Pressure-sensitive touch panel

A panel, capacitive touch technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problems of complex production cost, high cost, huge touch panel and other problems of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In the following description, similar components are designated by similar reference numerals.

[0073] Self-capacitance and pressure combined measurement

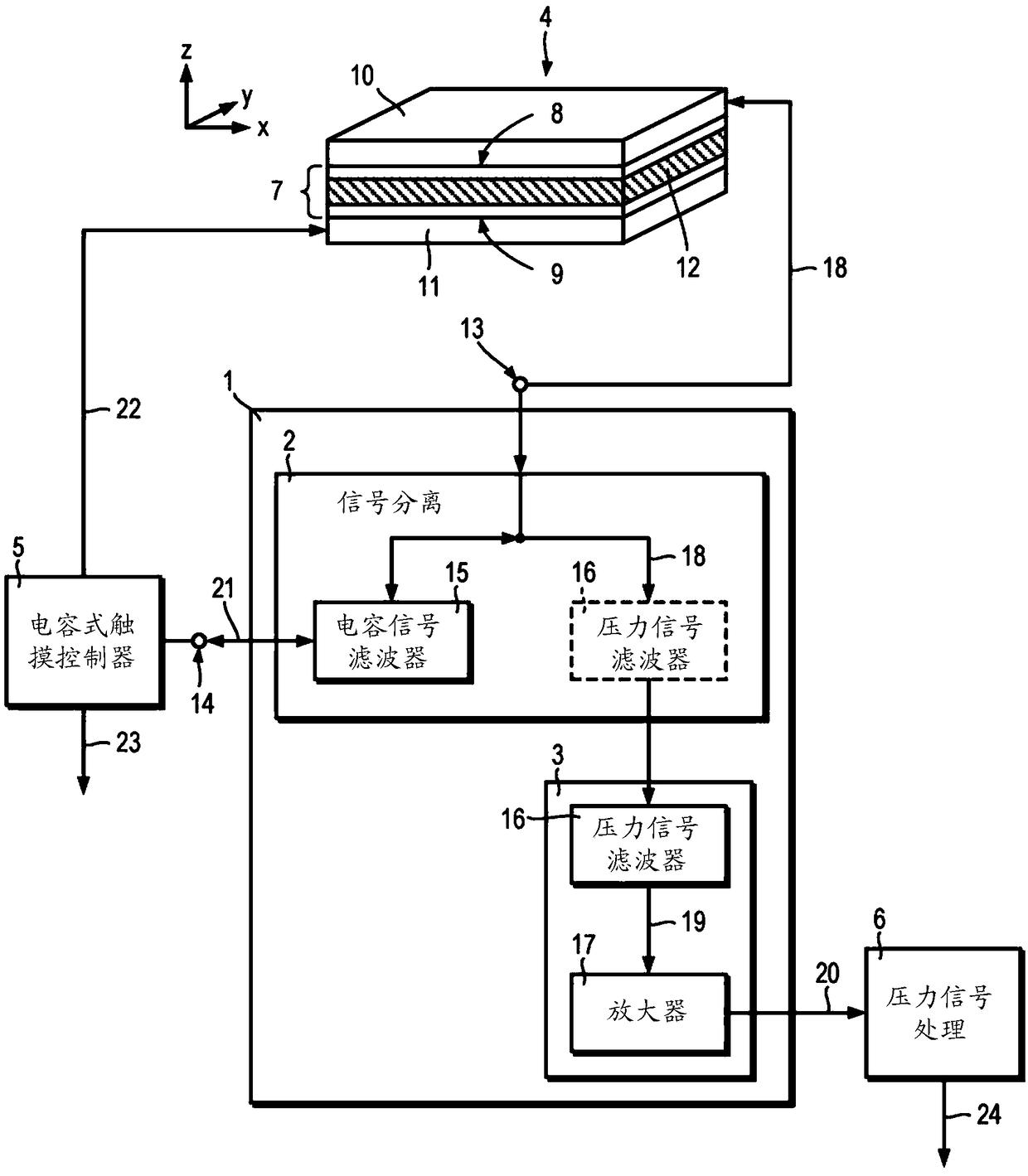

