Patents

Literature

38results about How to "Uneven heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

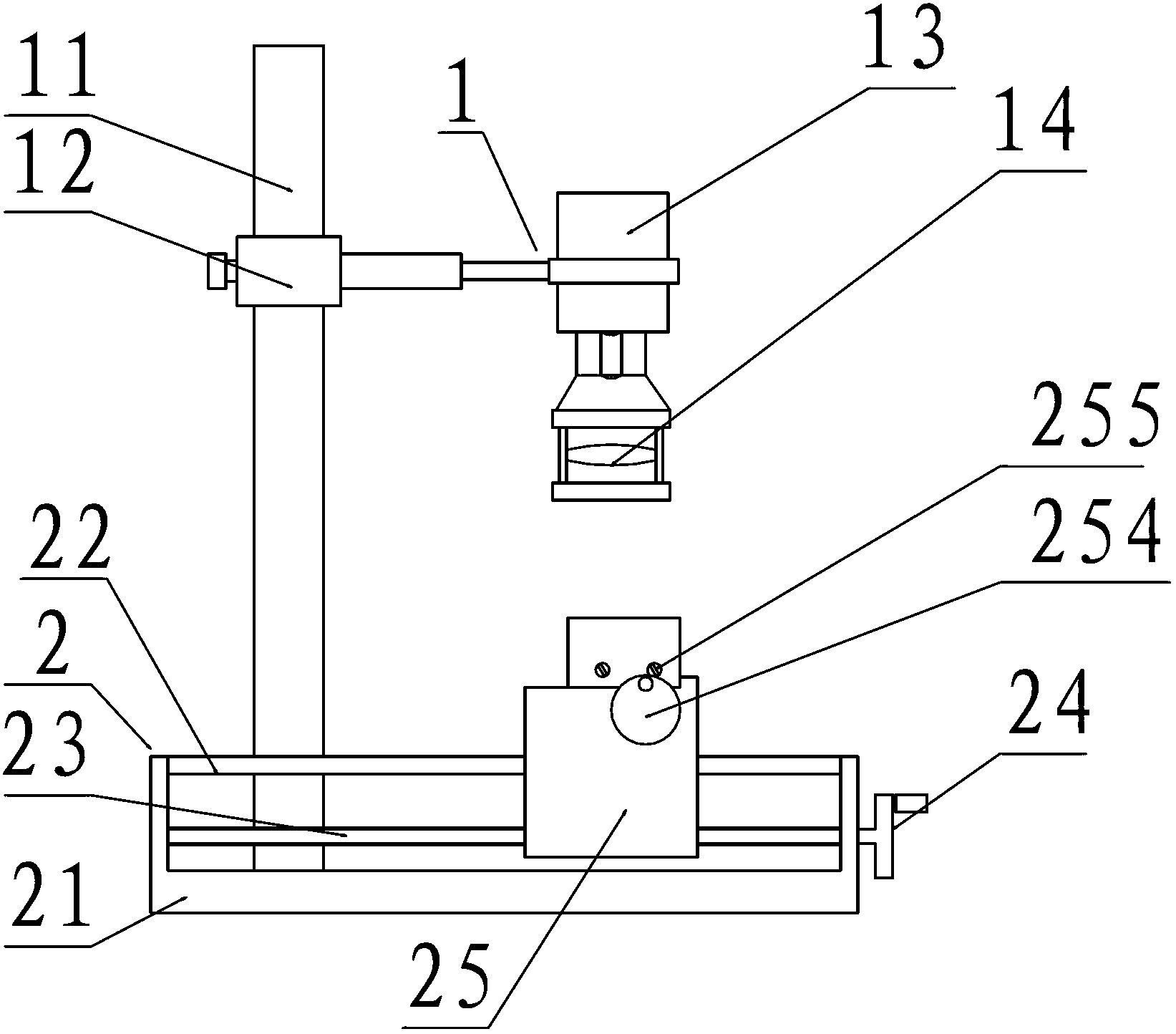

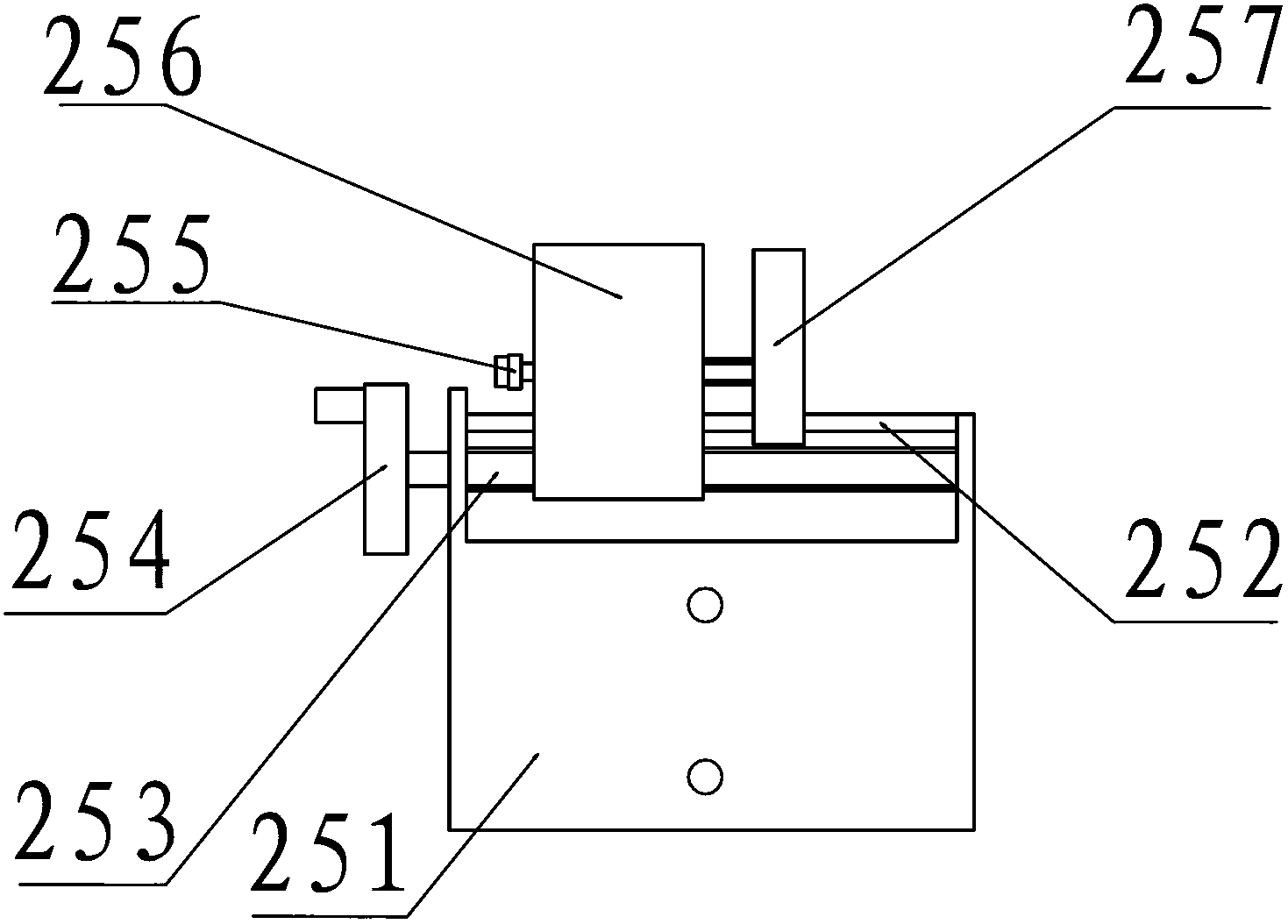

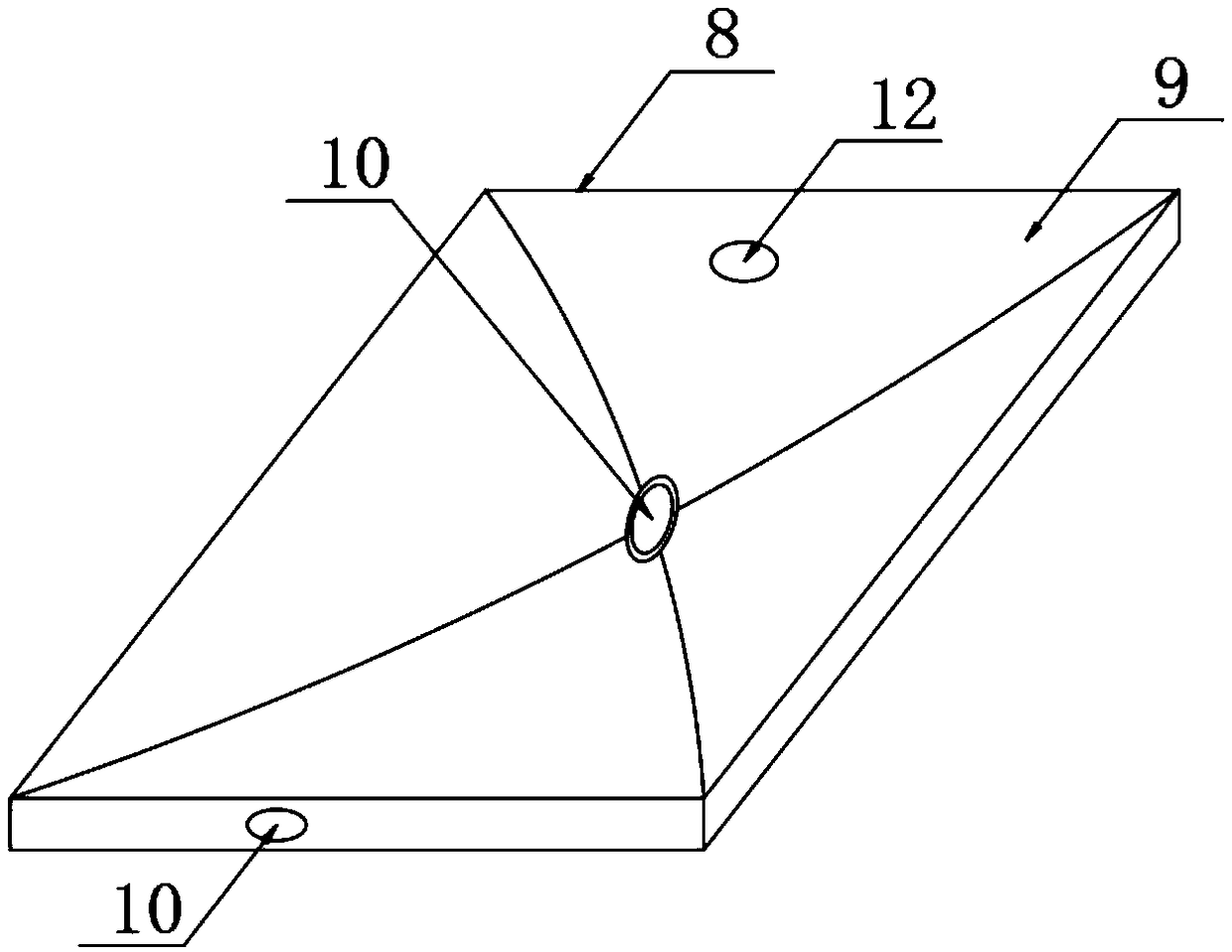

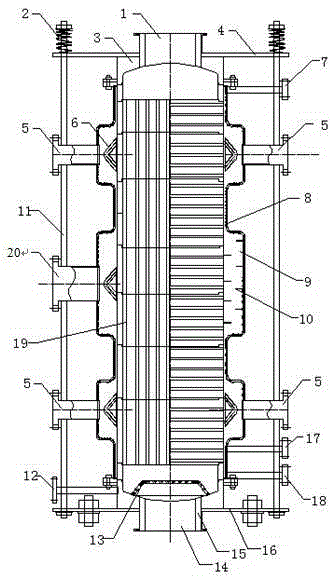

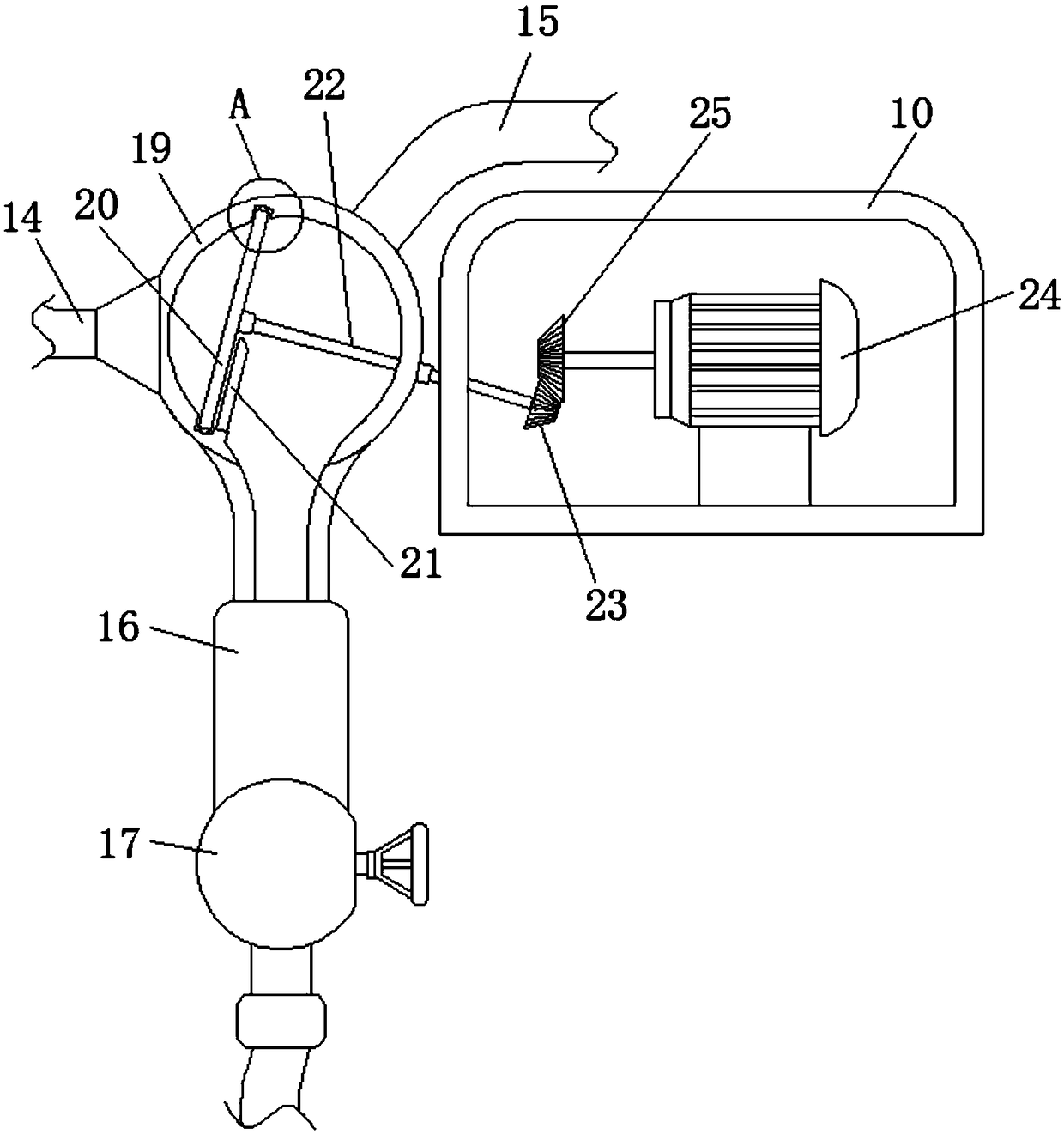

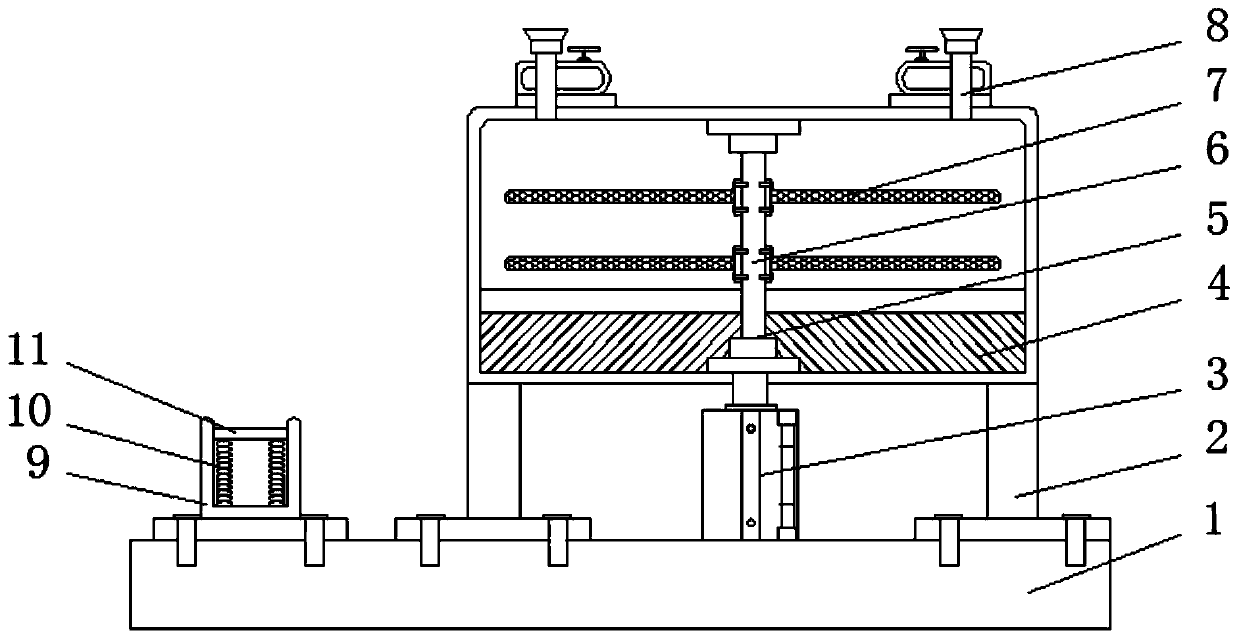

Variable-focus laser-heating thermal fatigue test bed

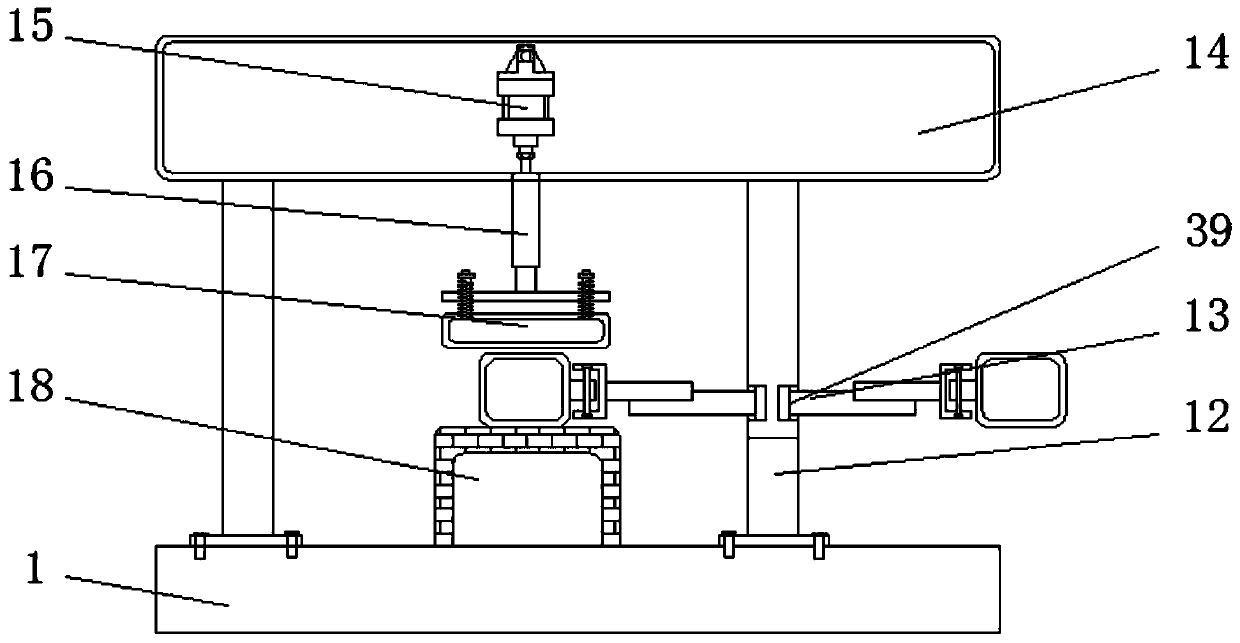

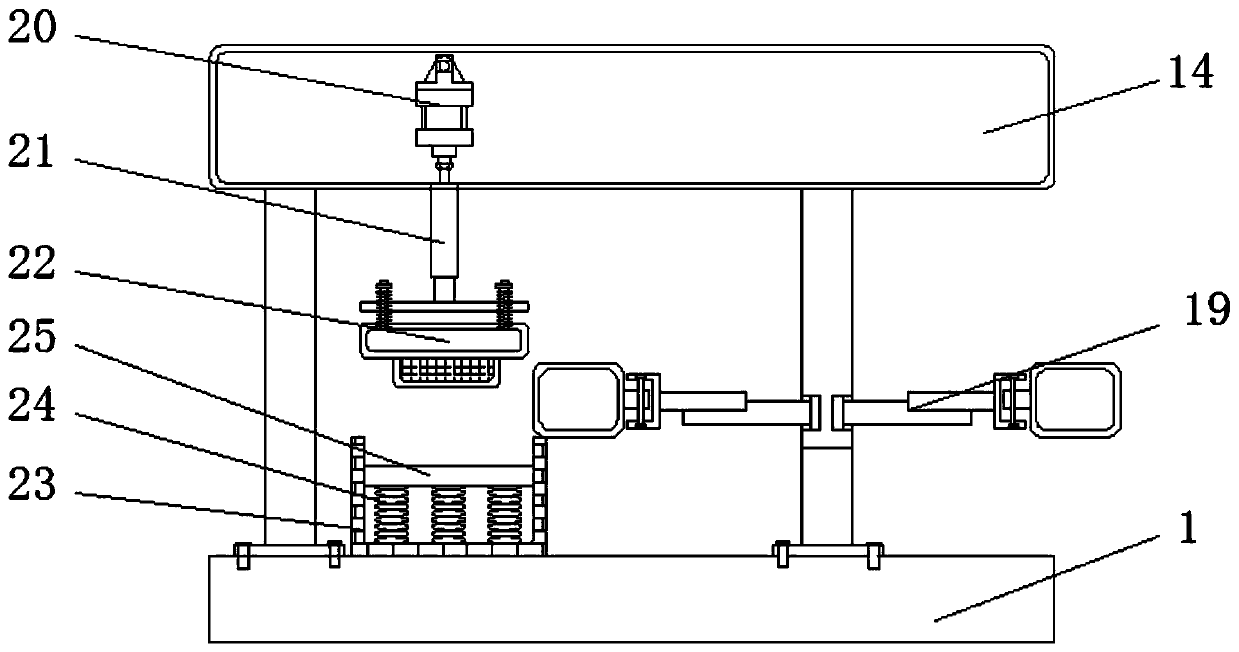

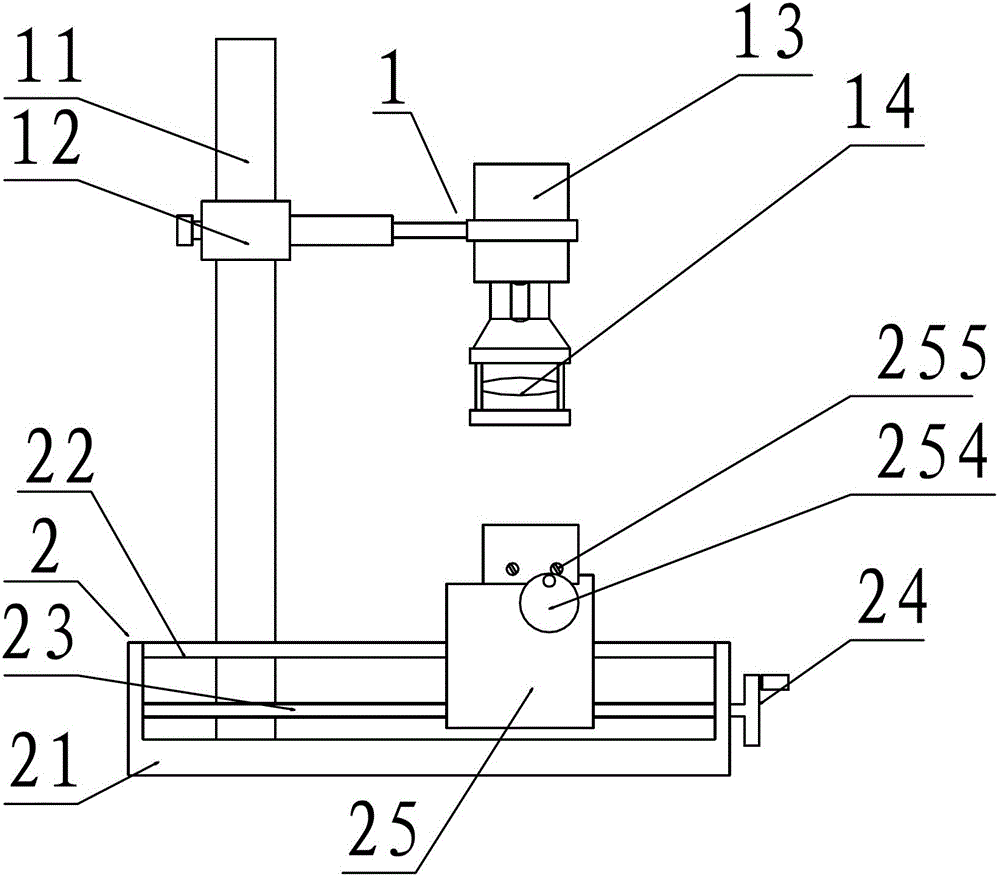

The invention discloses a variable-focus laser-heating thermal fatigue test bed which comprises a variable-focus laser device and a workbench, wherein the variable-focus laser device is installed above the workbench, the variable-focus laser device includes a cross arm which can be adjusted up and down, the cross arm is installed on a stand column, a laser transmitting aperture is fixedly formed in the right end of the cross arm, the lower end of the laser transmitting aperture is connected with a focus lens, and the stand column is fixed on a base body of the workbench. According to the variable-focus laser-heating thermal fatigue test bed with the way adopted, local heating measurement can be conducted according to specimens of different types. The size of a heating range can be controlled by means of adjusting the focus of the lens. Moreover, the specimens can be unequally heated, so that simulation can accord with actual heating conditions, and the thermal fatigue degree of the specimens can be measured out.

