Inter-axle torque global active allocation in-time four-drive system

An active distribution and torque technology, applied in control devices, transportation and packaging, vehicle components, etc., can solve problems such as car trapping, inability to distribute torque, and car instability, achieving rapid response, good driving economy, Guarantee the effect of vehicle power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

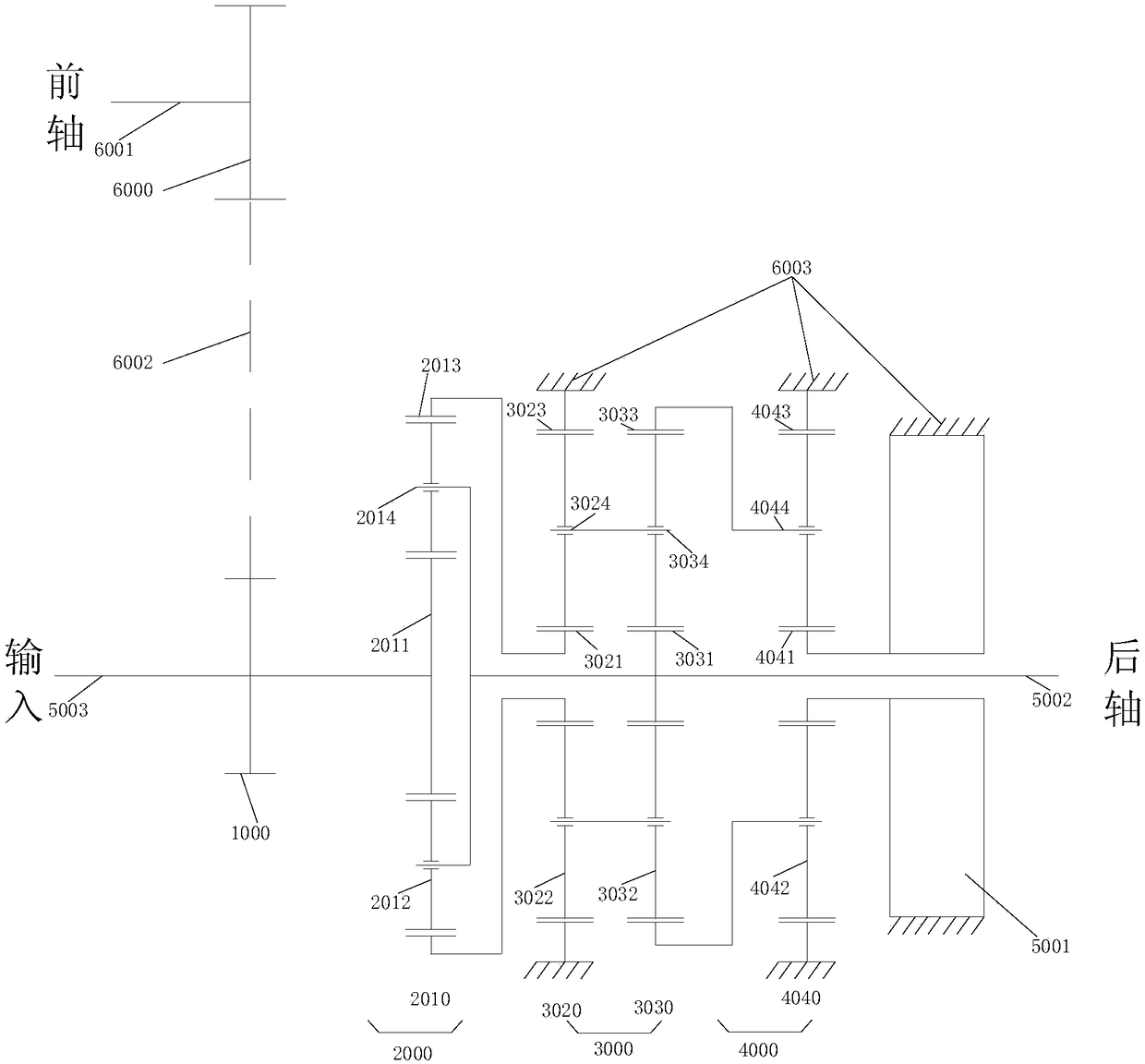

[0079] Such as figure 1 As shown, the present invention provides a timely four-wheel drive system with full-range active distribution of inter-axle torque, which is mainly composed of a central differential 2000, a double planetary row TV coupling mechanism 3000, a TV control motor reduction mechanism 4000 and a TV control motor 5001 .

[0080] The central differential 2000 is located near the power input end and is mainly composed of a first planetary gear train 2010 , including a sun gear 2011 , three planetary gears 2012 evenly distributed along the circumferential direction, an inner ring gear 2013 and a planetary carrier 2014 . Wherein, the center of the planet carrier 2014 and the rear axle 5002 are fixedly connected together by splines. The diameter of the part of the inner ring gear 2013 that extends backward becomes smaller and becomes a hollow stepped hollow shaft. The rear shaft 5002 passes through the hollow shaft from front to back, and a pair of bearings are arr...

Embodiment 2

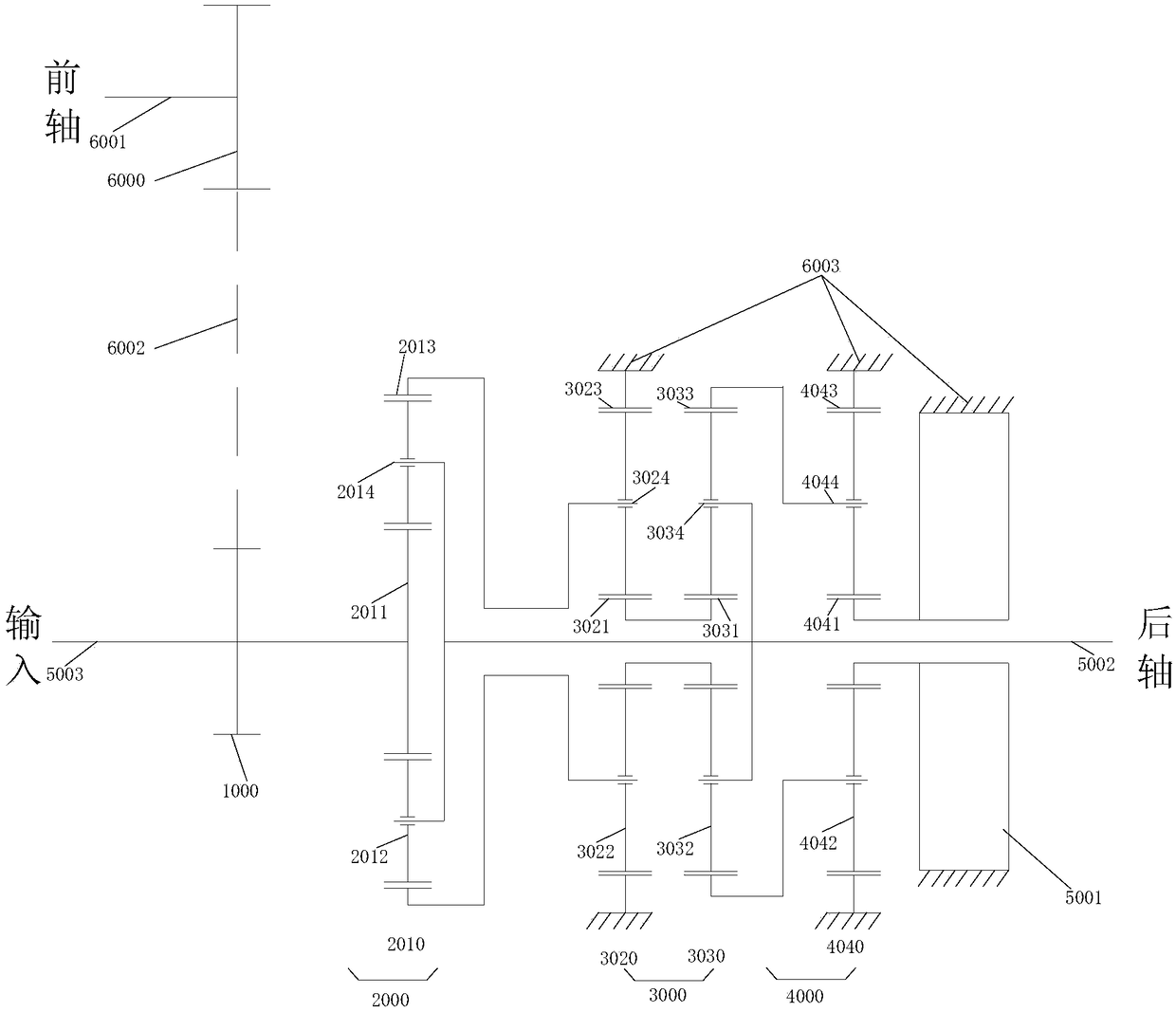

[0088] Such as figure 2 As shown, in this embodiment, a common sun gear type double planetary row TV coupling mechanism 3000 is adopted, that is, the sun gear 3021 of the second planetary gear system 3020 is fixedly connected with the sun gear 3031 of the third planetary gear system 3030, and the sun gear Between the sun gear 3021 and the sun gear 3031 is a hollow hollow shaft, the rear shaft 5002 passes through the hollow shaft from front to back, and a pair of bearings are arranged between the two to reduce the friction and mutual supporting role. The center of the planet carrier 3024 of the second planetary gear train 3020 is fixedly connected with the end of the hollow shaft extending backward of the ring gear 2013 of the first planetary gear train 2010 through splines. The planet carrier 3034 of the third planetary gear train 3030 and the rear axle 5002 extending from the center thereof to the rear are connected together by splines. Structural diagram such as figure ...

