Flue-cured tobacco cup capable of removing tobacco tar easily and heating device based on flue-cured tobacco cup

A technology of heating device and flue-cured tobacco cup, which is applied in the field of electronic cigarettes, can solve problems such as uneven heating, affecting taste, and difficult cleaning, and achieves the effects of cleaning and convenient taste, high temperature utilization rate, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

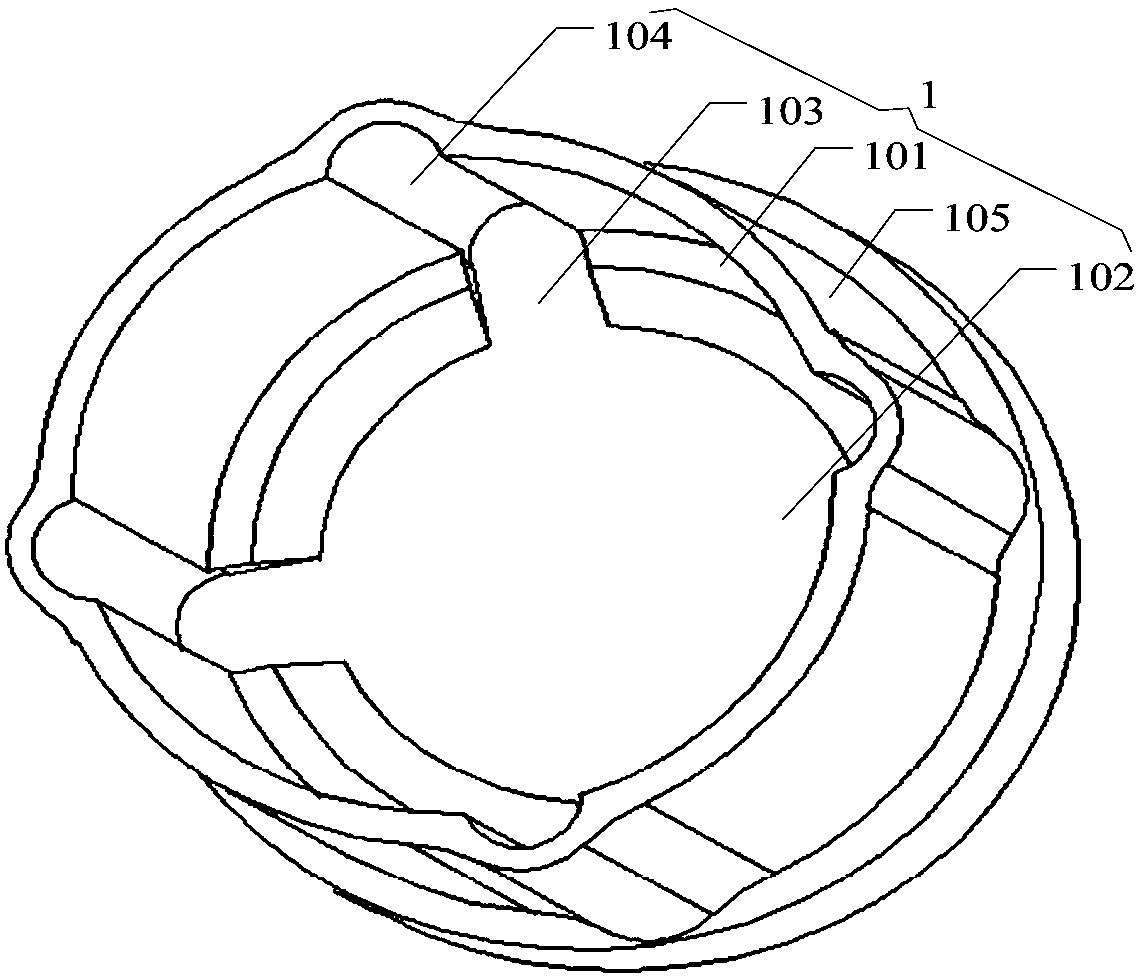

[0052] The cup body 1 is made of metal; each ventilation gap 103 is provided with an air inlet groove 104 that deviates outward from the inner diameter of the cup body on the inner wall of the cup body 1 corresponding to each ventilation gap. 1 through to the ventilation gap 103.

Embodiment 2

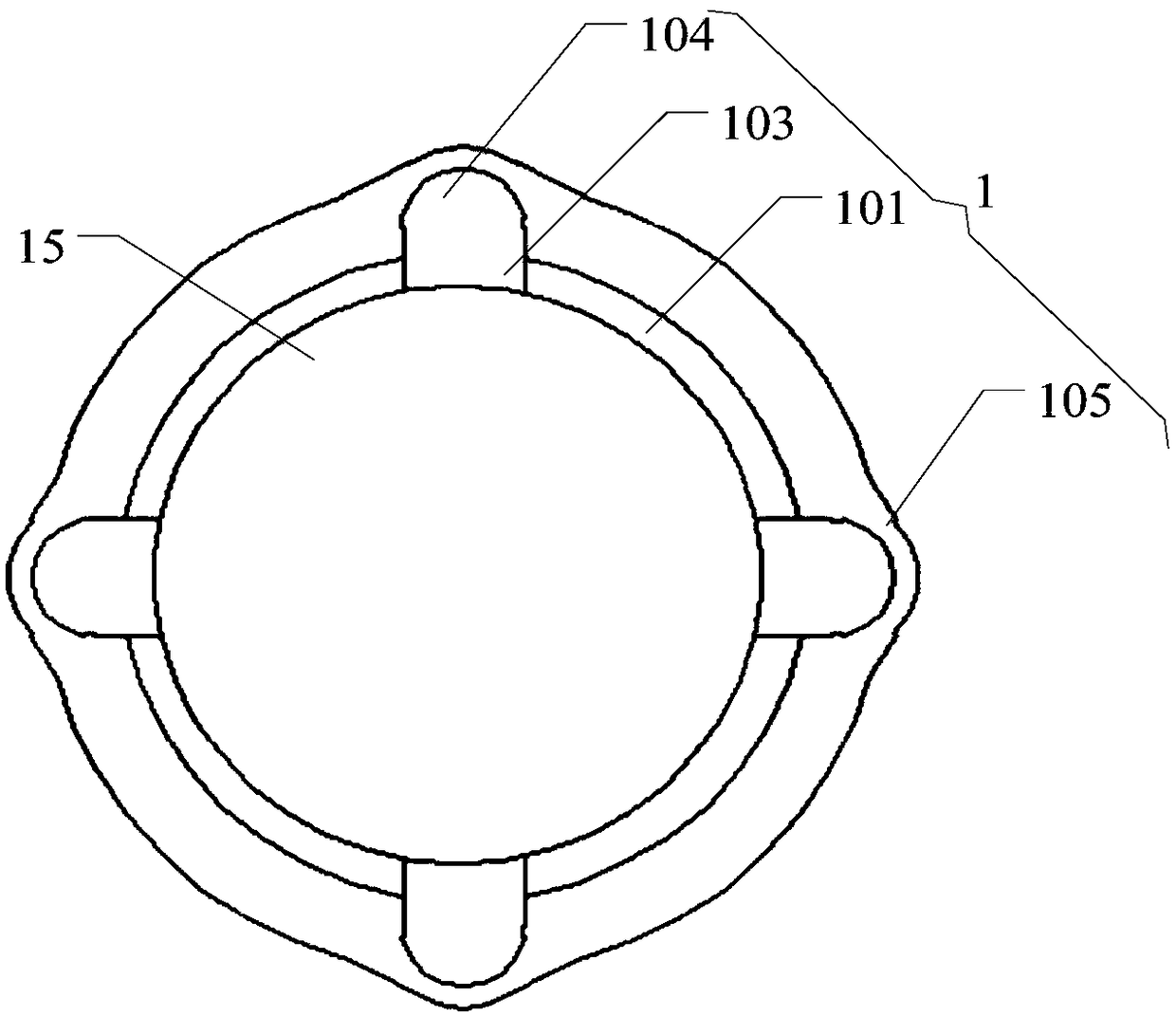

[0054] The main body 1' of the cup is made of ceramic material, and the inner diameter of the main body 1' of the cup is slightly larger than the outer diameter of the cigarette stick 15, so that the outside of the cigarette stick does not completely contact the inner wall of the main body of the cigarette cup.