Owner:SUZHOU VOCATIONAL UNIV

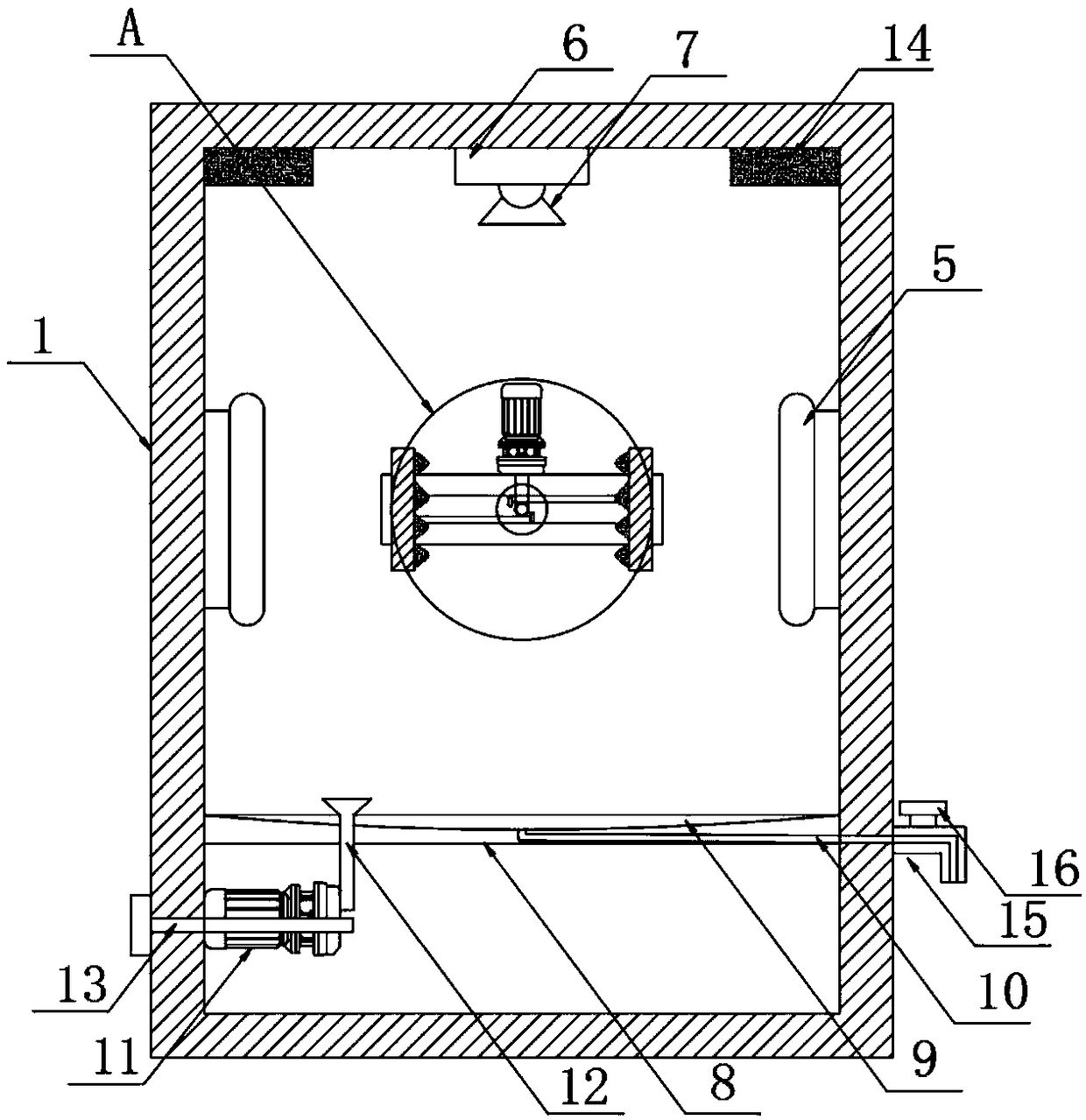

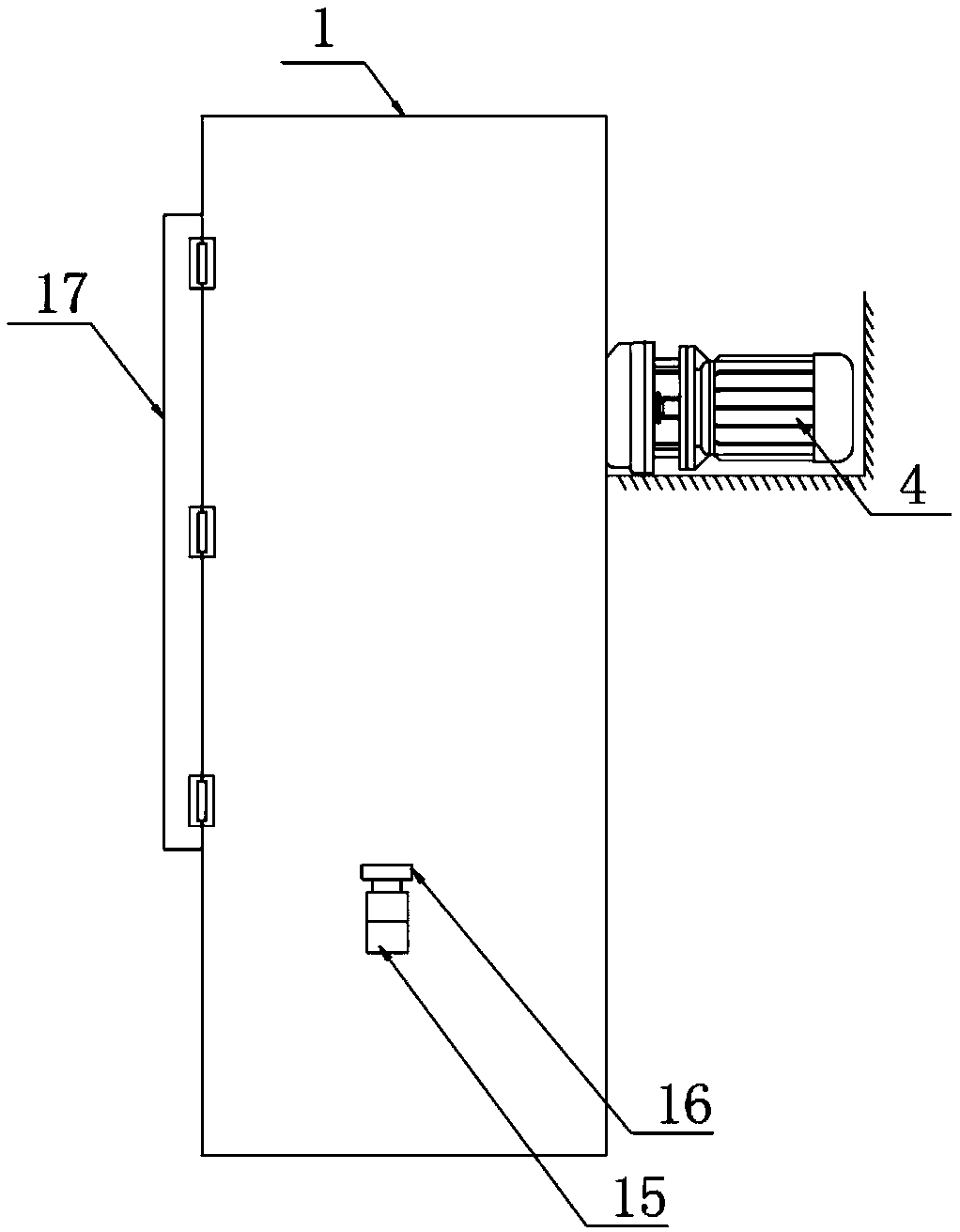

High-temperature carbonization treatment device for bamboo wood toys

The invention discloses a high-temperature carbonization treatment device for bamboo wood toys. The high-temperature carbonization treatment device for the bamboo wood toys comprises a carbonization device body, wherein a clamping device is arranged in the carbonization device body; a rotary shaft is fixedly arranged on one side of the clamping device; one end of the rotary shaft penetrates through one side wall of the carbonization device body and extends to one side of an outer wall of the carbonization device body; a first rotary motor is fixedly arranged on one side of the outer wall of the carbonization device body; an output end of the first rotary motor is connected with an input end of the rotary shaft; and high-temperature heating lamps are arranged on two sides of the clamping device and are fixedly arranged on side walls of an inner cavity of the carbonization device body. According to the high-temperature carbonization treatment device for the bamboo wood toys provided by the invention, when the first rotary motor works, the rotary shaft drives a bamboo wood toy in the clamping device to rotate, so that the occurrence of the phenomenon that the bamboo wood toy is unevenly heated since the end part of the bamboo wood toy is too close to the high-temperature heating lamps is avoided; and when the bamboo wood toy rotates along with the clamping device, the bamboo woodtoy can be evenly heated between the high-temperature heating lamps, so that the processing quality of the bamboo wood toy is improved.

Owner:JMINDUSTRIES GRP

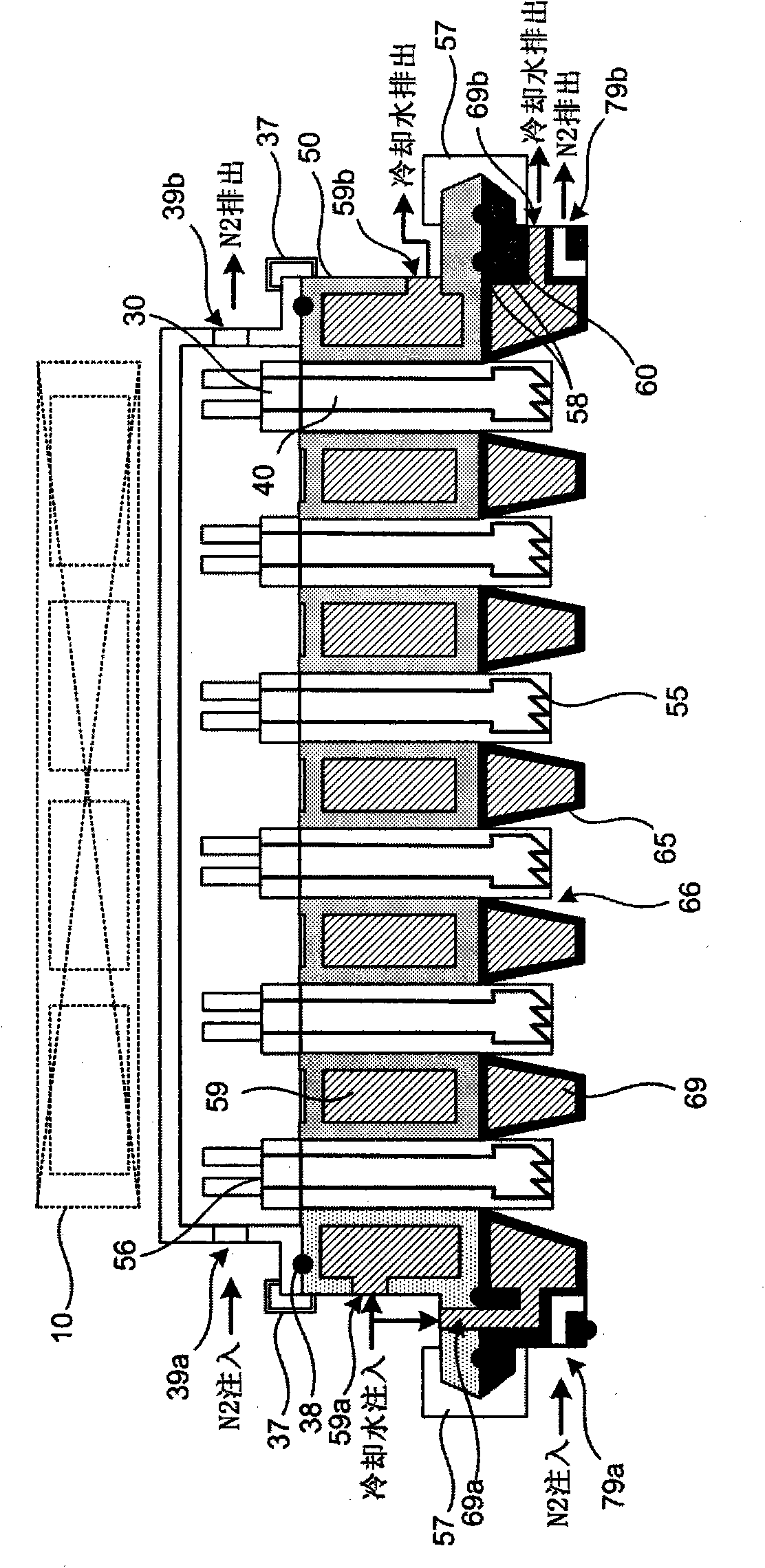

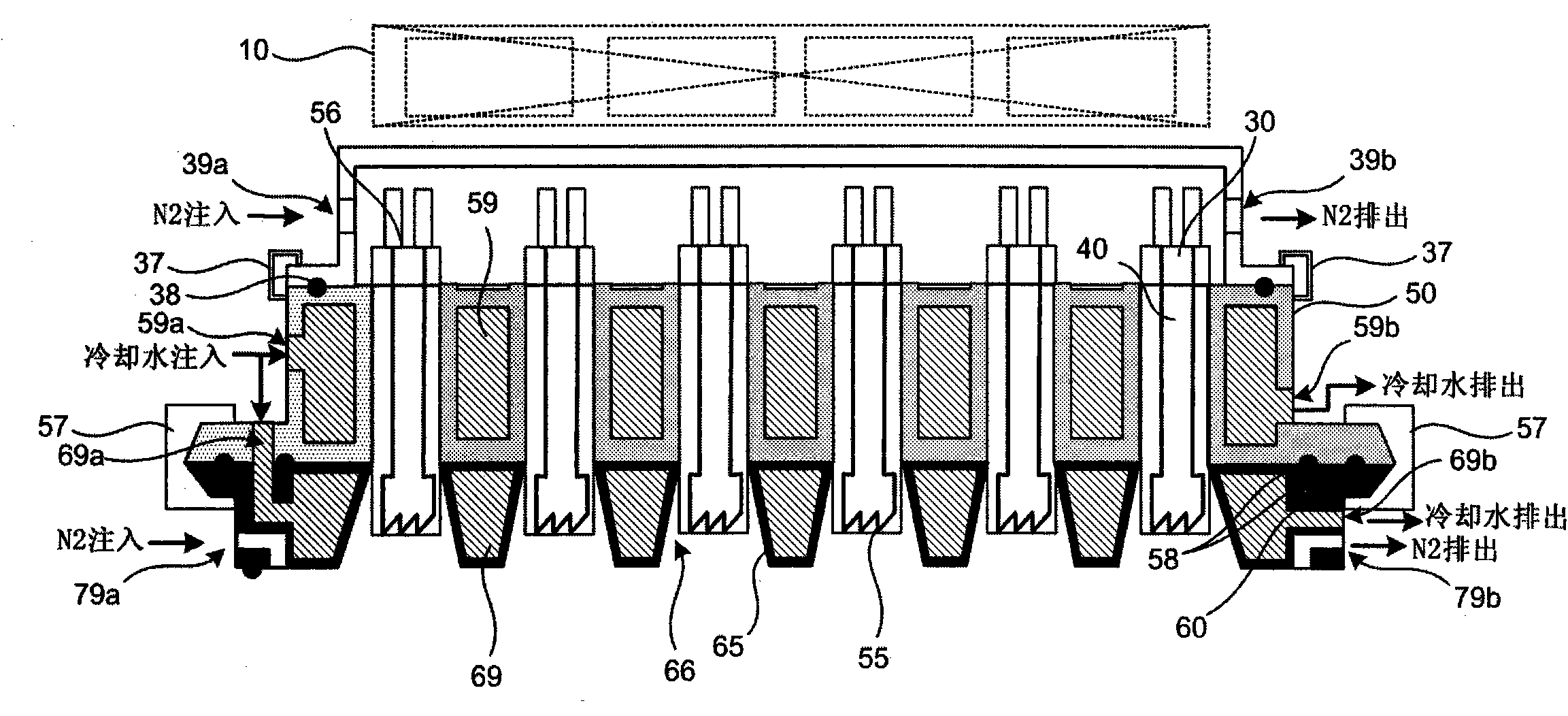

Heater block of rapid thermal process apparatus

InactiveCN101919304AAvoid damageUneven heatingHeater elementsSemiconductor/solid-state device manufacturingWater flowEngineering

Disclosed is a separation type heater block of a rapid thermal processing apparatus, including a lamp housing formed in a plate shape, and provided with a plurality of lamp insertion holes, into which heating lamps are respectively inserted; a socket housing, into which sockets of the heating lamps are inserted, separably covered on the lamp housing; and a reflector housing provided with light emission holes at positions corresponding to the lamp insertion holes, separably installed under the lamp housing such that lower ends of the heating lamps are respectively inserted into the light emission holes, side walls of the light emission holes serving as barriers, wherein a cooling water channel, through which cooling water flows, is formed through the side walls of the light emission holes of the reflector housing.

Owner:AP SYST INC

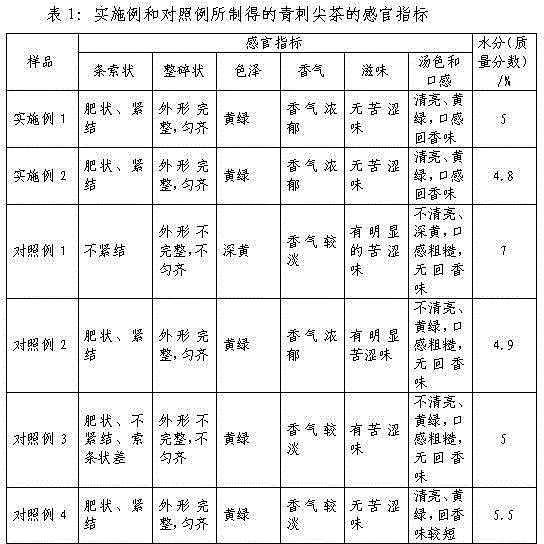

Prinsepia utilis tea preparing method

The present invention discloses a prinsepia utilis tea preparing method, and belongs to the technical field of agricultural product processing. The preparing method comprises the following steps in order: A, harvesting and collecting: fresh prinsepia utilis tender leaves are collected; B, hot steaming: the prinsepia utilis tender leaves after being sun-dried are wrapped with a damp cloth, the wrapped tea leaves are placed in a heating tank prepared by using alnus cremastogyne material and hot-steamed in a heating manner by using water vapor to heat the bottom part of the heating tank for 30 minutes; C, spreading and air-drying: the hot-steamed prinsepia utilis leaves are cooled to a temperature of 10-15 DEG C; D, rolling: the cooled prinsepia utilis leaves are put on a taxus chinensis wood board and rolled using palms according to the same direction for 20-30 min; E, frying to dehydrate: the prinsepia utilis leaves is fried into a moisture content of less than 5%; F, second spreading and air-drying: the dried prinsepia utilis leaves are cooled to a temperature of 25-30 DEG C; G, fragrance improving: the temperature of the cooled prinsepia utilis leaves is controlled at 160-180 DEG C and the fragrance improving is conducted for 10-20 minutes; and H: packaging. The prinsepia utilis tea preparing method can effectively remove the bitter taste of the prinsepia utilis tea, improve the cable and stripped appearance and fragrance of the prinsepia utilis tea, and enable the prinsepia utilis tea to be better in mouthfeel when the prinsepia utilis tea is drunk.

Owner:云龙县大栗树大山头茶厂

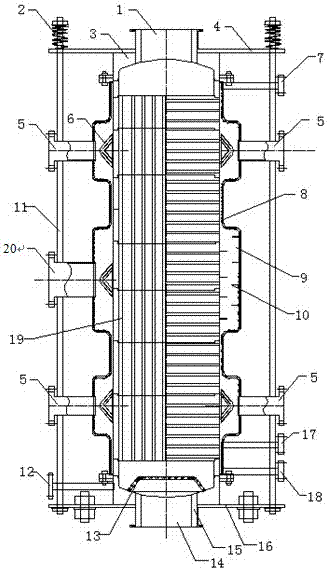

Graphite evaporator and automatic control system thereof

ActiveCN105396304AIncrease profitImprove heat transfer efficiencyEvaporationSimultaneous control of multiple variablesAutomatic controlEngineering

