Turning plate type ironing machine

An ironing machine and flap-type technology, which is applied in the field of ironing machines, can solve the problems of poor device practicability, equipment damage, shortening the service life of the equipment, etc., and achieve the effect of improving the service life of the equipment and avoiding dry burning damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

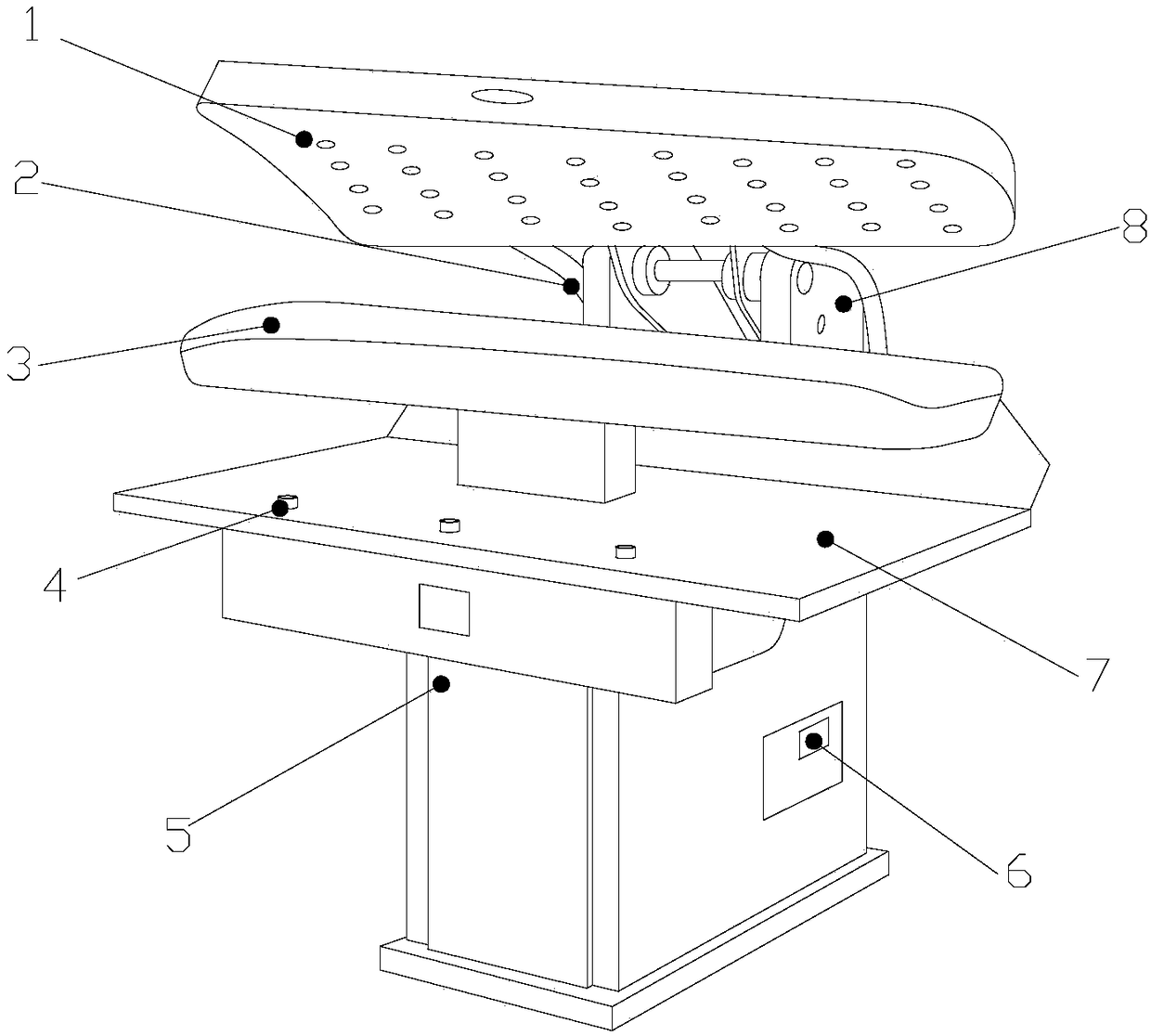

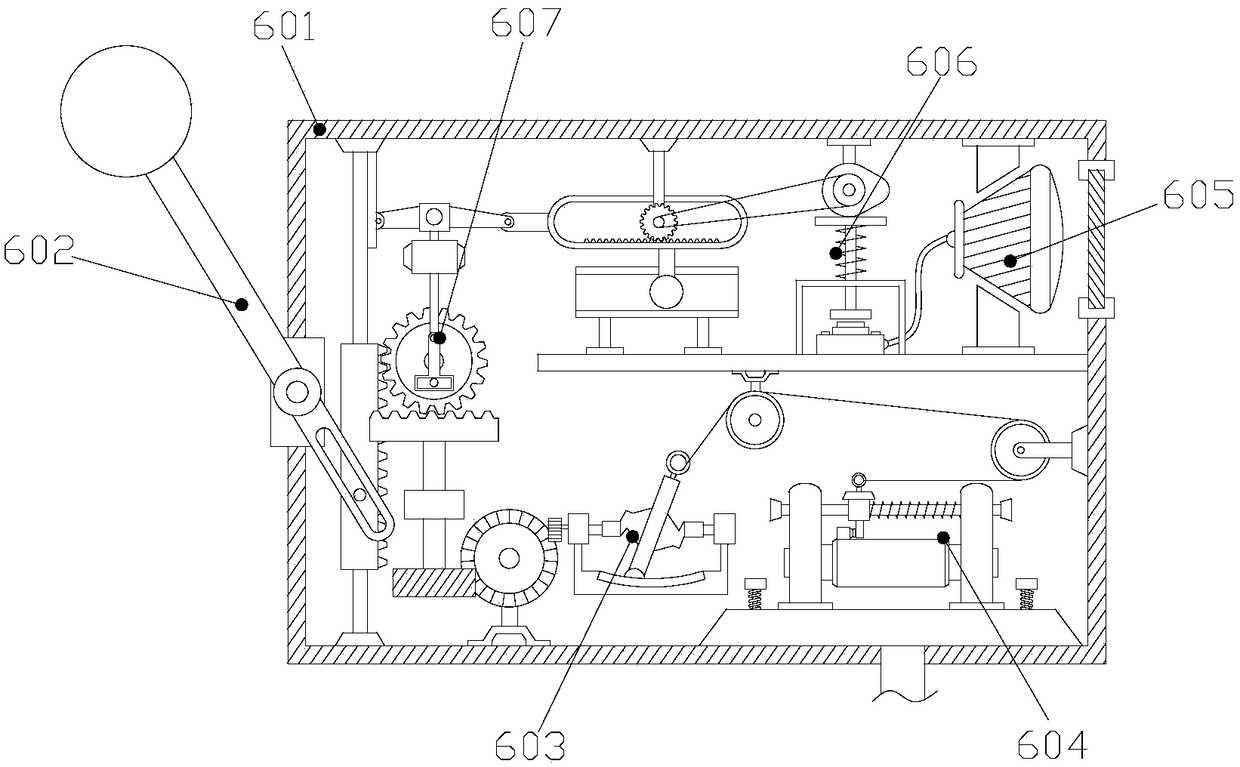

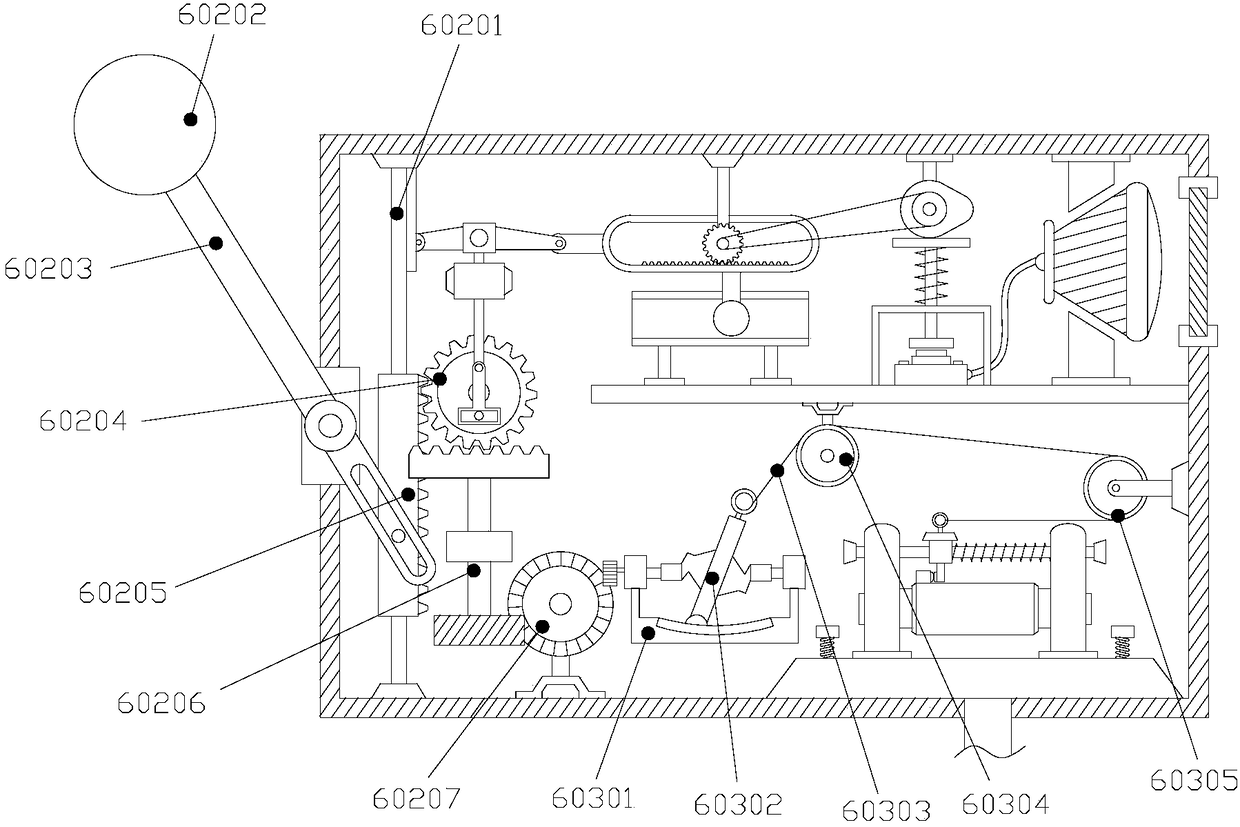

[0021] like Figure 1-Figure 5As shown, the present invention provides a flip ironing machine, the structure of which includes a steam ironing board 1, a steam connecting conduit 2, a clothing lower pressing plate 3, an equipment control panel 4, an equipment support frame 5, a water level alarm 6, and a lower pressing plate support Platform 7, ironing board pole 8, the lower platen support platform 7 is installed on the top of the equipment support frame 5 and is perpendicular to the equipment support frame 5, the water level alarm 6 bolts are fixed on the right side of the equipment support frame 5, the The equipment control panel 4 is installed on the upper surface of the lower platen support platform 7, the garment lower platen 3 is welded on the top of the lower platen support platform 7 and is parallel to the lower platen support platform 7, and the ironing plate support rod 8 is bolted to the lower platen Behind the support platform 7, the steam ironing board 1 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com