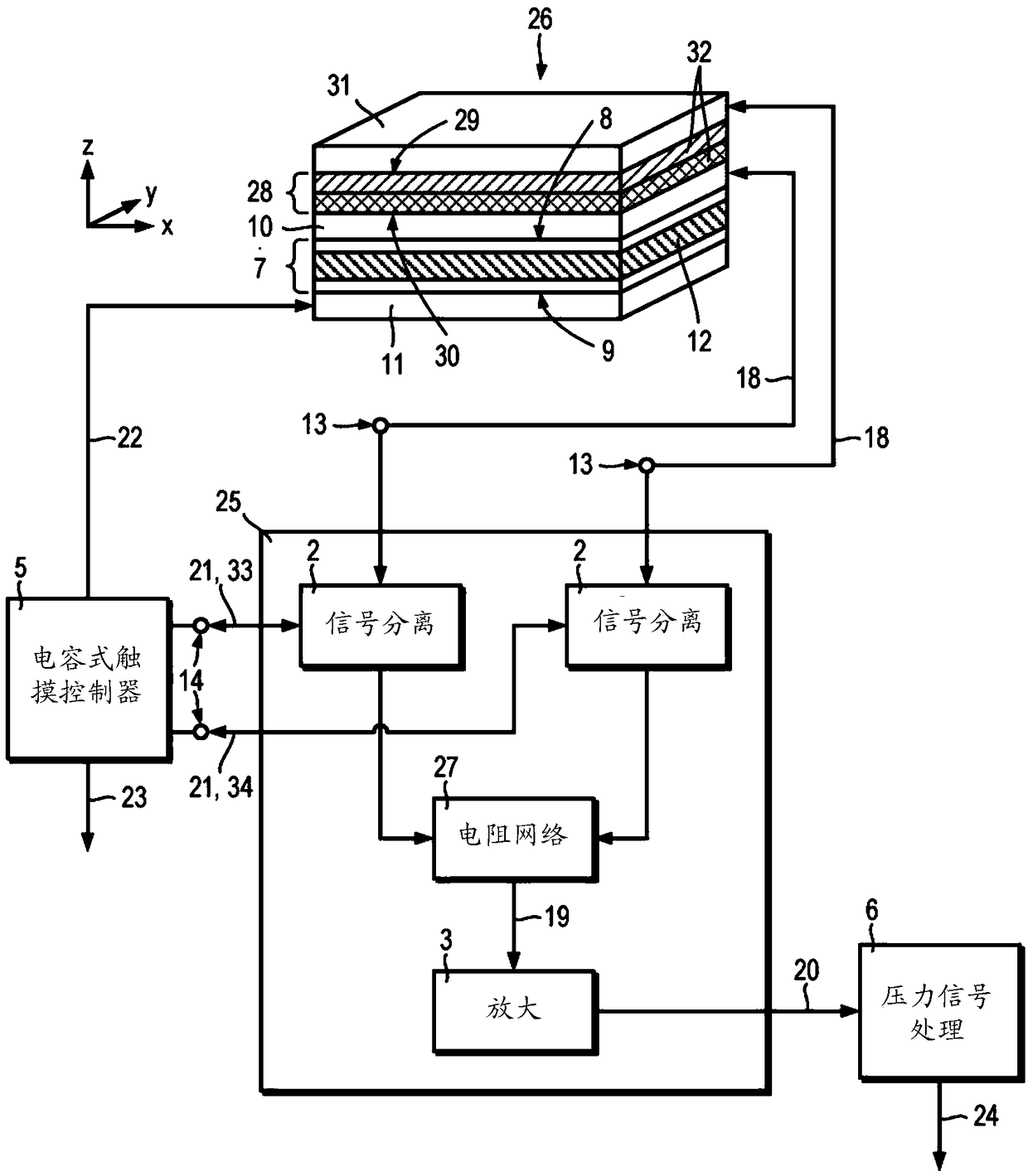

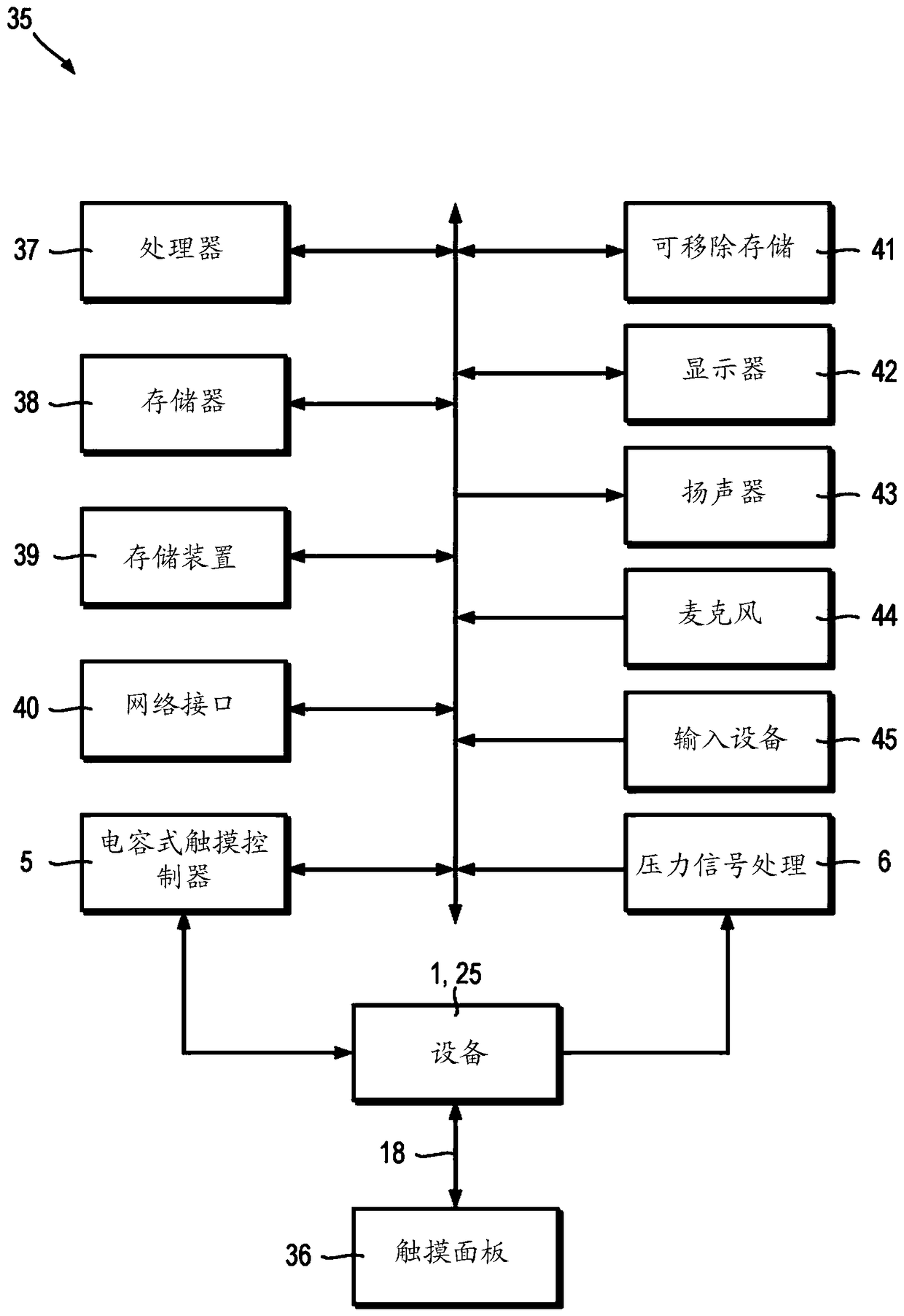

[0074] figure 1 A device 1 and a touch sensor 4 for combined capacitive and pressure measurements are shown.

[0075] see figure 1 , the device 1 for combined measurement of capacitance and pressure includes a signal separation stage 2 and an amplification stage 3 . The device 1 is connected to a touch sensor 4 , a capacitive touch controller 5 and a pressure signal processing module 6 . The device 1 enables capacitive and pressure measurements by the touch sensor 4 simultaneously using a pair of electrodes.

[0076] The first touch sensor 4 includes a layer structure 7 , a first sensing electrode 10 and a common electrode 11 , the layer structure 7 has a first surface 8 and a second surface 9 opposite to each other. The layer structure 7 comprises one or more layers comprising at least a layer 12 of piezoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com