[0055] In addition, the present invention also provides a heating device based on the flue-cured tobacco cup, which adopts the following technical solutions:

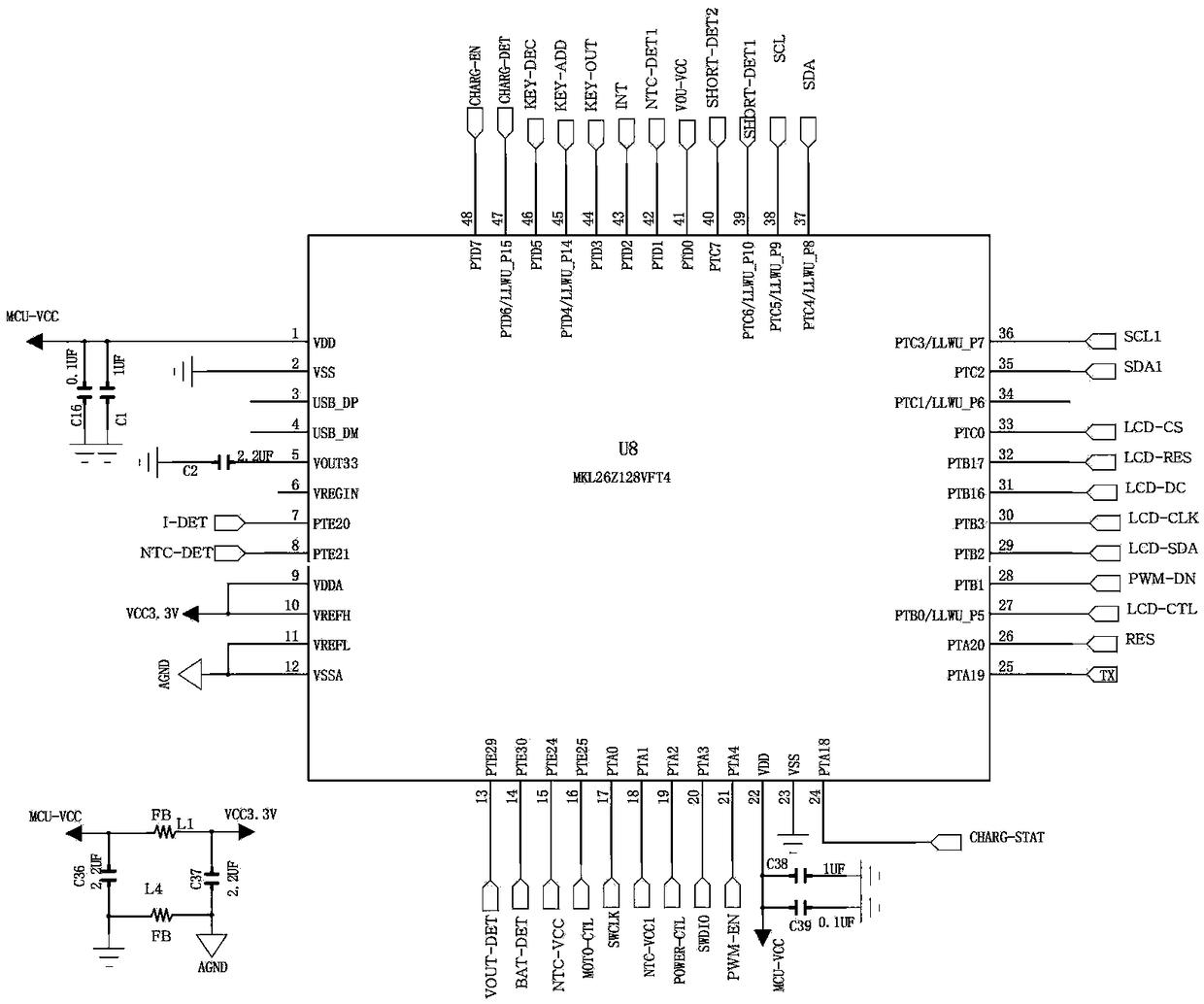

[0056] A heating device based on the flue-cured tobacco cup, comprising the above-mentioned flue-cured tobacco cup, and a battery 2, an MCU control module 3, a button control module 4, a heating furnace control module 5, and a heating furnace 6; the battery 2 is used for power supply, and the MCU controls Module 3 is used to receive the signal of button control module 4 to control the operation of heating furnace control module 5; Feedback to the MCU control module 3 to control the heating furnace 6 to heat the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com