Water volume adjusting equipment

A technology of water volume adjustment and adjustment equipment, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor filtration effect of filter components, fluctuation of water pressure in the water inlet pipe network, inflexible adjustment of water intake, etc. To achieve the effect of reducing water inflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

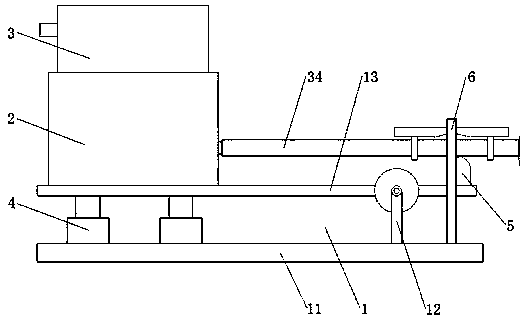

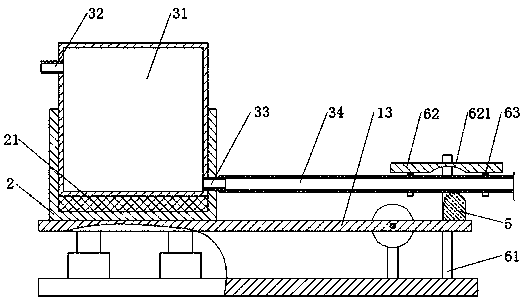

[0038] A water volume regulating device, characterized in that the regulating device comprises:

[0039] The main frame 1, the main frame 1 includes

[0040] base 11;

[0041] A vertical pole 12, the vertical pole 12 is located on the base 11, and the lower end of the vertical pole 12 is fixedly connected to the base 11;

[0042] A horizontal plate 13, the horizontal plate 13 is placed horizontally, and the middle part of the horizontal plate 13 is hinged to the upper end of the vertical rod 12, and the horizontal plate 13 is turned left and right relative to the vertical rod 12;

[0043] Specifically, the main frame 1 is made of metal, generally a steel plate or an iron plate. A seesaw structure is formed between the horizontal plate 13 and the vertical rod 12. Through the change of the weight on both sides, the horizontal plate 1 13 automatic flip.

[0044] A water storage assembly 3, the water storage assembly 3 is located above the left side of the horizontal plate one ...

Embodiment 2

[0067] Embodiment two, on the basis of embodiment one, further optimization, specifically

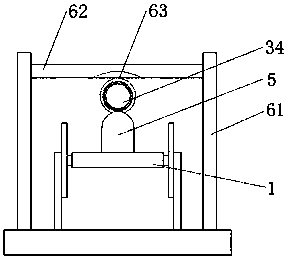

[0068] The adjustment device also includes a winding frame 7, which is frame-shaped, and the winding frame 7 includes

[0069] The third pole 71, the third pole 71 is located on the base 11, and the lower end of the third pole 71 is connected to the base 11;

[0070] Roller 72, the upper end of the roller 72 and the vertical rod three 71 is hinged, and the roller 72 is free to roll relative to the vertical rod three 71;

[0071] Wherein, the water outlet pipe 34 is coiled and hangs on the roller 72 , and the part of the water outlet pipe 34 on the roller 72 is the water outlet pipe winding portion 341 .

[0072] Specifically, the winding part 341 of the water outlet pipe has a stretching amount, which can adjust the overall length of the water outlet pipe 34, which facilitates the connection between this equipment and traditional water treatment equipment. less wear and prolong life. ...

Embodiment 3

[0073] Embodiment three, further optimization on the basis of embodiment one or two, specifically

[0074] The base 11 is provided with a pillar 4 relative to the left side of the horizontal plate 13. The pillar 4 is elastically telescopic, the upper end of the pillar 4 is connected to the horizontal plate 13, and the lower end of the pillar 4 is connected to the base 11. .

[0075] The pillar 4 includes a bottom column part 41; a telescopic part 42, the telescopic part 42 is located above the bottom column part 41, and stretches up and down relative to the bottom column part 41; a spring 43, and the spring 43 is located at the bottom column part Between 41 and the telescopic part 42; a limiting member 44, the limiting part 44 is arranged on the exposed part of the telescopic part 42 relative to the bottom column part 41, and the telescopic part 42 is fixedly connected.

[0076] Specifically, the structure of the pillar 4 is a spring 43 telescopic column structure, and the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com