Porous bit industrial aluminum profile horizontal hydraulic punch press

A technology for hydraulic punching and aluminum profiles, applied in the field of door, window and curtain wall processing, can solve the problems of unfixed hole position specification and position of profiles, influence of machining accuracy, and inability to locate workpieces, so as to facilitate integration into the assembly line, high flexibility, and convenient workpiece exchange. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

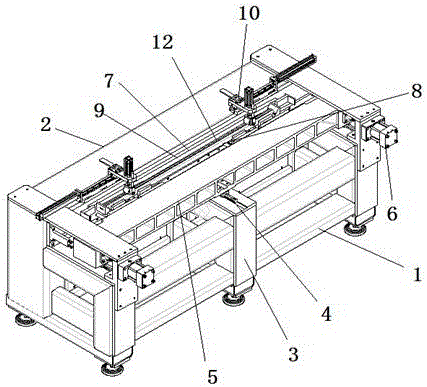

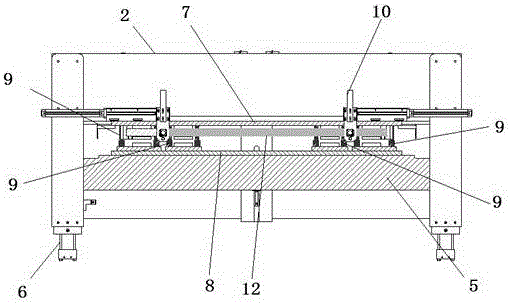

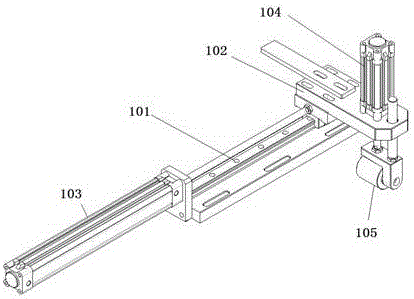

[0024] As shown in the figure, a horizontal hydraulic punch press for porous industrial aluminum profiles includes: base 1, bed 2, support column 3, main beam guide rail 4, main beam 5, main beam driving cylinder 6, lower template 7, upper Template 8, mold 9, vertical pressing mechanism 10, inclined-plane guide positioning block 11; described vertical pressing mechanism 10 includes: vertical mechanism sliding guide rail 101, sliding support 102, reset cylinder 103, vertical pressing cylinder 104 and pressing Material roller 105;

[0025] The connections of the above components are as follows:

[0026] In this embodiment, the bed 2 is vertically fixed on one side of the base 1; the support column 3 is fixed on the other side of the base; the top surface of the support column 3 is provided with a main beam guide rail 4, and the main beam 5 is vertically installed on the main beam guide rail 4; the main beam driving cylinder 6 drives the main beam 5 to perform reciprocating punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com