Improved control of remote demolition robot

A technology for dismantling robots and remote controls. It is applied to mechanical control devices, control mechanisms with multiple controlled components, and manual control mechanisms. It can solve problems such as time-consuming, unsteady and irregular dismantling of robots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

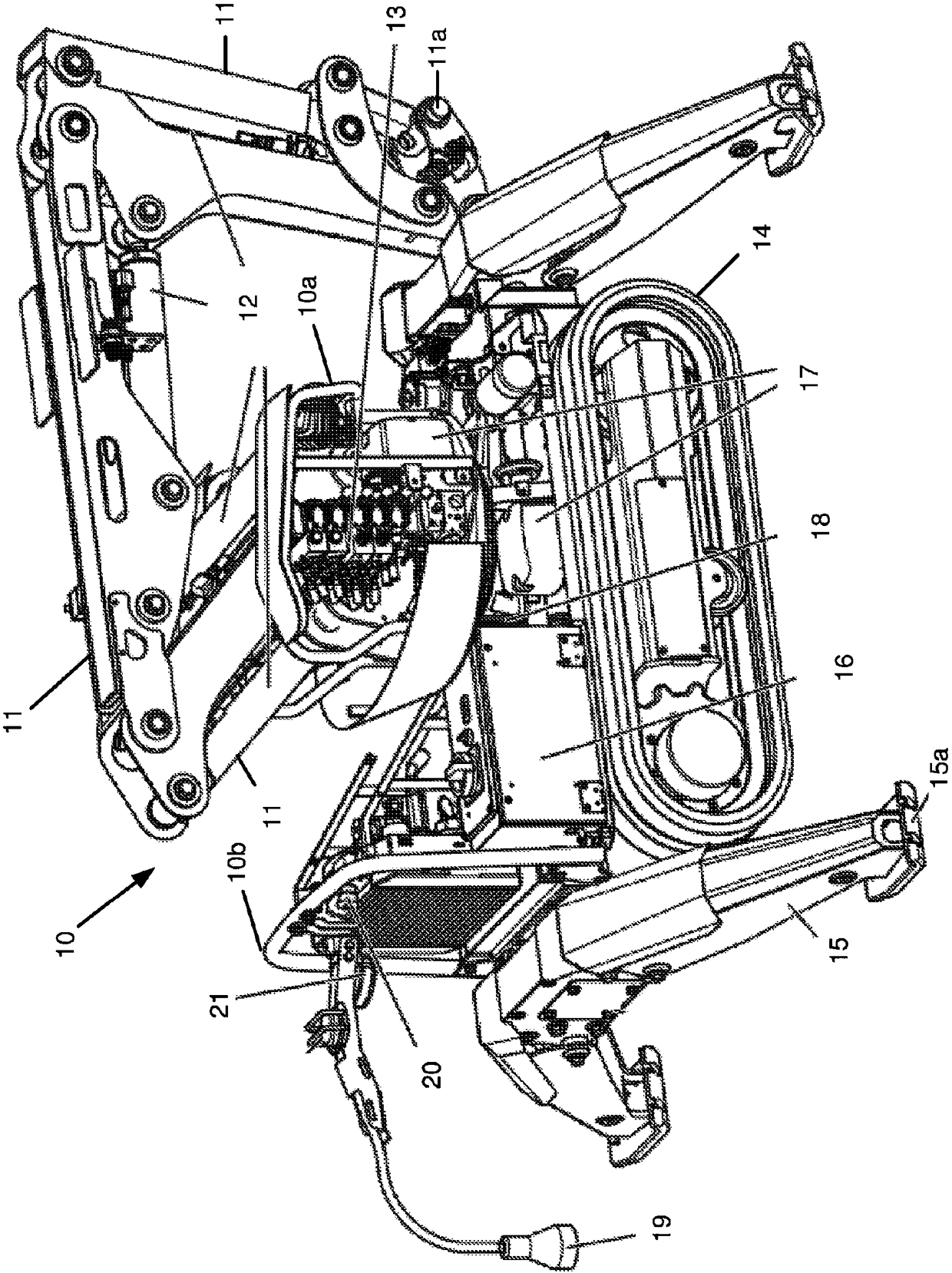

[0016] figure 1 A remote-controlled demolition robot 10 is shown, hereinafter simply referred to as robot 10 . The robot 10 comprises one or more robot parts, such as an arm 11, which can constitute one (or more) robot arm parts. A component can be used to hold the accessory 11b ( figure 1 not shown, see image 3 ) accessory tool holder 11a. The attachment 11b may be a tool such as a hydraulic breaker or hammer, cutter, saw, digging bucket or the like. An accessory may also be a load carried by the robot 10 . The arms 11 are movably operable by at least one cylinder 12 for each arm 11 . The cylinders are preferably hydraulic and are controlled via a hydraulic valve block 13 housed in the robot 10 .

[0017] The robot 10 includes tracks 14 that enable the robot 10 to move. Alternatively or additionally, the robot may have wheels for enabling its locomotion, wheels and tracks are examples of drive means. The robot also includes outriggers 15 which can be extended individ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com