Dyeing Process of Mercerized Cotton Yarn

A cotton yarn and process technology, applied in the field of mercerized cotton yarn dyeing process, can solve the problems of waste of water resources, prolonged dyeing process, messy accumulation, etc., and achieve the effects of preventing scorching, improving vividness, and improving operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

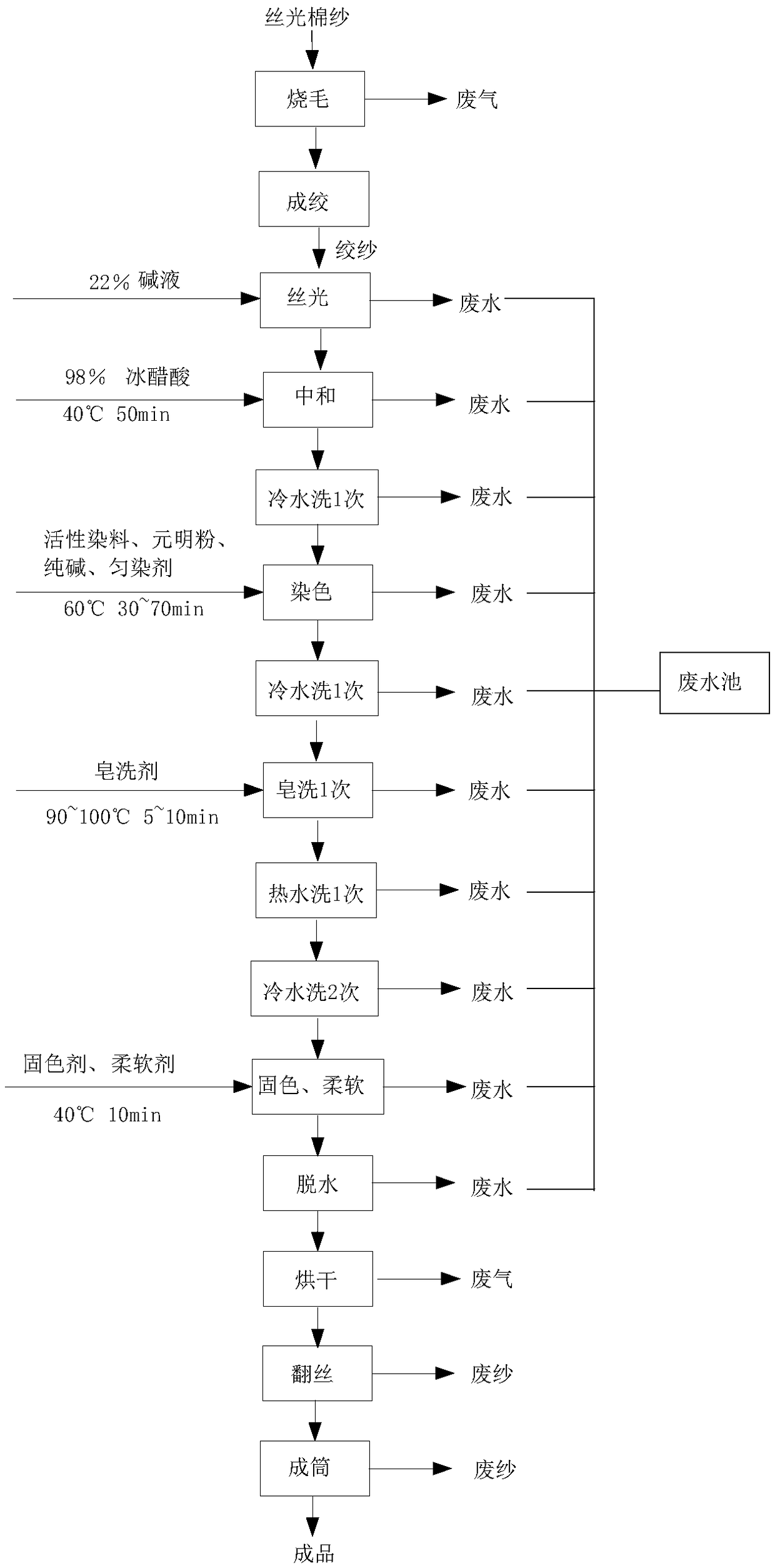

[0033] Embodiment, a kind of mercerized cotton yarn dyeing process, such as figure 1 shown, including the following steps:

[0034] Step 1, pretreatment: Use a natural gas singeing machine to remove the fluff formed on the surface of the yarn, and connect the exhaust fan to extract the exhaust gas; after that, the yarn is processed into a neat skein through the skein forming machine, which is convenient for subsequent processing.

[0035] Specifically, by controlling the pressure of the natural gas to adjust the size of the flame, the fluff is removed to make the yarn smooth and beautiful, and the elasticity of the yarn is improved. The exhaust fan extracts the waste gas produced by singeing in time, which is convenient for centralized treatment of waste gas and reduces air pollution in the production workshop.

[0036] Step 2, mercerizing treatment: take the skein treated in step 1 and put it into a mercerizing machine, paddle it with lye for 5 minutes, then rinse it with ho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap