A feed-adjustable pre-mixing concentrate nozzle

A premixed, concentrate technology, applied in the field of copper smelting, can solve the problems of uneven mixing of gas particles in a flash furnace, increase production safety, insufficient combustion, etc., and achieve easy production operation, safe smelting process, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

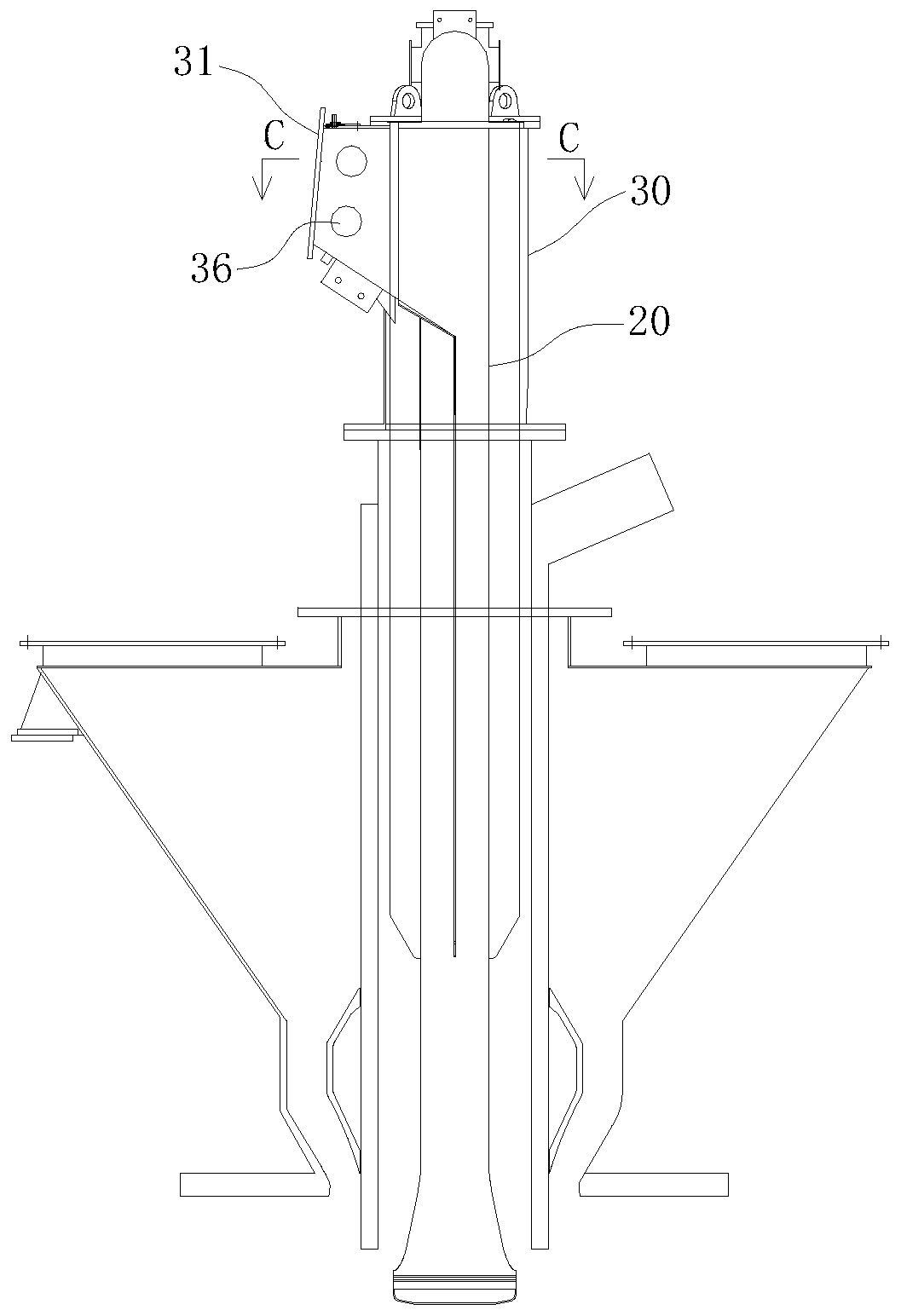

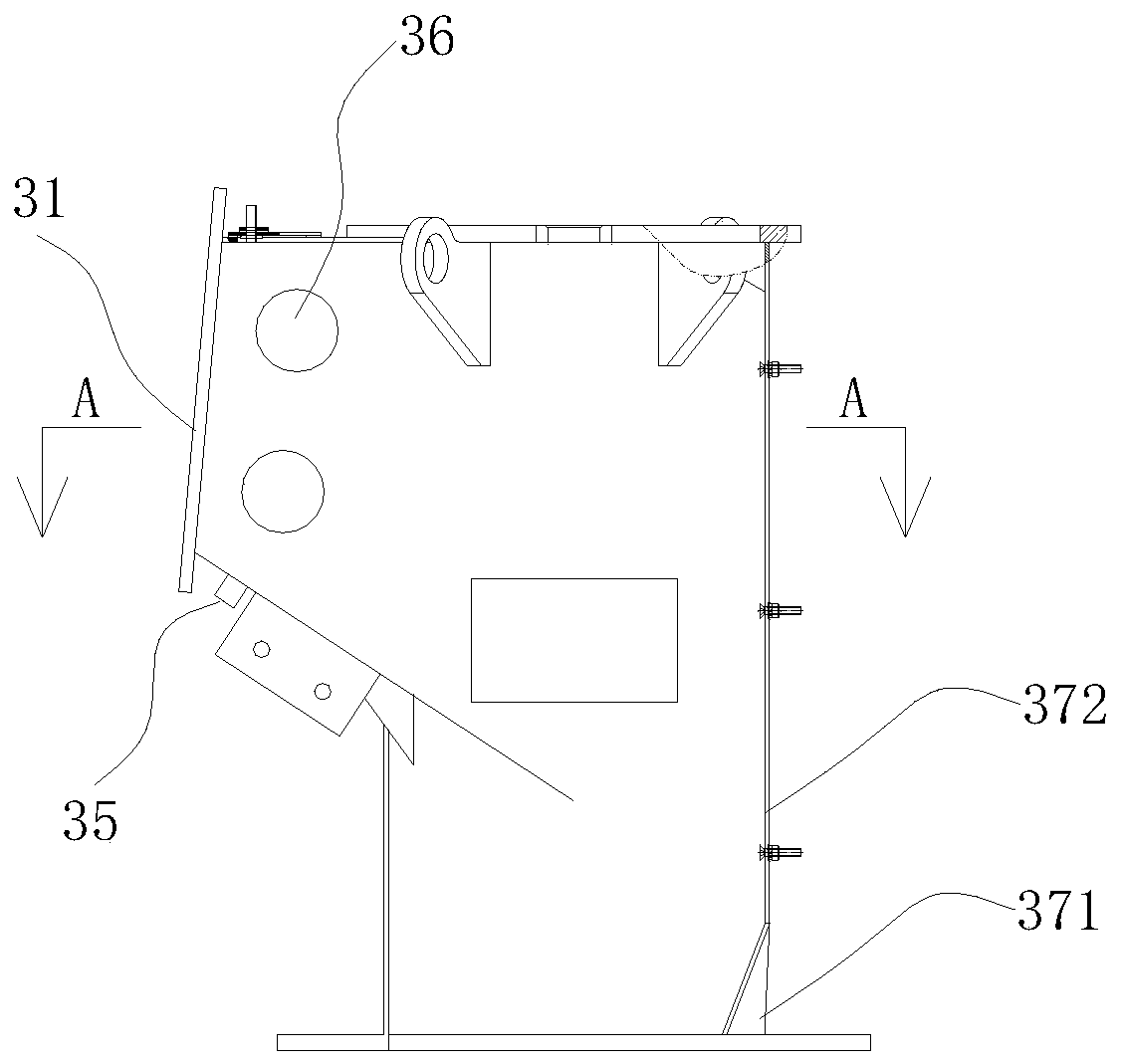

