A shift curve determination method avoiding tractor shift cycle

A technology of shifting curve and determining method, which is applied in mechanical equipment, components with teeth, transmission control and other directions to achieve the effects of improving shifting smoothness, avoiding shifting cycles, and reducing the number of slips and frictions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

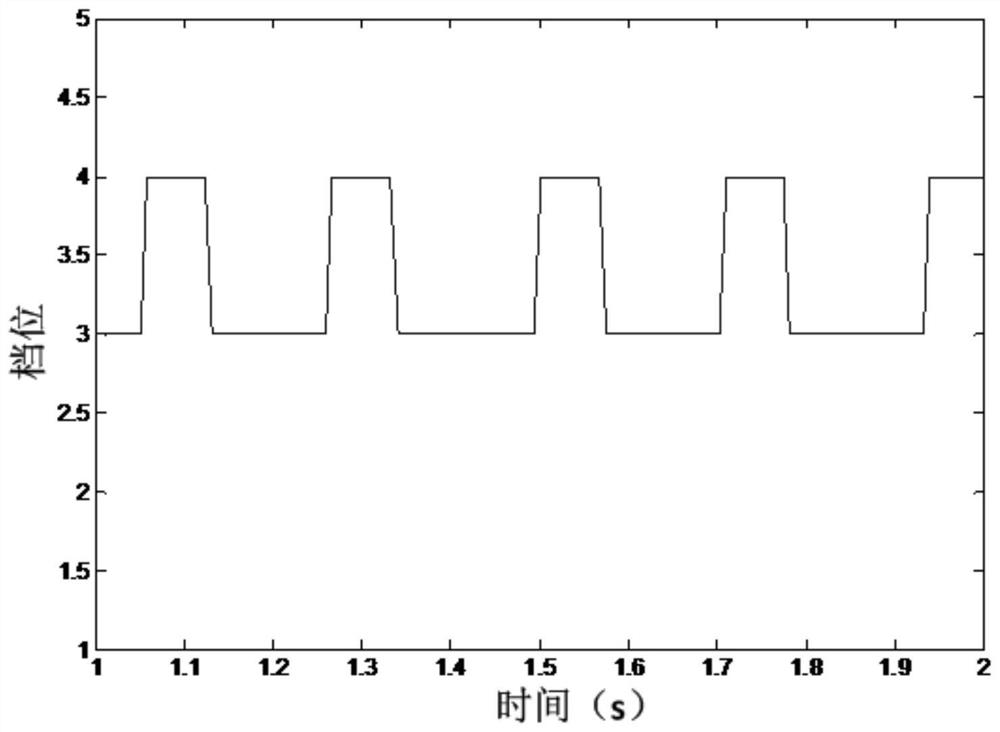

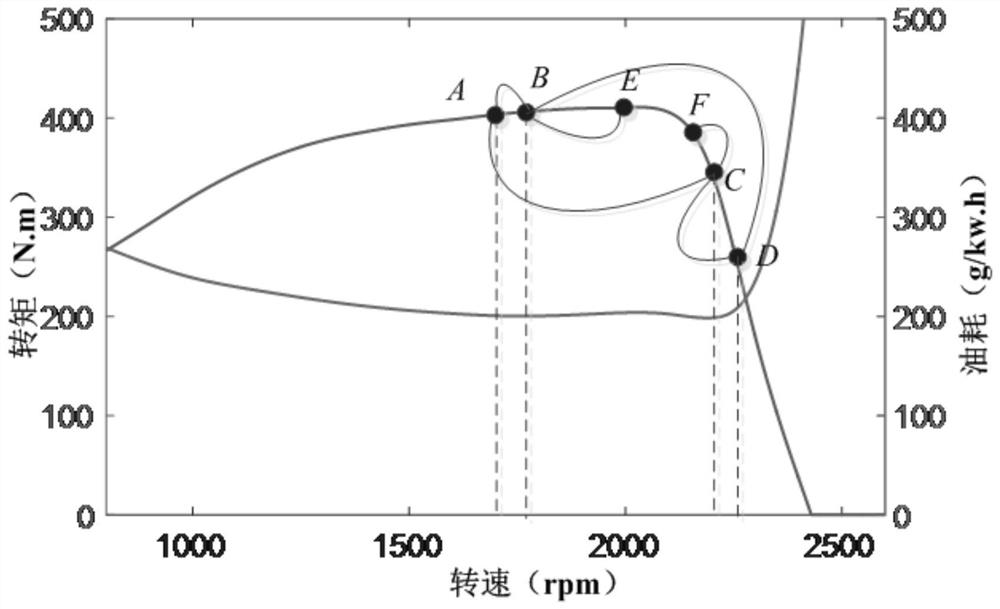

[0046] see Figure 5-7 , a tractor with a four-speed power shift transmission, the power of the matching diesel engine is 58.8kw, and the speed-torque curve of the engine under different throttle openings is fitted according to the experimental data of the engine bench.

[0047] Determine the upshift point and downshift point of the transmission and the corresponding speed of the output shaft of the transmission according to the engine speed-torque curve fitted under different throttle openings according to the engine bench test data

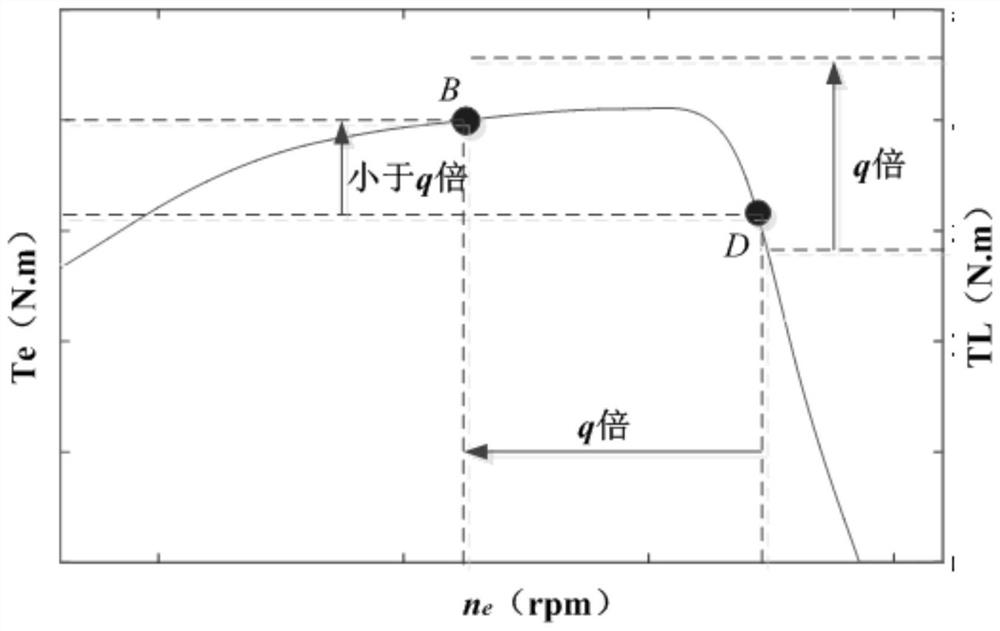

[0048] When taking k T = 1,k w =1, namely: T D =T A / q,n A =n D q, and then determine the output shaft speed of the transmission at the upshift point and downshift point under different throttle openings according to the speed-torque curve, and fit it to the upshift curve under this parameter.

[0049] When taking k T = 1,k w =1.01, namely: T D =T A / q,n A =1.01n D q, and then determine the output shaft speed of the transmission at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com