Reconstituted tobacco for devices that heat tobacco without burning it

A technology for reconstituting tobacco and tobacco, applied in directions such as tobacco, tobacco processing, application, etc., can solve problems such as being difficult to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In a laboratory at 40°C in a water bath, a mixture of Virginia tobacco, Burley tobacco and Oriental tobacco leaves was brought into contact with water and manually stirred for 30 min. The water soluble components are separated from the fiber fraction by mechanical pressing. It has a dry matter concentration of about 5%. The water soluble fractions were concentrated under vacuum to a dry substance concentration of 47%. Glycerin is added to the tobacco water soluble components to obtain about 20% by weight in the final reconstituted tobacco.

[0061] Simultaneously, the Virginia stems were contacted with water for 30 minutes in a water bath at 80°C. The water soluble components are separated from the fibrous fraction by mechanical pressing and discarded.

[0062] Tobacco lamina fibers and tobacco stem fibers with added water and 10% lignocellulosic slurry expressed as wt% of the extracted tobacco blend were mixed and transferred to a refiner. The fibers were refined f...

Embodiment 2

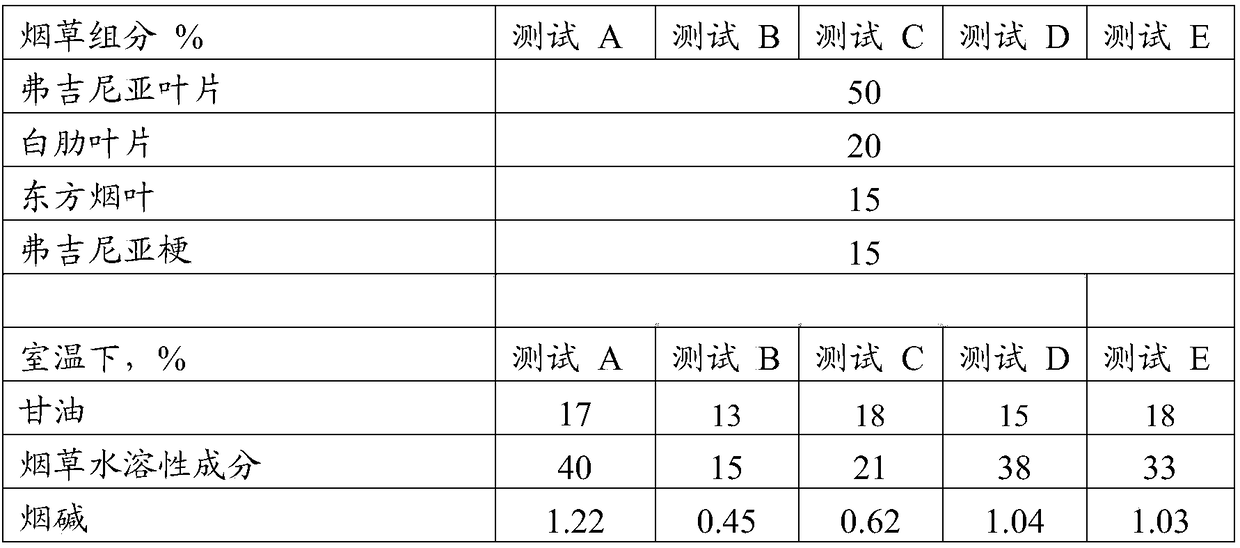

[0067] In a laboratory at 85°C in a water bath, a mixture of Virginia tobacco, Burley tobacco and Oriental tobacco leaves was brought into contact with water and manually stirred for 30 min. The water soluble components are separated from the fiber fraction by mechanical pressing. It has a dry matter concentration of about 7%. The water soluble components were concentrated under vacuum. Glycerin is added to the tobacco water soluble components to obtain about 13%-18% by weight in the final reconstituted tobacco.

[0068] Tobacco fibers with added water and 8% lignocellulosic slurry expressed as % by weight of the extracted tobacco blend were mixed and transferred to a refiner. The fibers were refined for about 17 minutes.

[0069] Tobacco fiber sheets were formed on a laboratory paper machine. Glycerin is added to the concentrated water soluble ingredients. A concentrated tobacco water soluble ingredient comprising glycerin is added to the tobacco fiber sheet by dipping i...

