An automatic continuous stamping device

A stamping device and automatic technology, applied in the field of stamping, can solve the problems of adjusting the production rhythm, hidden dangers of labor safety production, and lack of labor flexibility in enterprises, so as to improve production efficiency, avoid manual operations of loading and unloading, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

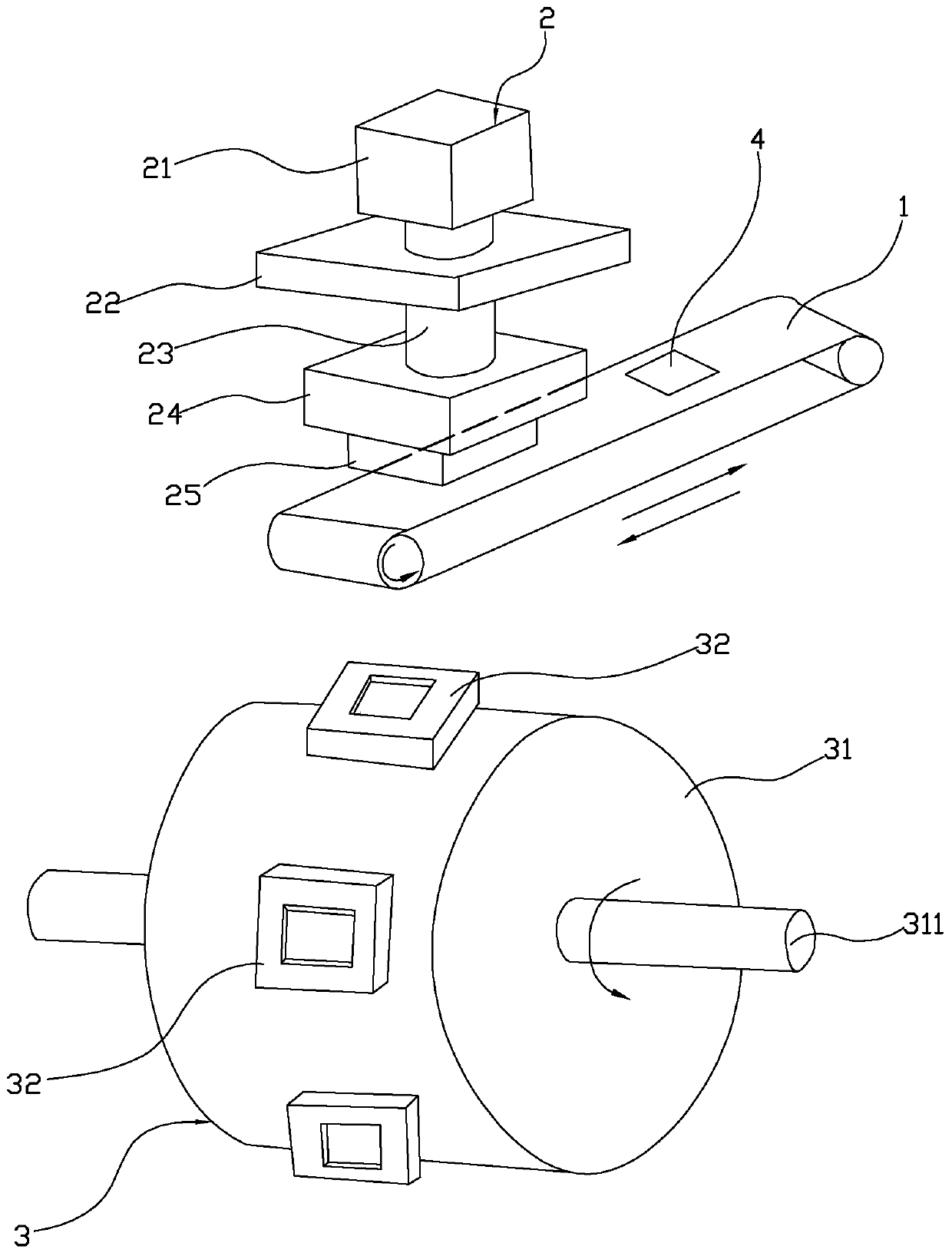

[0011] Such as figure 1 As shown, the automatic continuous stamping device in this implementation includes a conveyor belt 1 , a stamping assembly 2 , and a drum assembly 3 .

[0012] Wherein, the conveyor belt 1 is movable, the stamping assembly 2 is arranged above the conveyor belt 1, the drum assembly 3 is arranged below the conveyor belt 1, the stamping assembly 2 includes a fixed plate 22, a power source 21 arranged on the fixed plate 22, The punch 23 connected to the output end of the power source 21, the connecting block 24 arranged on the punch 23, the upper die 25 arranged below the connecting block 24, the shape of the cavity of the upper die 25 is the upper surface of the workpiece after complete stamping shape, the connecting block 24 is positioned at the back of the upper die 25 to be provided with an electromagnet; the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com