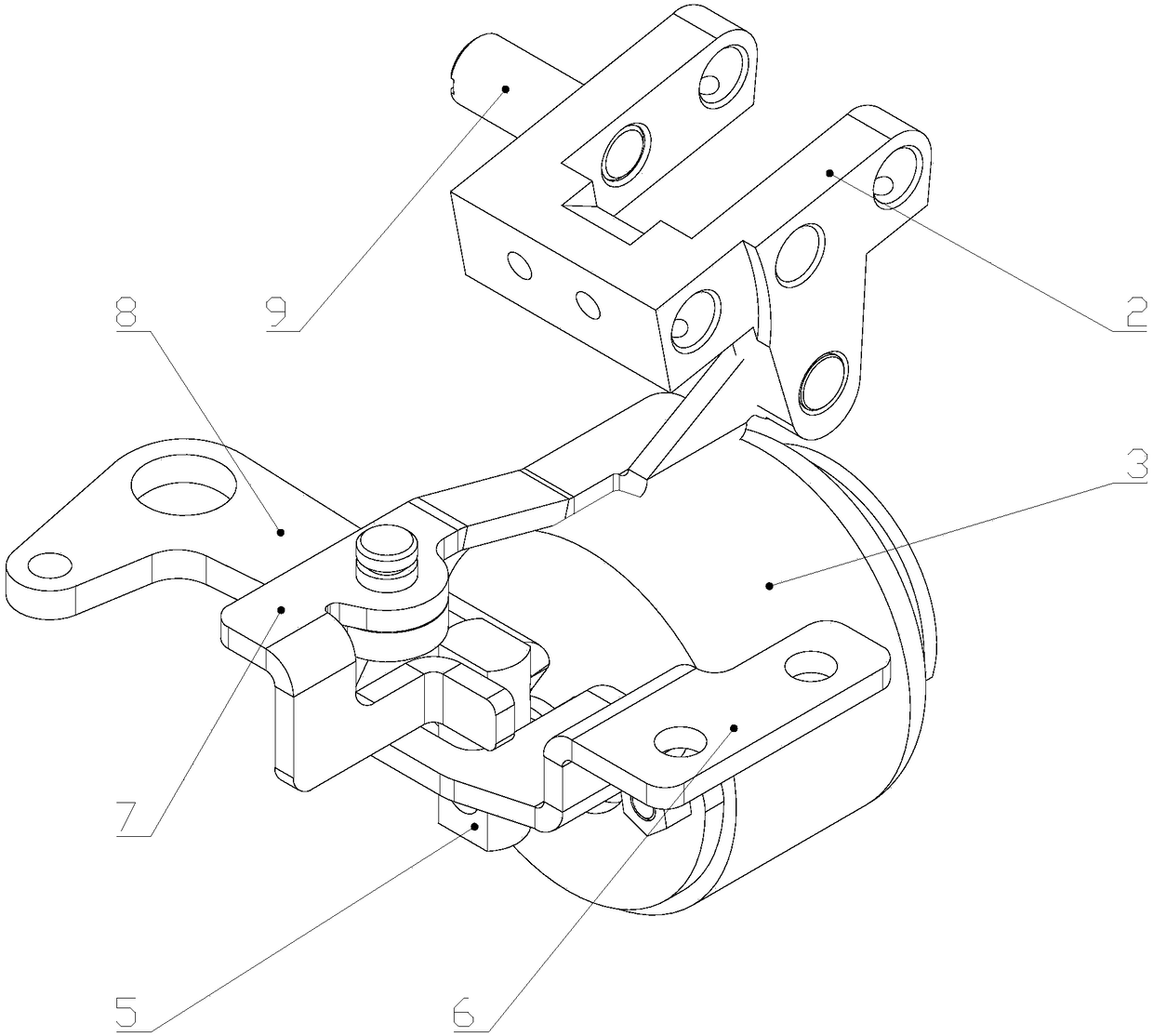

[0025] Variable stitch length mechanism of sewing machine, such as Figure 1 to Figure 7 As shown, it includes a driver 3, an automatic reverse feed connecting rod 7, and a swing plate seat 2. The driver 3 is provided with a movable part 5 fixedly connected to the driver 3. One end of the automatic reverse feed connecting rod 7 is connected with the movable part 5, and the automatic reverse feed The other end of the feeding connecting rod 7 is hinged with the swing plate base 2, and the other end of the automatic reverse feeding connecting rod 7 rotates relative to the swing plate base 2, and the driver 3 drives the automatic reverse feeding connecting rod 7 to move through the movable part 5. The driver 3 is a linear drive device such as an electromagnet or a cylinder. The action of the driver 3 drives the movable part 5 to move, and the movable part 5 drives the automatic reverse feeding rod 7 to move a certain distance, and at the same time, the automatic reverse feeding rod...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap