Three-consecutive-arc design method for pipe-type culvert section

A design method and culvert technology, applied in the direction of design optimization/simulation, calculation, special data processing application, etc., can solve the problems of standardization, systematic defects, scale, poor industrialization effect, waste of construction materials, etc., to reduce the The types of components and formwork, the effect of realizing large-scale and intensive manufacturing, and flexibly adjusting the cross-sectional shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

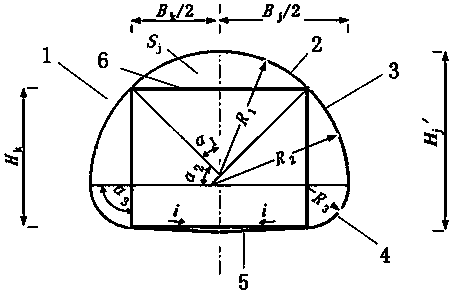

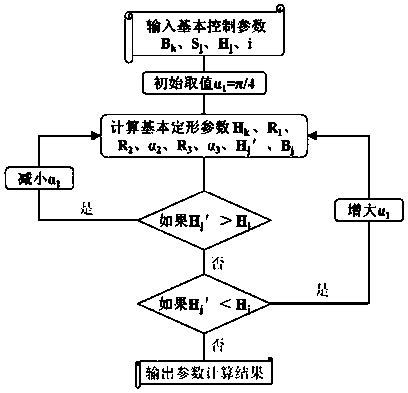

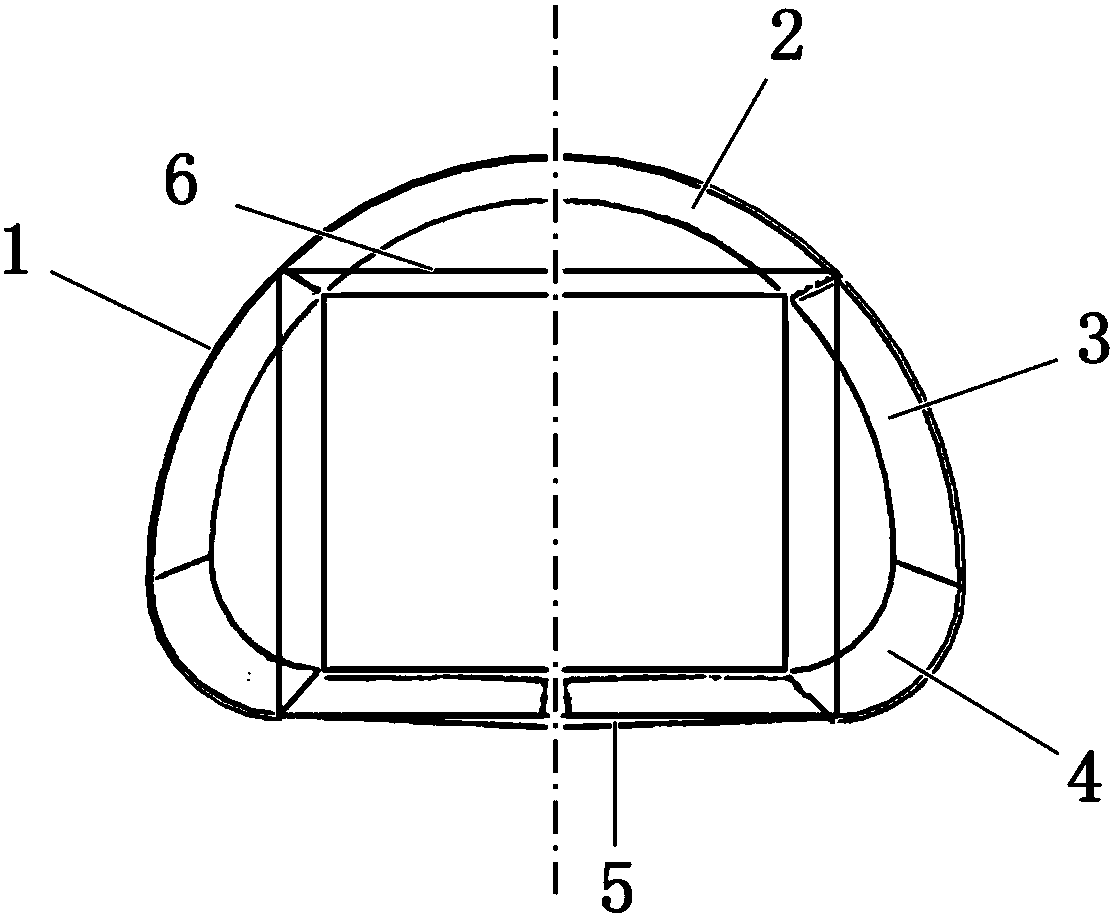

[0041] The invention provides a design method of three consecutive arcs of a tubular culvert, the three consecutive arcs are the top arc, the upper side arc and the lower side arc which are continuous and tangent on the inner contour line of the culvert section. The design of the present invention refers to The calculation of the geometric parameters of the contour line of the culvert section includes the following steps:

[0042] (1) Establish the datum for the design of the inner contour line of the culvert cross-section, and unify it into a reference rectangle inscribed in the inner contour line of the channel cross-section;

[0043] (2) Determine the basic control parameter A and the basic shaping parameter U for the design of the inner contour line of the culvert section. The basic control parameter A for the design of the inner contour line of the culvert cross-section is a known parameter, including the inscribed reference rectangle width B of the inner contour line of t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap