Low frequency ripple suppression circuit and control method

A ripple suppression and circuit technology, applied in the control of low-frequency ripple suppression circuits, in the field of low-frequency ripple suppression circuits, can solve the problems of increasing system heat dissipation pressure, increasing system cost and system complexity, and large loss of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

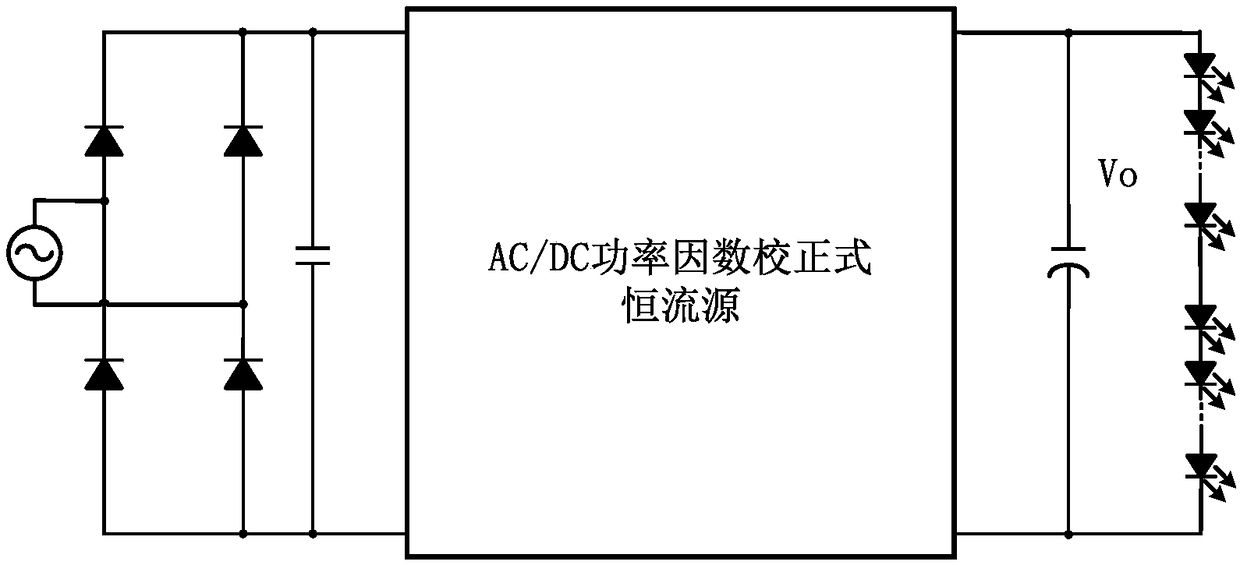

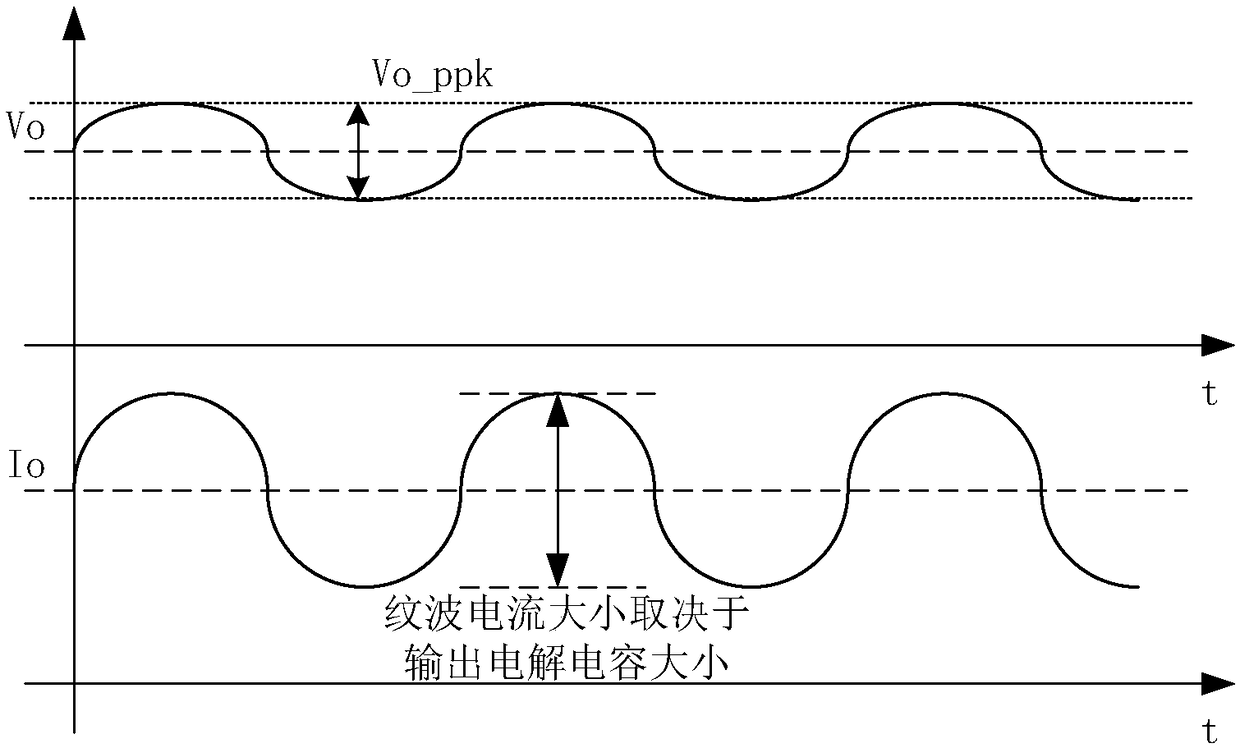

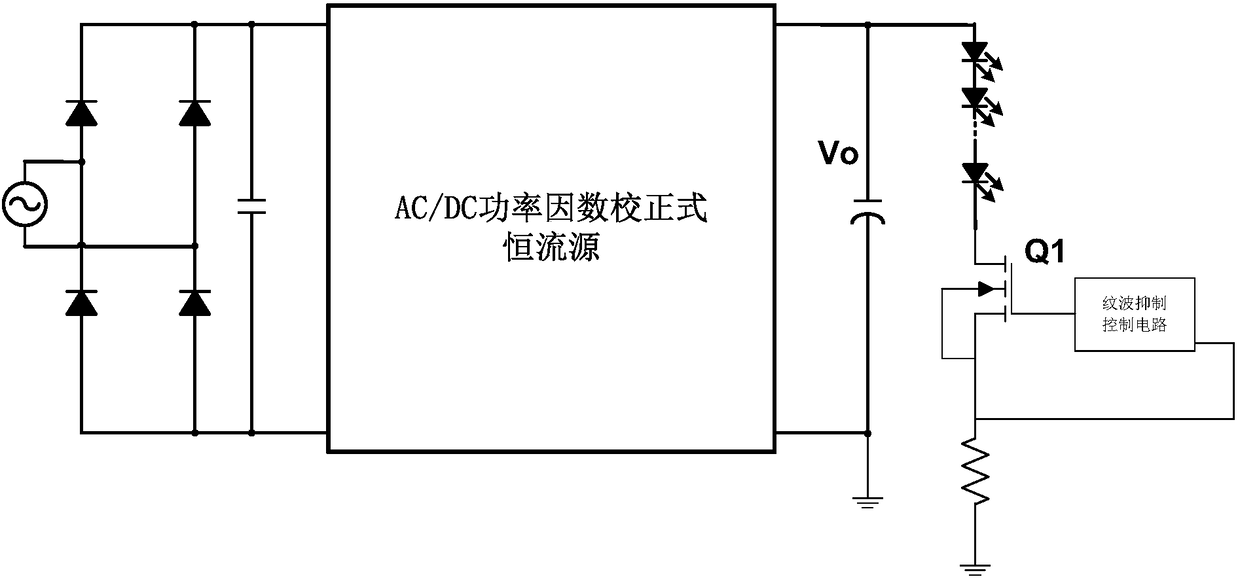

[0100] See Figure 5 , Image 6 The present invention discloses a low-frequency ripple suppression circuit and a control method thereof. The low-frequency ripple suppression circuit includes an energy buffer and a ripple suppression unit, and an AC-DC power factor correction type constant current source circuit. The energy buffer and ripple suppression unit and the LED load are connected in parallel to the constant current source output voltage Vled of the front-stage AC-DC power factor correction constant current source circuit, and the front-stage AC-DC power factor correction constant current source circuit is implemented Power factor correction and constant current output function for the load.

[0101] The AC-DC power factor correction constant current source circuit is a well-known technology in the art, and can be a step-down circuit, a step-up circuit, a flyback circuit, etc. Since it is not the core improvement of the application, it will not be described here.

[0102] Th...

Embodiment 2

[0127] A low-frequency ripple suppression circuit, which includes an energy buffer and a ripple suppression unit, and an AC-DC power factor correction type constant current source circuit;

[0128] The energy buffer and ripple suppression unit and the LED load are connected in parallel to the constant current source output voltage Vled of the front-stage AC-DC power factor correction constant current source circuit, and the front-stage AC-DC power factor correction constant current source circuit is implemented Power factor correction and constant current output function for the load;

[0129] The constant current source output voltage Vled is provided with a second capacitor, and the energy buffer and ripple suppression unit includes a first capacitor Vc1;

[0130] The energy buffer and ripple suppression unit is used to achieve the effect of low ripple of the previous-stage output voltage Vled; when the current-stage AC-DC power factor correction constant current source circuit out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com