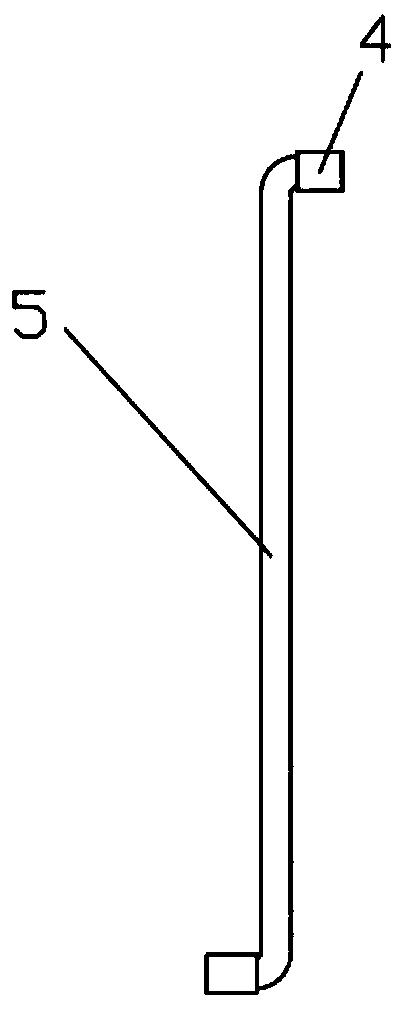

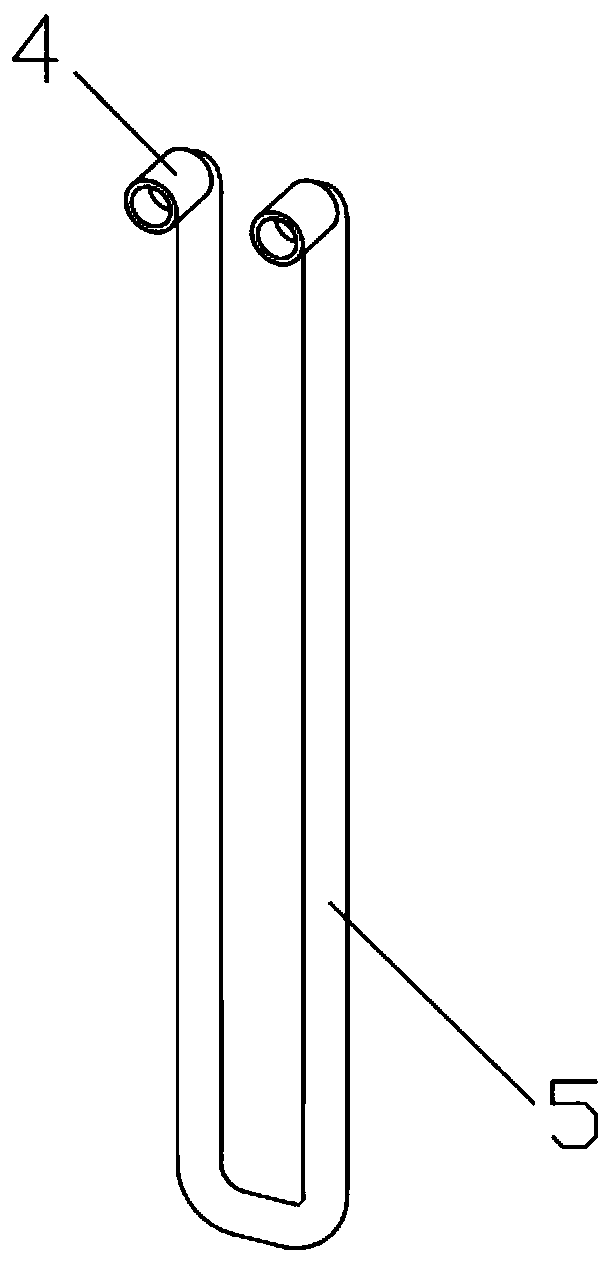

The invention provides a graphite evaporator. The graphite evaporator comprises a housing, a waveform heat insulating layer is spread on an inner wall of the housing, a corrosion preventing composite layer is spread on an outer wall of the housing, and the housing is made from stainless steel; the upper part, the middle part and the lower part of the housing are separately provided with a loop of steam distributor, sides of each of the steam distributors at the upper part and the lower part of the housing are provided with steam inlets, a steam inlet passage is arranged at one side of the steam distributor in the middle part of the housing, automatic control systems are connected to the steam inlets, and a steam outlet is arranged above one side of the steam inlet at the upper part of the housing; several U-shaped grooves and lateral through holes are arranged at the outside of graphite heat exchange blocks, and places between every two layers of the graphite heat exchange blocks are sealed with fluororubber. The graphite evaporator has the advantages of improved steam utilization rate, enhanced corrosion resistance, high temperature resistance and high pressure resistance, prolonged service life, and excellent performance; automatic control is realized at the same time. The invention also comprises an automatic control system for controlling the graphite heat exchanger.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

High-magnetic performance NdFeB magnet capable of cyclically utilizing waste material and fabrication method of NdFeB magnet

ActiveCN108922713AUniform compositionUniform qualityInductances/transformers/magnets manufactureMagnetic materialsNeodymium iron boronWaste material

The invention relates to a fabrication method of a magnet, in particular to a high-magnetic performance NdFeB magnet capable of cyclically utilizing a waste material and a fabrication method of the NdFeB magnet. By the NdFeB magnet, the technical problems that each constituent of the NdFeB magnet in the prior art is not uniform in distribution during sintering and a blank is also not uniform in heating during sintering to cause that the produced NdFeB magnet is not uniform in magnetic force distribution and relatively low in magnetic performance are solved. The high-magnetic performance NdFeBmagnet is fabricated according to the steps of putting each constituent powder into a vacuum rapid-hardening furnace for casting, sending the casting into a hydrogen decropitation furnace for hydrogendecropitation, sending hydrogen broken powder into an automatic magnetic field press machine, performing press formation and isostatic pressing under an orientated magnetic field with magnetic fieldintensity being 1.4-2.0T, placing the formed blank in a vacuum sintering furnace for three-segment sintering, placing the sintered blank in a grinding machine for double-sided grinding, performing line cutting after light blank verification, and performing formation, black wafer verification and finished product verification.

Owner:杭州双成磁业有限公司

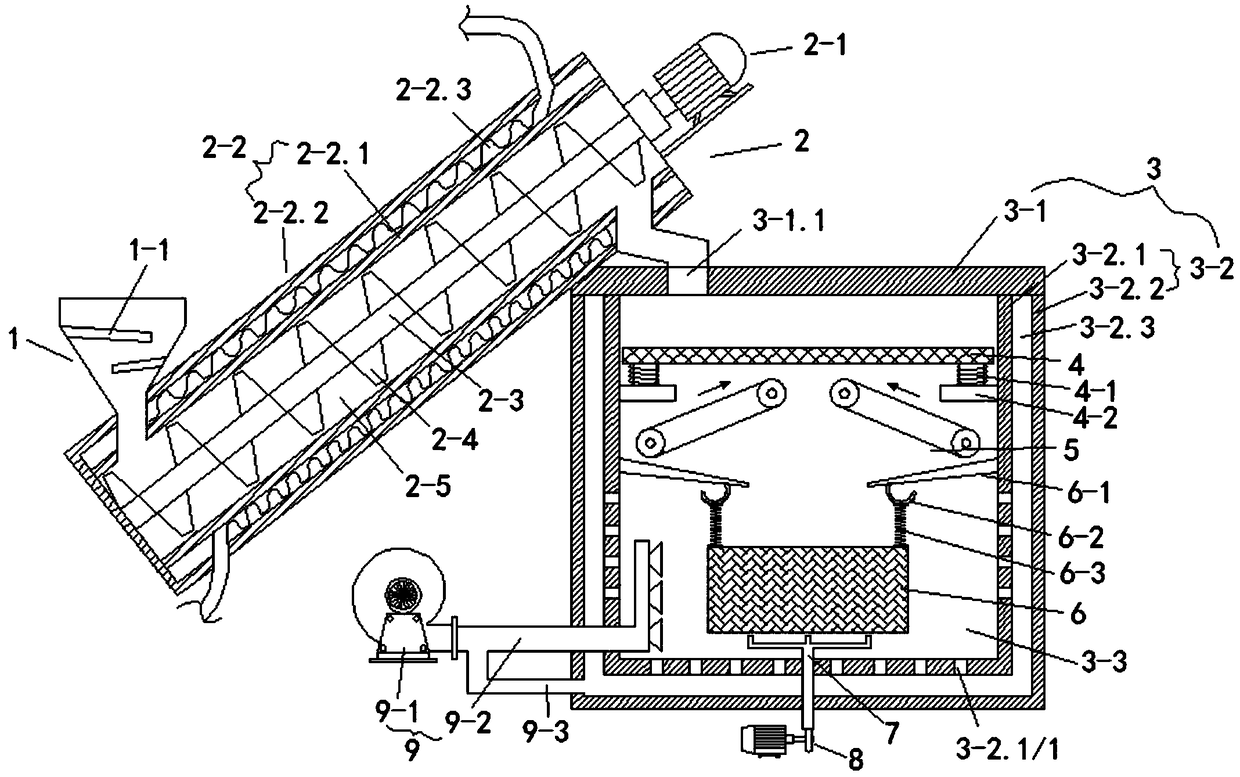

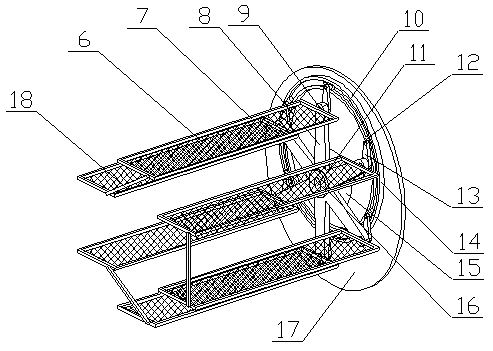

Traditional Chinese medicine drying equipment

InactiveCN109442940AAvoid accumulationUneven heatingDrying gas arrangementsDrying chambers/containersEngineeringMaterials processing

The invention discloses traditional Chinese medicine drying equipment, and relates to the technical field of traditional Chinese medicinal material processing equipment. The traditional Chinese medicine drying equipment comprises a drying box and a hot air supply system communicating with the drying box, wherein the drying box comprises a box cover and a box body which are connected in a sealing manner, a feeding port is formed in the box cover, a secondary drying cavity is defined by the box cover and the box body, the traditional Chinese medicine drying equipment further comprises a materialtransferring and drying assembly, wherein a material discharging port of the material transferring and drying assembly communicates with the feeding port, a filtering net is arranged at the upper part of the secondary drying cavity, a plurality of conveying belts which are uniformly distributed around the center of the filtering net are arranged below the filtering net, the conveying direction ofthe plurality of conveying belts points to the center of the filtering net, and a material receiving and pounding assembly used for containing materials and stirring the materials is arranged below the plurality of conveying belts. According to the traditional Chinese medicine drying equipment, the structure is simple, the two-stage drying treatment is carried out, traditional Chinese medicinal materials are continuously stirred during drying, the drying efficiency is improved, and the drying effect is optimized.

Owner:刘永华

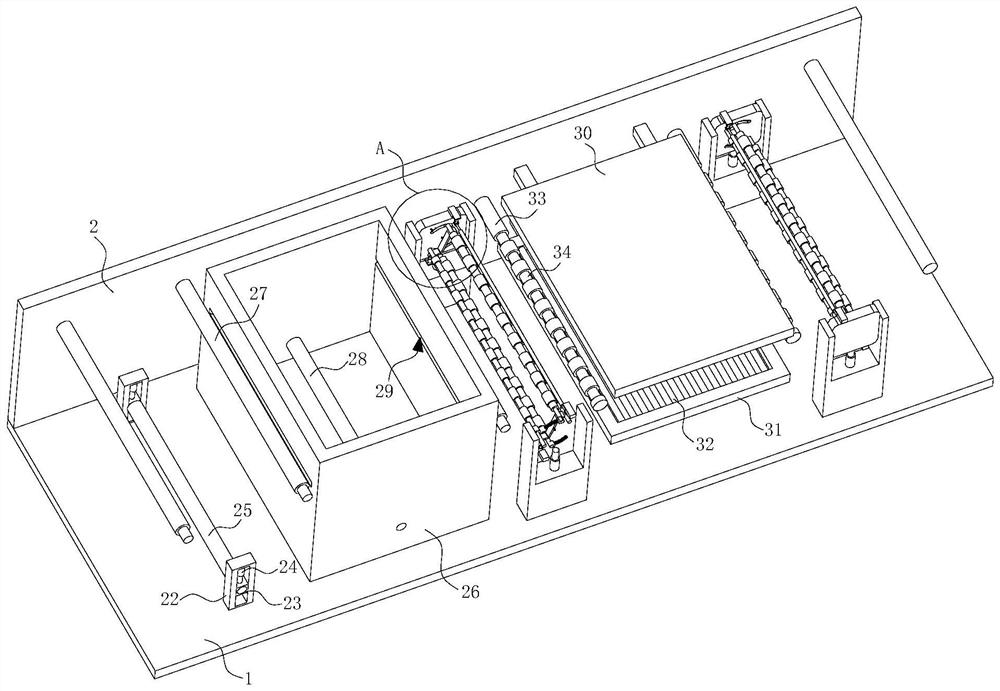

Dyeing and drying device for chemical fiber production

InactiveCN111945325AQuickly tenseAvoid bendingLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removalFiberMechanical engineering

