Hydrating curing concrete floor

A technology of concrete and wet curing, which is applied to floors, building components, buildings, etc., and can solve problems such as difficult realization of floors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

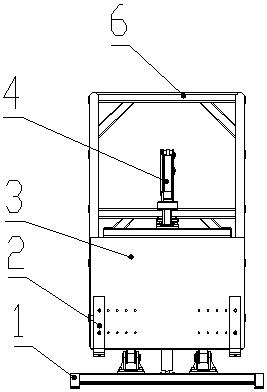

[0006] The present invention will be further described below in conjunction with the accompanying drawings.

[0007] like figure 1 Shown is a moisture-retaining concrete floor. The floor includes a main floor and an auxiliary floor. The main floor and the auxiliary floor are made of steel skeleton and concrete pouring. There is an opening on one side of the main floor. Cuboid-sized storage chamber, the volume of the storage chamber is slightly larger than that of the auxiliary floor, four parallel guide rails are arranged at the right angle formed by the length and width of the storage chamber, the length of the guide rails is consistent with the width of the storage chamber, the lower part of the main floor It is equipped with a lifting and tightening device. The lifting and tightening device includes a pressure plate and a pressure plate. Both ends of the pressure plate and the pressure plate are provided with threaded holes, and a strong force is provided between the pressu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap