Rapid aging process method of aluminum alloy plate and intelligent control system thereof

An intelligent control system, a technology for aluminum alloy sheets, applied in heat treatment process control, manufacturing tools, furnaces, etc., can solve the problems of materials failing to meet process requirements, unable to grasp the characteristics in real time, and time-consuming, and to speed up the temperature drop efficiency, The effect of shortening the aging processing time and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

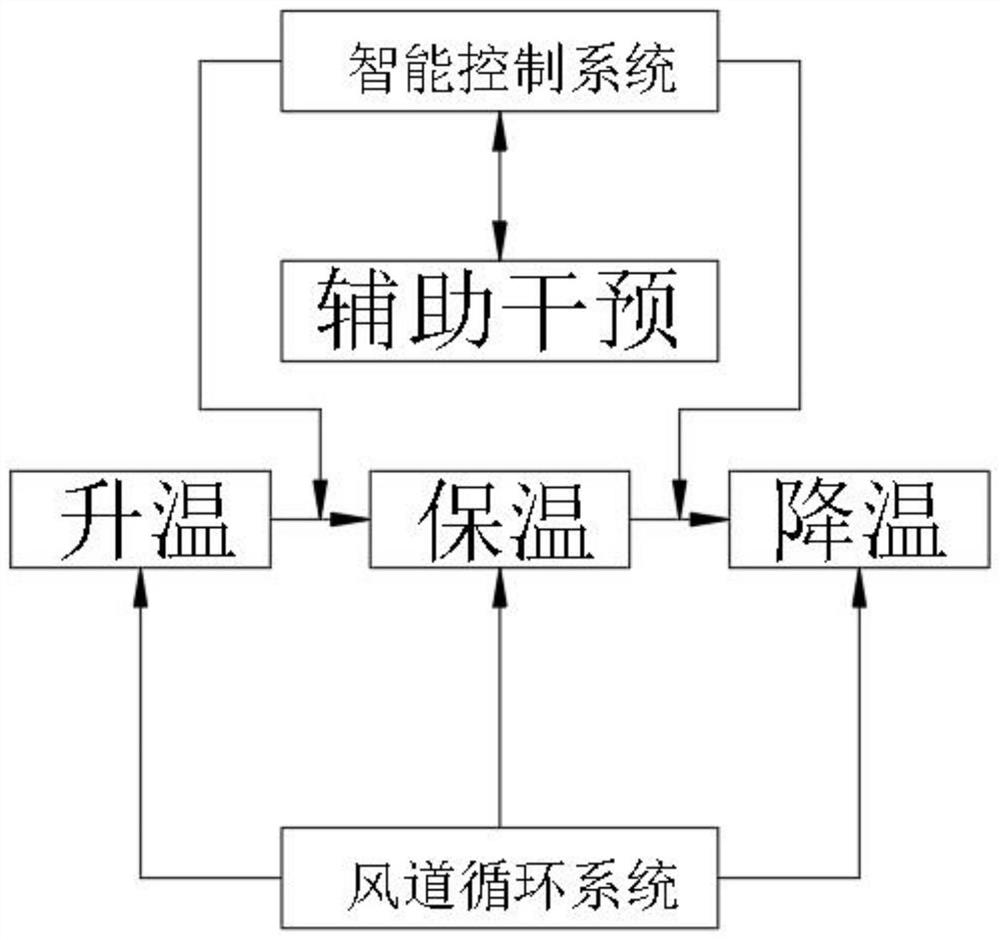

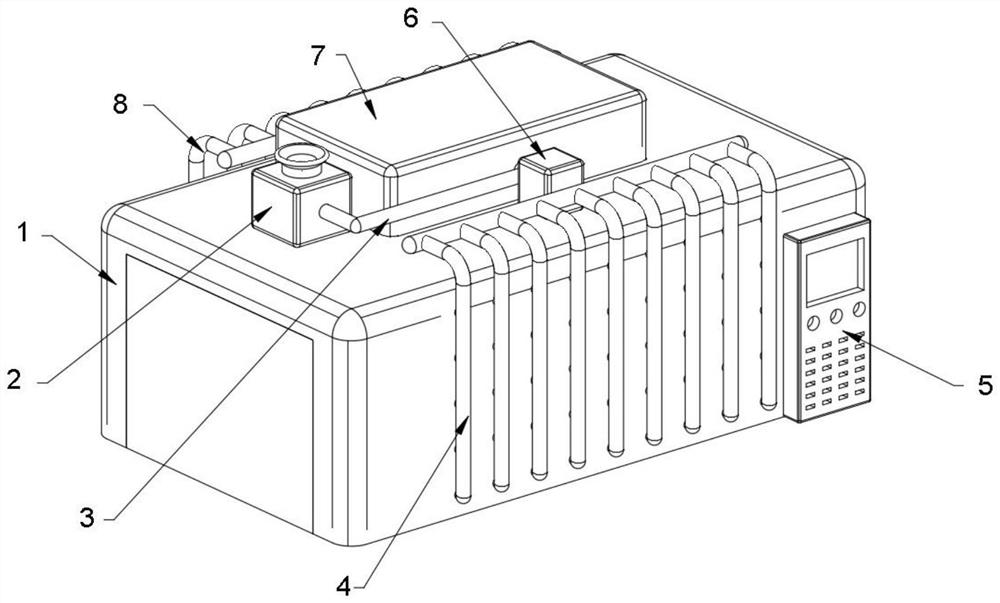

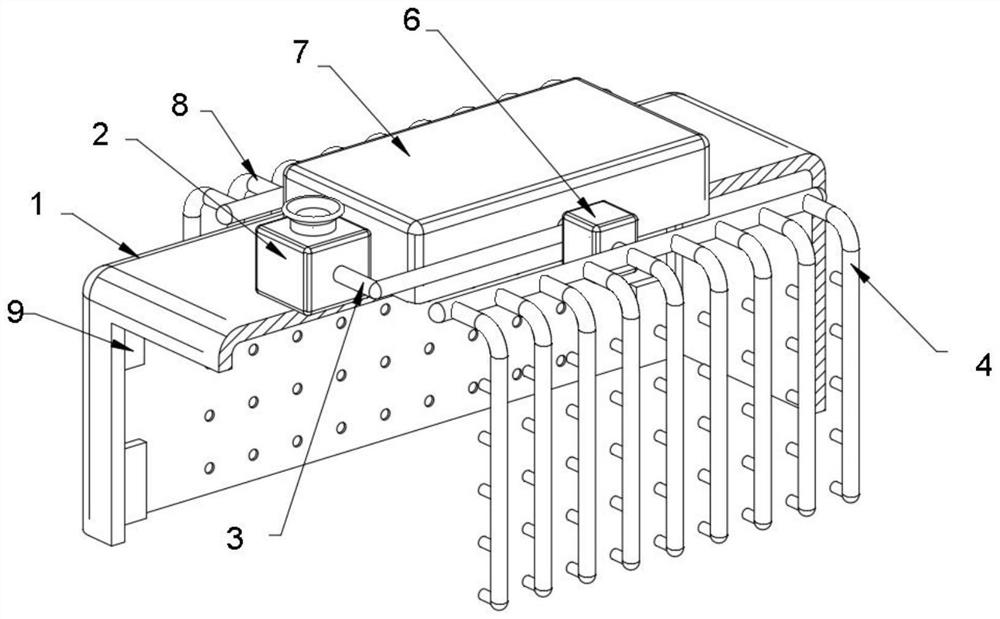

[0038] refer to figure 1 , figure 2 and image 3 , a rapid aging process method for aluminum alloy plates, including a processing equipment body, wherein an electric heating assembly and an air duct circulation assembly are arranged in the processing equipment body, the electric heating assembly is used to heat the aluminum alloy plate, and the air duct circulation assembly is used for Realize the air flow inside the processing equipment body, and the air duct circulation component is used for the temperature flow on the surface of the aluminum alloy plate and the cooling of the aluminum alloy plate;

[0039] Among them, the aging treatment process of the aluminum alloy plate includes: three stages of heating, heat preservation and cooling, and the three stages of heating, heat preservation and cooling all adopt auxiliary intervention methods, and the auxiliary intervention methods are controlled by an intelligent control system. The intelligent control system includes: the...

Embodiment 2

[0044] An intelligent control system for the rapid aging process of aluminum alloy plates. The intelligent control system includes three parts: data preprocessing and input system, data association interaction and practical operation management and control;

[0045] The data preprocessing and input system part includes the following steps:

[0046] S1: Selection of the type of aluminum alloy sheet: select a single type of aluminum alloy sheet and number 1, 2, 3... and then conduct parameter experiments on each numbered sheet. The experimental items are based on the GP area of the aluminum alloy sheet To record and confirm the tensile strength, plasticity and toughness, corrosion resistance, hardness and elongation in aluminum alloy, and record the temperature gradient, time increment period and experimental The volume of the aluminum alloy sheet;

[0047] S2: Based on the preprocessed data in step S1, enter the basic information of each number into the intelligent control s...

Embodiment 3

[0056] The rapid aging process method for aluminum alloy plates includes the following steps:

[0057] X1: Before the heating process of the aluminum alloy plate in the actual processing process, select the information of the corresponding number based on the type of aluminum alloy plate in the actual processing process, and calculate the temperature change in the type of aluminum alloy plate in the actual processing process according to the base again Gradient, time increment cycle;

[0058] X2: Through the intelligent control system, set the tensile strength, plasticity and toughness, corrosion resistance, hardness and elongation data information, and control the start-up of the electric heating component and the air duct circulation component based on the above data information;

[0059] X3: Heat up the aluminum alloy plate through the electric heating component until it reaches the specified maximum critical value, and then automatically jump to the heat preservation or co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com