The invention discloses a dyeing and drying device for chemical fiber production. The device comprises a bottom plate, wherein a mounting plate is fixedly connected to the left side of the top surfaceof the bottom plate, a feeding mechanism is arranged at the front part of the right side wall of the mounting plate, a dyeing device is fixedly arranged at the top of the bottom plate, a drying device is fixedly arranged on the right side wall of the mounting plate, a collecting roller is rotatably connected to the rear side of the right side wall of the mounting plate, and two tensioning mechanisms which are symmetrically arranged about front and rear sides of the drying device are arranged at the top of the bottom plate. Through the arrangement of the above-mentioned structure, chemical fibers on a drying mechanism can be rapidly tightened when the chemical fibers are loosened due to errors in a chemical fiber drying process, the situation that the chemical fibers are bent in the dryingmechanism, and consequently the chemical fibers are heated unevenly can be avoided, damage to the chemical fibers caused by too high drying temperature of the chemical fibers is avoided, and waste ofthe chemical fibers can be avoided.

Owner:黄红志

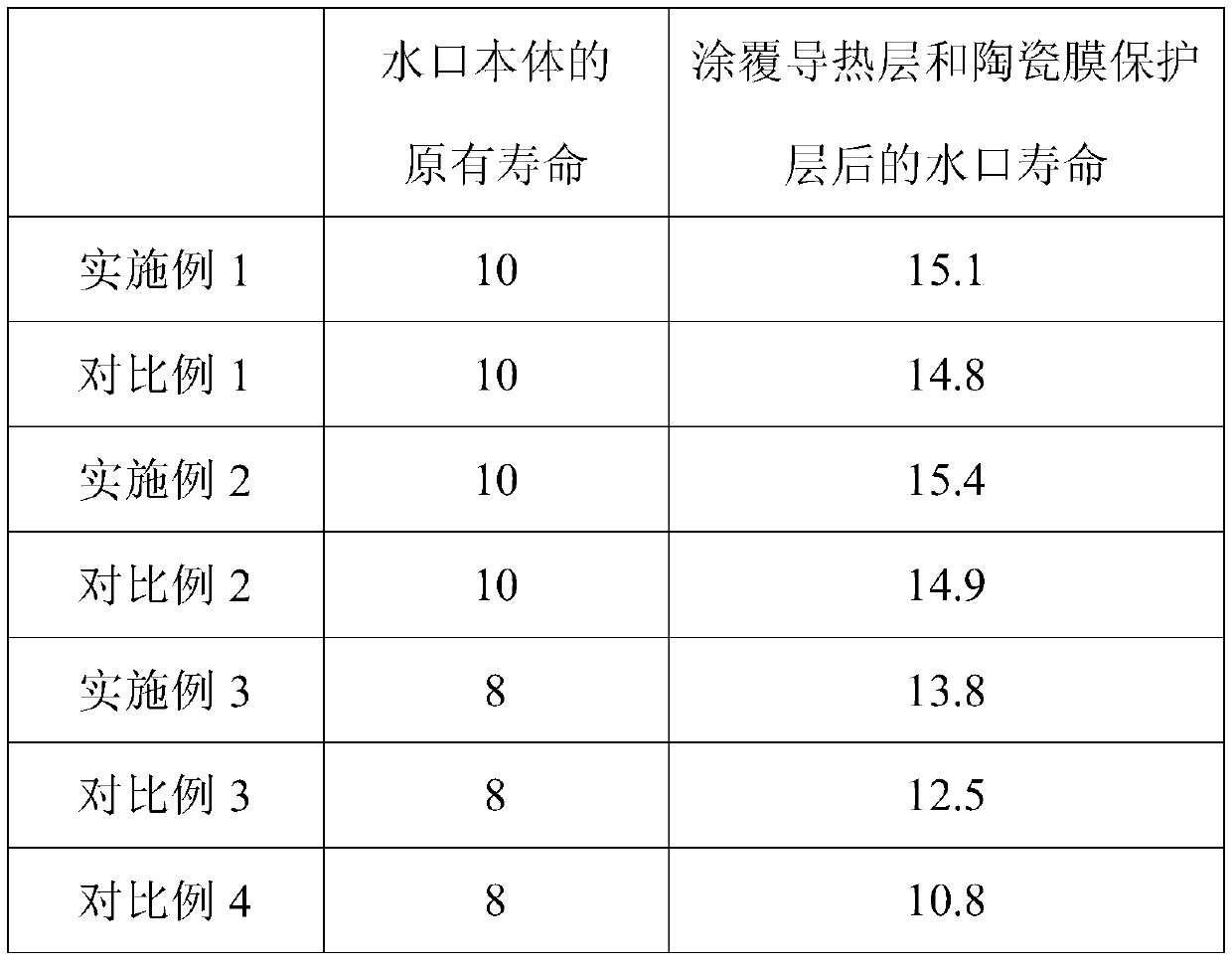

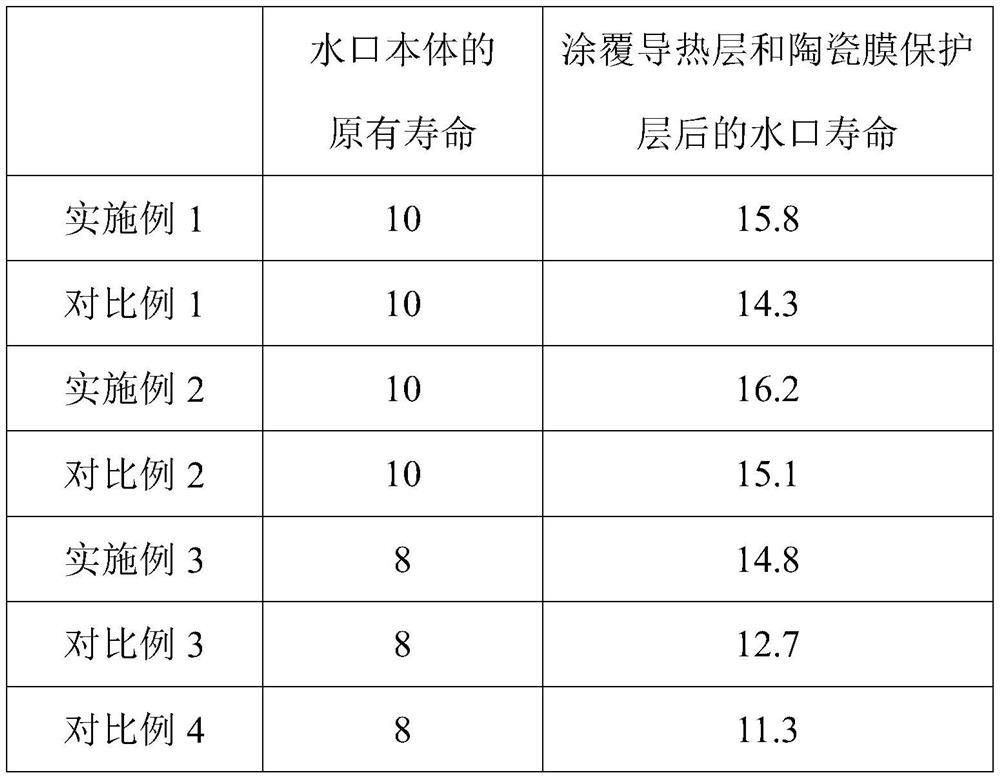

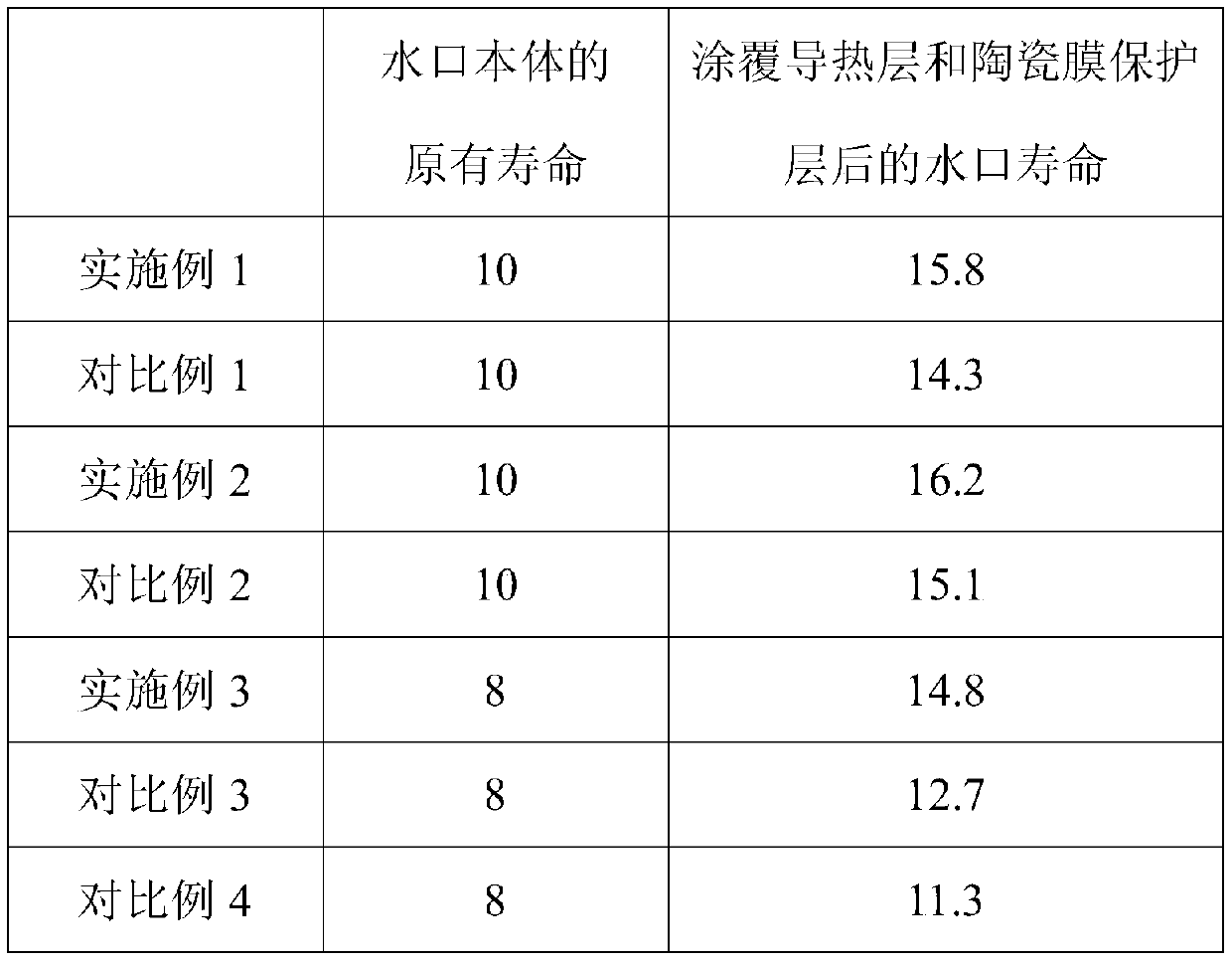

