Rotary control valve with high flow controllability

A technology for controlling valves and flow, which is applied in the direction of valve lift, valve details, valve devices, etc. It can solve the problems of inability to flexibly control medium flow, large noise, etc., so as to improve the controllability of low opening degree, maintain and install stably, The effect of relative rotation transition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

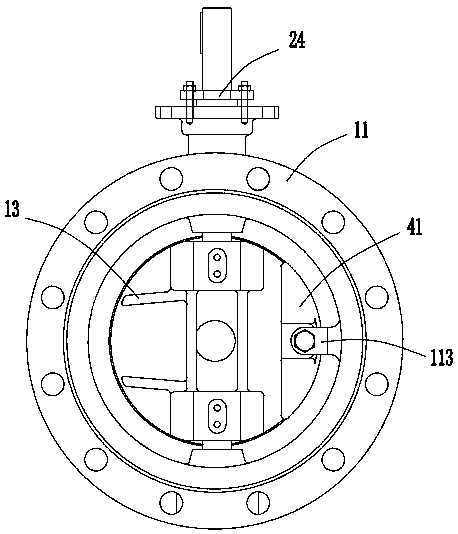

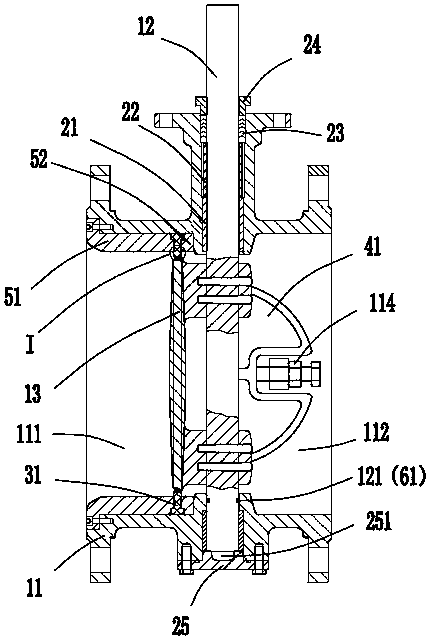

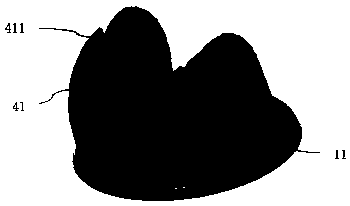

[0031] Such as figure 1 with figure 2 As shown, a rotary control valve with strong flow controllability includes a valve body 11, a valve stem 12 and a valve plate 13. The valve stem 12 runs through the top and bottom of the valve body 11 and connects with the valve body 11 through a bearing 21 at the penetrating position. Connection, specifically, at the penetrating position between the valve stem 12 and the top of the valve body 11, a ring sleeve 22, a V-shaped ring 23 and a packing gland 24 stacked on the bearing 21 are sequentially arranged, and the bottom of the valve body 11 is connected to the valve stem 12. The mounting end is provided with a bottom cover 25 for closing the valve body 11, and the contact surface between the bottom cover 25 and the valve stem 12 has a groove 251; the valve body 11 includes a medium inlet 111 and a medium outlet 112, and the valve body 11 at the medium inlet end is installed with The rubber sealing ring 31 adapted to the valve plate 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com