Dual-motor wire conveying device for FDM printer

A conveying device and dual-motor technology, which is applied in the direction of additive processing, 3D object support structure, metal processing equipment, etc., can solve the problems of unable to provide sufficient extrusion force nozzle, uneven surface, insufficient extrusion, etc., to shorten the printing time Time, light weight, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

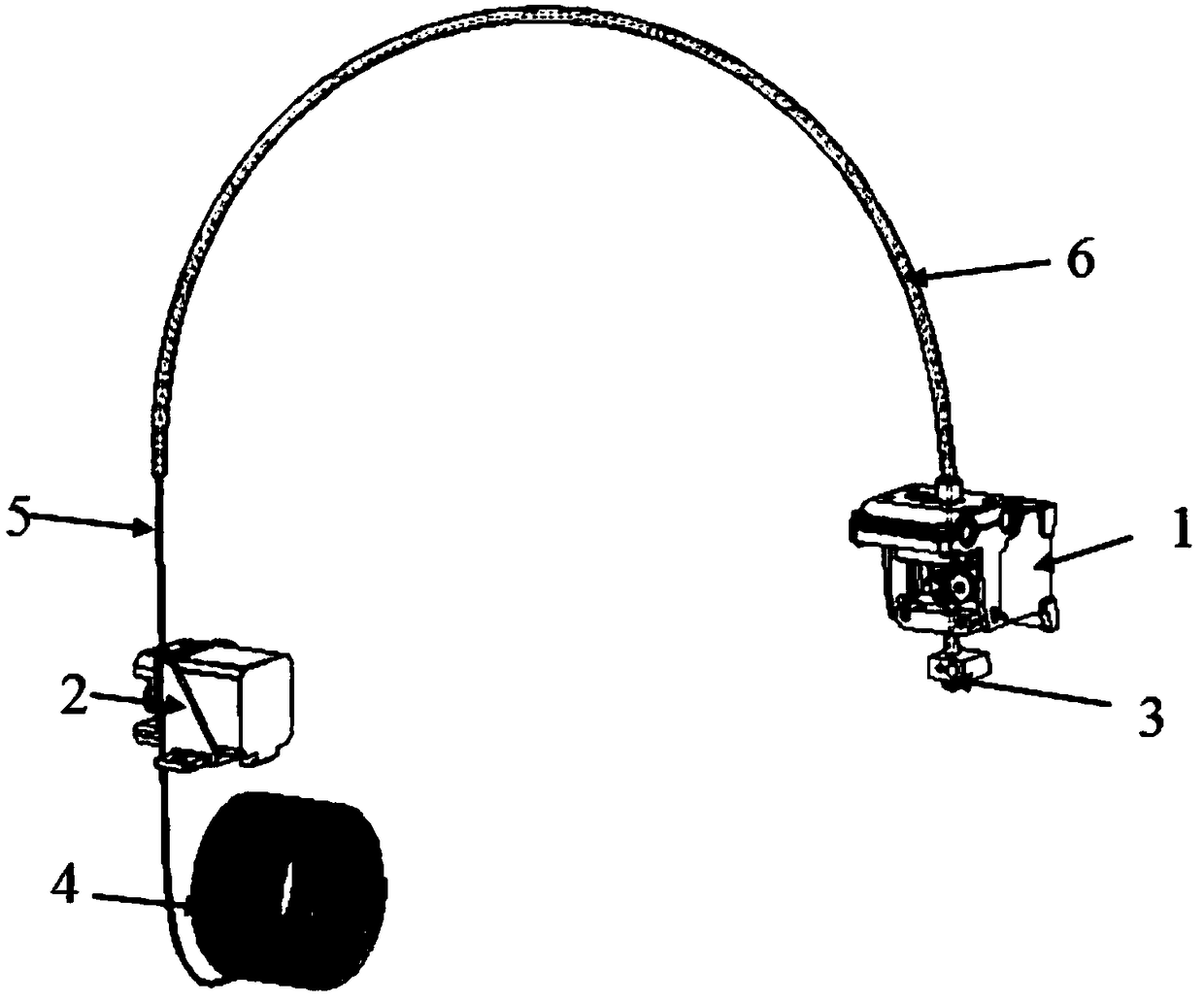

[0017] In conjunction with the accompanying drawings, a dual-motor wire conveying device for FDM printers includes a short-distance extrusion structure 1, a remote conveyance structure 2, a nozzle 3, a wire material disk 4, a wire 5 and a wire conduit 6, and the short-distance extrusion The other end of the short-distance extrusion structure 1 is connected to the wire guide 6, and the wire 5 passes through the wire material disk 4, the remote delivery structure 2 and the wire guide 6, and is subjected to close The pulling force provided by the extrusion structure 1 passes through the nozzle 3.

[0018] The remote conveying structure 2 drives the wire material disc 4 to rotate by pulling the wire 5 .

[0019] The proximal extrusion structure 1 includes a first motor, and the remote delivery structure 2 includes a second motor.

[0020] The transmission line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com