A kind of welding seam forming quality monitoring method

A technology of forming quality and training methods, applied in welding equipment, biological neural network models, instruments, etc., can solve the problems of human subjectivity and hysteresis, and achieve the effect of easy computer implementation, simple learning rules, and easy on-site use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

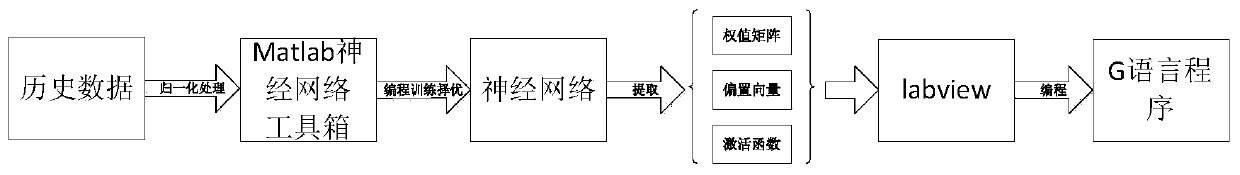

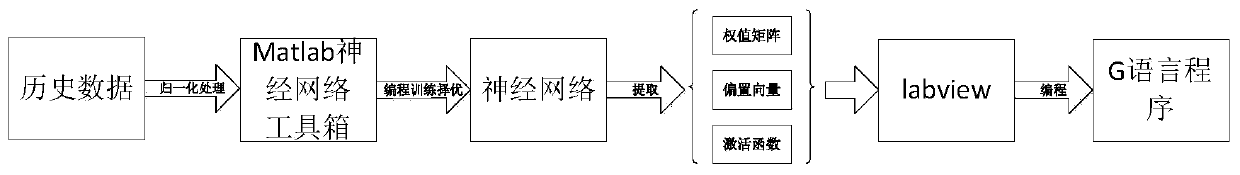

Method used

Image

Examples

Embodiment

[0040] Three typical situations measured: the fusion width is qualified, the penetration depth / reinforcement is unqualified, the penetration depth is qualified, the fusion width / reinforcement is unqualified, the reinforcement is qualified, and the fusion width / depth is unqualified. There are 36 groups of data in total. In this case, 12 groups of data are used as training input data, and the output is defined as (1,0,0), (0,1,0), (0,0,1) respectively.

[0041] According to the kolomogorov theorem: in a three-layer network, the number p of neurons in the hidden layer and the number n of neurons in the input layer satisfy the approximate relationship of p=2n+1. Since n=4, it can be concluded that p=9, The number of neurons in the output layer is m=3, the transfer functions of the hidden layer and the output layer are tansig and purelin respectively, and the trainlm method is used for training.

[0042] Train the forward cascaded BP neural network on the matlab platform, and after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com