Embodiment 3

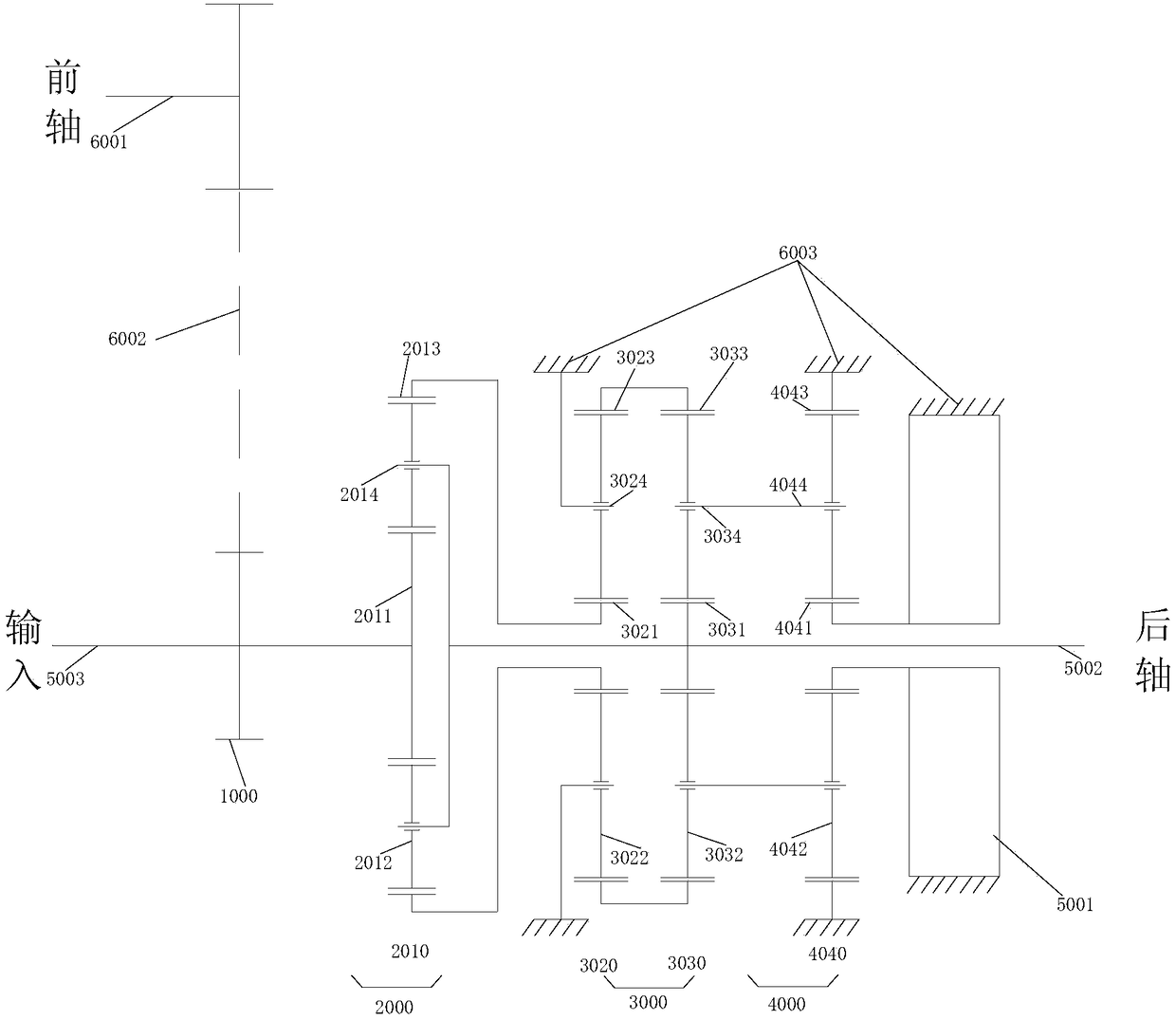

[0090] Such as image 3 As shown, in this embodiment, a common internal ring gear type double planetary row TV coupling mechanism 3000 is adopted, that is, the internal ring gear 3023 of the second planetary gear train 3020 is fixedly connected with the internal gear ring 3033 of the third planetary gear train 3030 , the ring gear 3023 and the ring gear 3033 can be supported by a pair of bearings arranged in the four-wheel drive system housing 6003 . The planet carrier 3024 of the second planetary gear train 3020 is fixedly connected with the housing 6003 of the four-wheel drive system. The planetary carrier 4044 of the fourth planetary gear train 4040 is fixedly connected with the planetary carrier 3034 of the third planetary gear train 3030 . Structural diagram such as image 3 shown.

[0091] The timely four-wheel drive system with global active distribution of inter-axle torque mainly involves four working conditions: the TV control motor 5001 is not activated when driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com