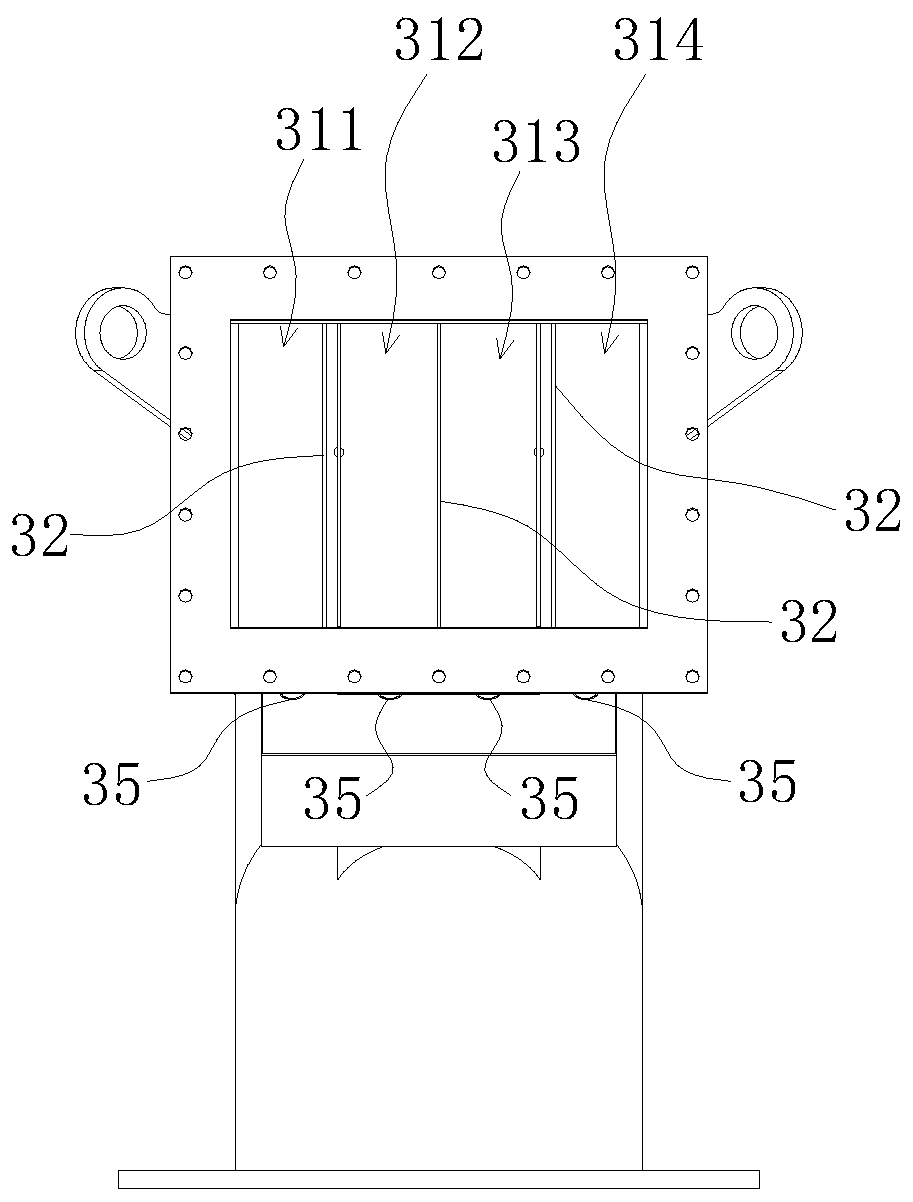

[0042] The present invention includes oxygen supply pipes 10 and dispersing air pipes 20 arranged vertically, overlapping tube cores, and arranged sequentially. The outer wall of the dispersing air pipe 20 is provided with a feeding box 30 , and the side of the feeding box 30 is There is a feeding port 31 that is inclined to feed downward, and the inside of the feeding box 30 is provided with a vertically arranged material distribution plate 32 that divides the feeding port 31 into a plurality of feeding ports. The width of the feeding port is The adjustment is realized by the rotation of the material distribution plate 32 , and the material feeding channel corresponding to the material feeding port guides the mineral material into the designated material cavity in the material feeding box 30 .

[0043] The present invention adjusts the width of each fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com