Automobile power assembly integrated frame

An automotive powertrain and frame technology, applied in electric vehicles, power units, electric power units, etc., can solve the problems of many assembly processes, large space occupation, inconvenient maintenance, etc., to improve the rigidity of the whole vehicle, save space, Install compact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and understandable, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be noted that the drawings of the present invention all adopt simplified forms and all use imprecise proportions, which are only used to conveniently and clearly assist in explaining the purpose of the embodiments of the present invention.

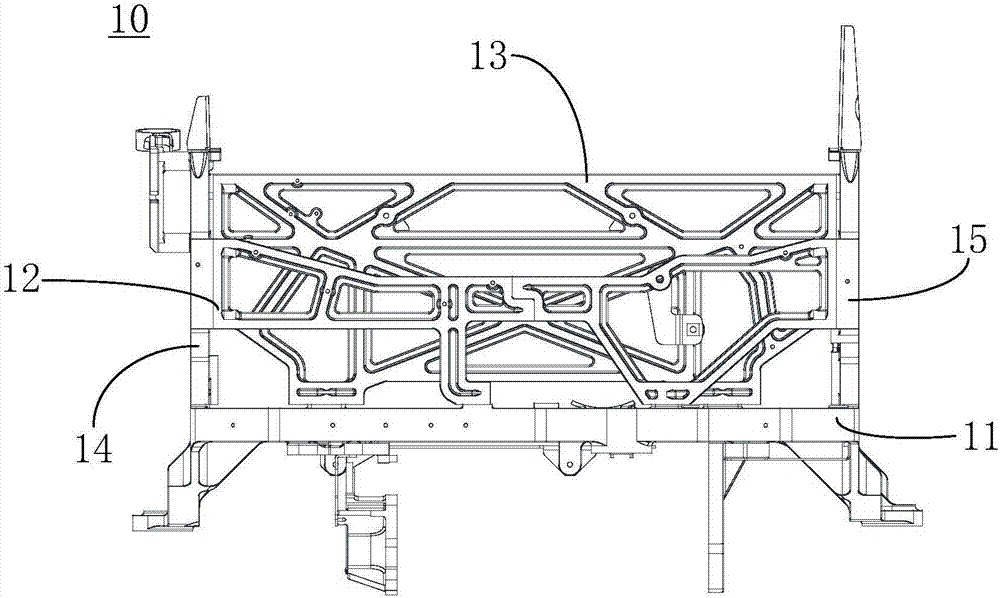

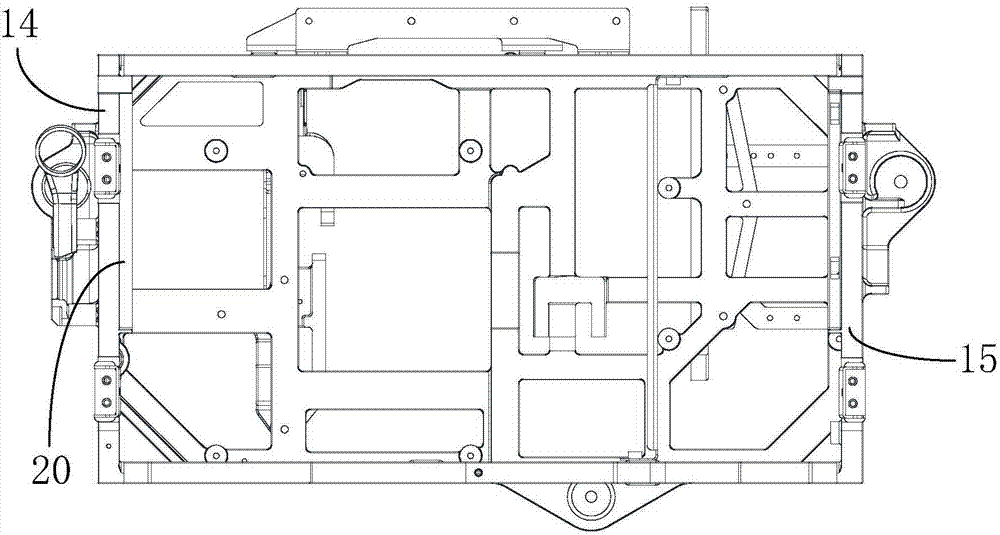

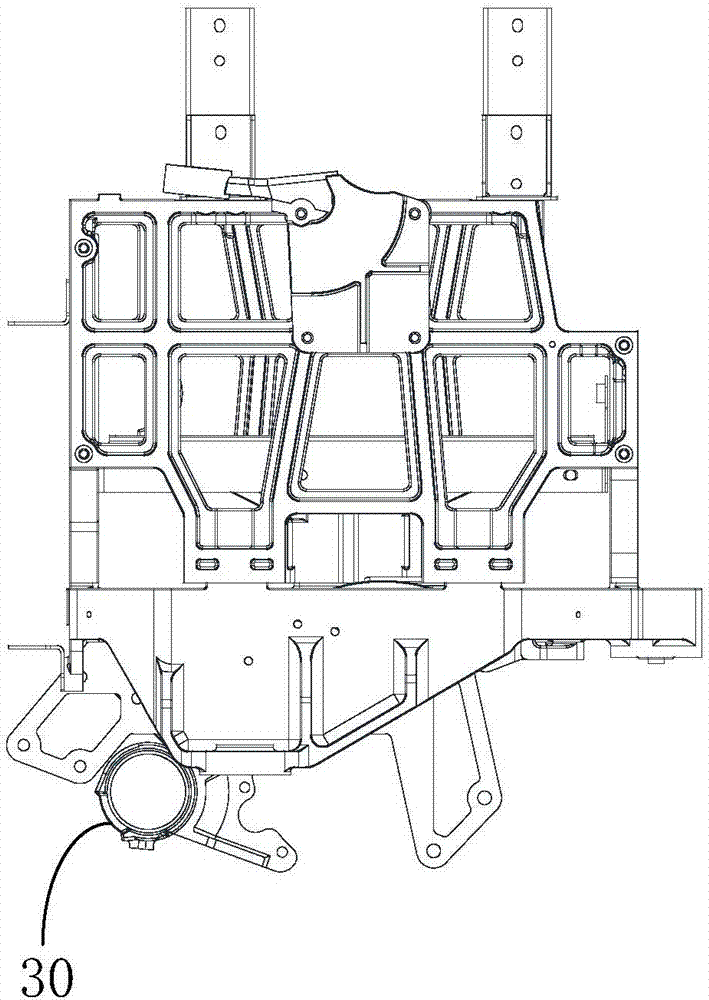

[0024] The automobile powertrain integration framework provided by the present invention, such as figure 1 As shown, the frame body 10 is composed of six brackets spliced together, and the six brackets are respectively a bottom bracket 11 arranged horizontally and a front bracket 12 arranged vertically on the four sides of the bottom bracket 11 , The rear bracket 13, the left bracket 14 and the right bracket 15. The frame body 10 divides the total power components into thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com