Embodiment 3

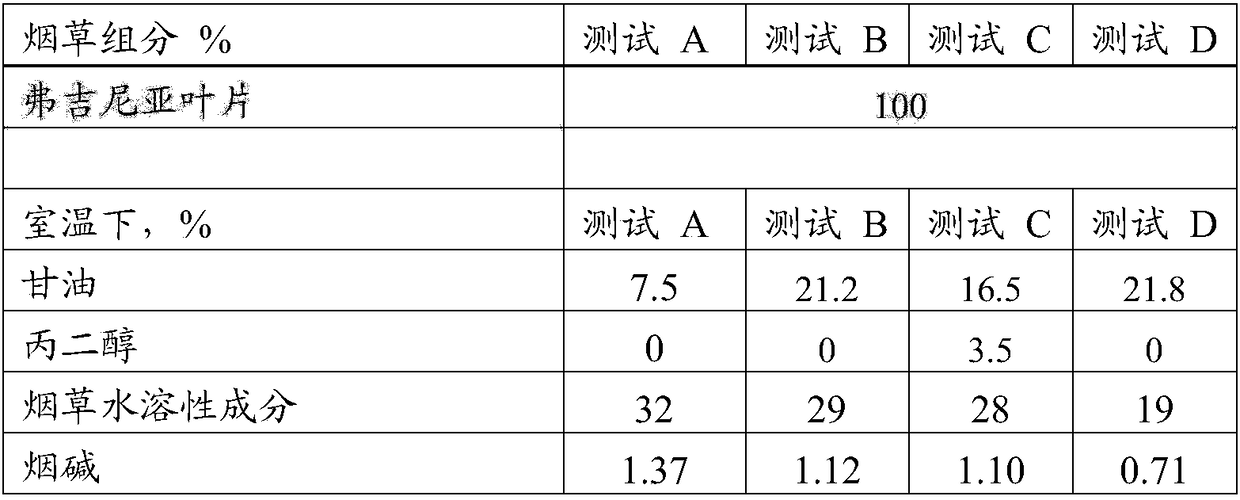

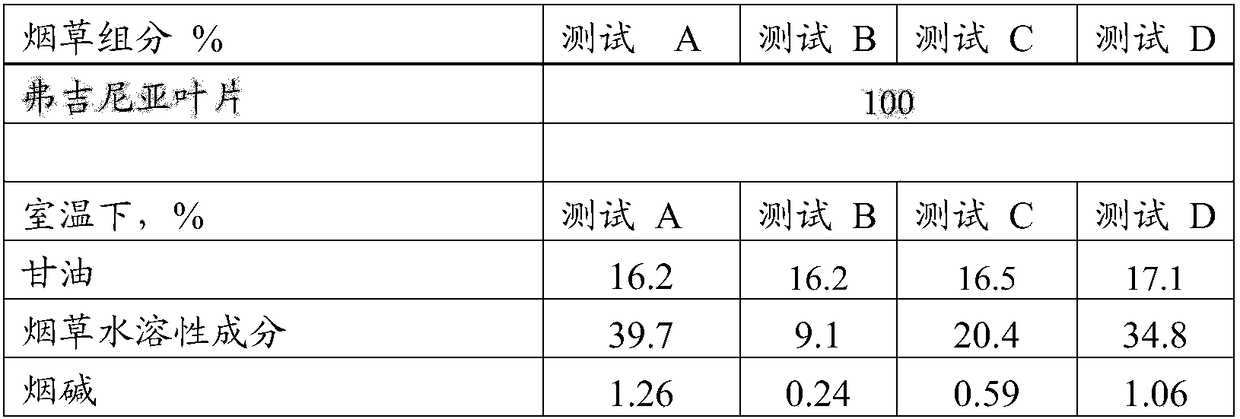

[0075] The various Virginia leaves were contacted with water in a laboratory at 85°C in a water bath with manual agitation for 30 min. The water soluble components are separated from the fiber fraction by mechanical pressing. It has a dry matter concentration of about 8%. The water soluble components were concentrated under vacuum. Glycerin or glycerin and propylene glycol are added to the tobacco water soluble components to obtain 7.5% to 21.8% by weight in the final reconstituted tobacco.

[0076] Tobacco fibers with added water and 8% lignocellulosic slurry expressed as % by weight of the extracted tobacco blend were mixed and transferred to a refiner. The fibers were refined for about 20 minutes.

[0077] Tobacco fiber sheets were formed on a laboratory paper machine. Add glycerin or glycerin and propylene glycol to the concentrated water-soluble ingredients. Concentrated tobacco water soluble ingredients including humectants are added to the tobacco fiber sheet by di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com