Fixtures for Turning Ball Head Shaft Parts

A ball head shaft and fixture technology, which is applied to metal processing mechanical parts, clamping, manufacturing tools, etc., can solve the problems of difficulty in subsequent processing of parts, and achieve the effect of fast and convenient clamping, ensuring accuracy, and a reliable and stable fixing method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

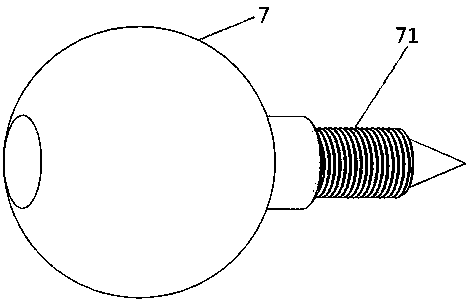

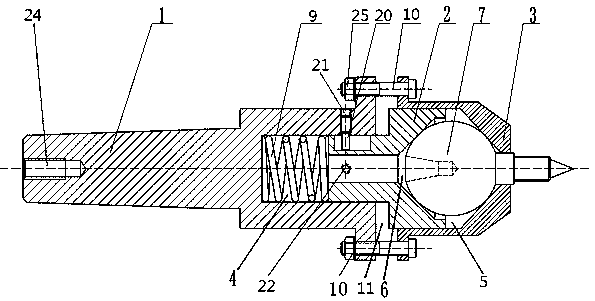

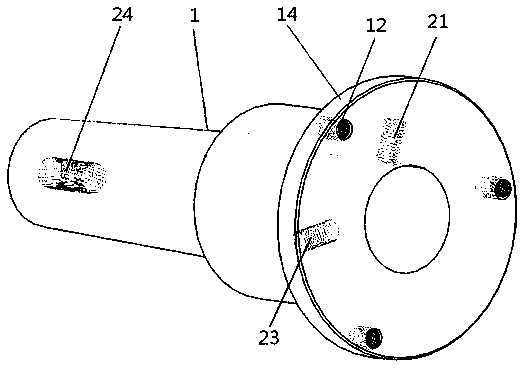

[0022] Such as figure 1 , 2 , 3, 4, 5, and 6 are the fixtures for the turning ball shaft parts, including the fixture main body 1, the support body 2 and the gland 3, and the support body 2 is a stepped shaft structure, which is hollow in this embodiment to save materials Structure. The small-diameter section at the back of the support body 2 is inserted into the blind guide hole 4 provided on the front end of the fixture body 1, and the large-diameter section at the front of the support body 2 is inserted into the guide hole 5 provided on the rear end surface of the gland 3. Inside, the guide hole 5 includes a circular guide portion at the front end and a tapered clamping portion at the rear end, and a tapered positioning groove 6 is provided on the front surface of the support body 2, and the tapered positioning groove 6 is fixed with the tapered clamping portion. The part clamps and fixes the ball head 7 of the part. The gland 3 is provided with an axial through hole 8 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com