Production process for casting finished products through complex smelting of aluminum alloy chips

A production process and technology of aluminum alloy melt, applied in the field of aluminum alloy casting, can solve the problems of high processing cost and high energy consumption, and achieve the effects of improving quality, reducing impurity content and avoiding excessive furnace pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

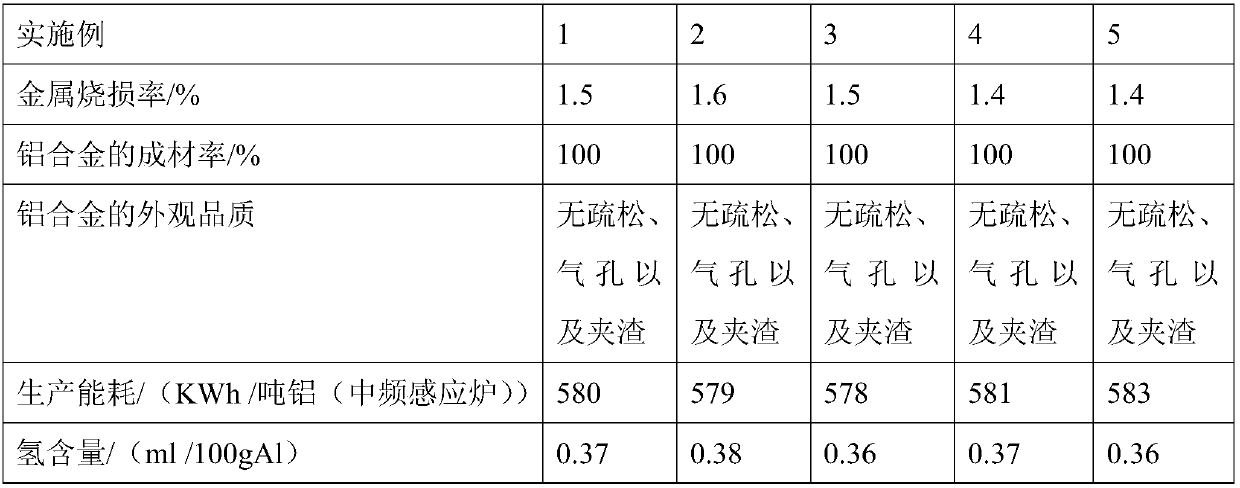

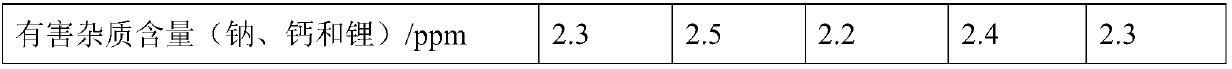

Examples

Embodiment 1

[0032] A production process of aluminum alloy debris remelting smelting and casting finished products, comprising the following steps:

[0033] Step 1. Degreasing: remove the residue and impurities from the aluminum alloy scraps and put them into an ultrasonic cleaner for at least 30 minutes. 2 times, filter to obtain the aluminum alloy debris after degreasing for use;

[0034] Step 2. Drying: Pour the degreased aluminum alloy scraps into the rotary furnace for baking in Step 1. The aluminum alloy scraps are turned over in the rotary furnace, and the liquid in the aluminum alloy scraps is in the rotary furnace. After being gasified or carbonized, the flue gas is discharged out of the furnace from the flue gas collection and treatment system. At the same time, the dried aluminum alloy chips fall into the bottom of the rotary kiln under the action of gravity. 20ppr / min, until no smoke is discharged from the smoke collection and treatment system, and dry aluminum alloy scraps ar...

Embodiment 2

[0039] A production process of aluminum alloy debris remelting smelting and casting finished products, comprising the following steps:

[0040] Step 1. Degreasing: Put the aluminum alloy shards into an ultrasonic cleaner for at least 30 minutes after removing the residual impurities. 2 times, filter to obtain the aluminum alloy debris after degreasing for use;

[0041] Step 2. Drying: Pour the degreased aluminum alloy scraps into the rotary furnace for baking in Step 1. The aluminum alloy scraps are turned over in the rotary furnace, and the liquid in the aluminum alloy scraps is in the rotary furnace. After being gasified or carbonized, the flue gas is discharged out of the furnace from the flue gas collection and treatment system. At the same time, the dried aluminum alloy chips fall into the bottom of the rotary kiln under the action of gravity. 50ppr / min, until no smoke is discharged from the smoke collection and treatment system, and dry aluminum alloy scraps are obtaine...

Embodiment 3

[0046] A production process of aluminum alloy debris remelting smelting and casting finished products, comprising the following steps:

[0047] Step 1. Degreasing: remove the residue and impurities from the aluminum alloy scraps and put them into an ultrasonic cleaning device for ultrasonic cleaning for at least 30 minutes. 2 times, filter to obtain the aluminum alloy debris after degreasing for use;

[0048] Step 2. Drying: Pour the degreased aluminum alloy scraps into the rotary furnace for baking in Step 1. The aluminum alloy scraps are turned over in the rotary furnace, and the liquid in the aluminum alloy scraps is in the rotary furnace. After being gasified or carbonized, the flue gas is discharged out of the furnace from the flue gas collection and treatment system. At the same time, the dry aluminum alloy chips fall into the bottom of the rotary kiln under the action of gravity. 40ppr / min, until no smoke is discharged from the smoke collection and treatment system, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com