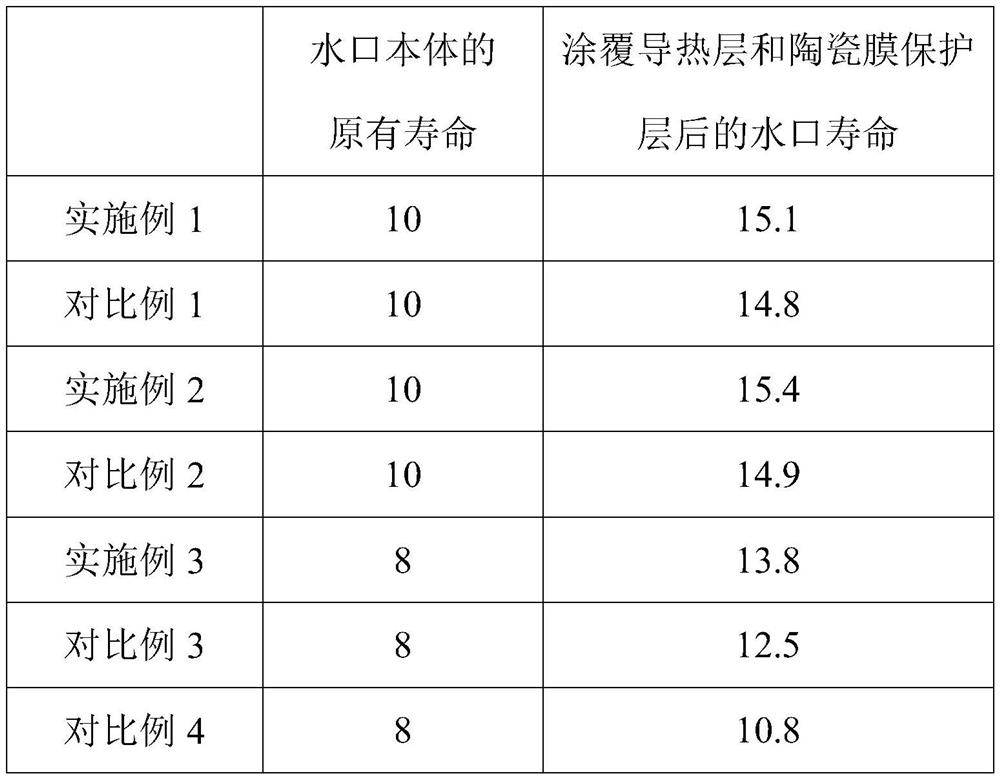

Preparation method of nozzle graphene refractory material

The invention provides a preparation method of a nozzle graphene refractory material, and the preparation method comprises the following steps: (1) firstly preparing a heat conducting layer, namely, mixing graphite powder, graphene powder, titanium carbide, tungsten carbide and a binder, and uniformly coating the working surface of a long nozzle or a submerged nozzle with the mixture, (2) preparing a ceramic membrane protective layer, namely, uniformly mixing Al2O3, SiN4, a binder, a lubricant, a dispersant and water, and then coating a heat conducting layer prepared in the step (1) with the mixture; (3) performing low-temperature calcination; (4) performing high temperature calcination. According to the invention, the high thermal conductivity of the graphite and the graphene is utilizedto rapidly disperse the thermal shock of molten steel to the whole long nozzle or submerged nozzle body, so that the heat accumulation in a local area of the nozzle is avoided, and each part of the nozzle can maintain the stability and firmness of the internal structure without the appearance of weak areas, and the working time of the nozzle as a whole is improved.

Owner:JIANGSU TAIRUI REFRACTORY

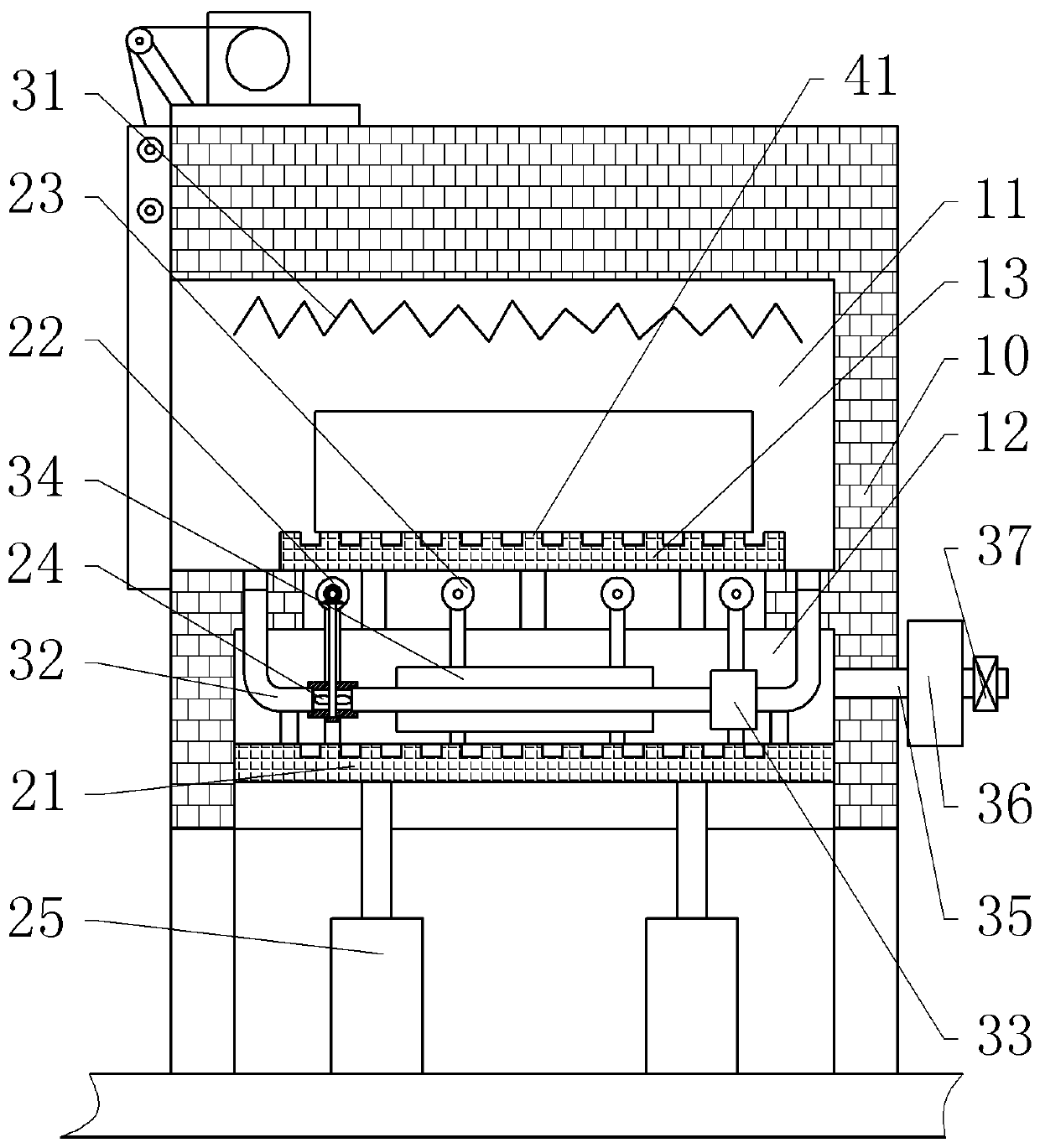

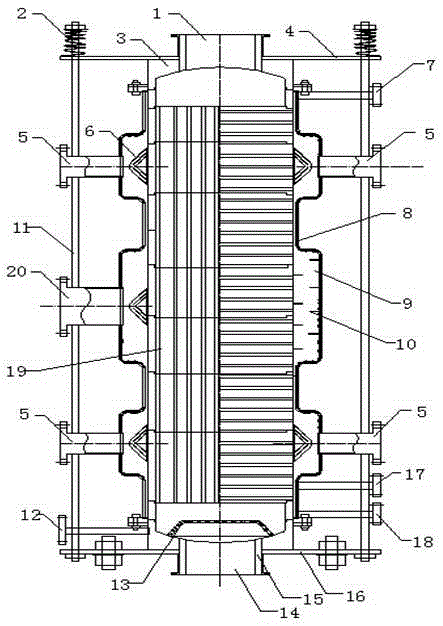

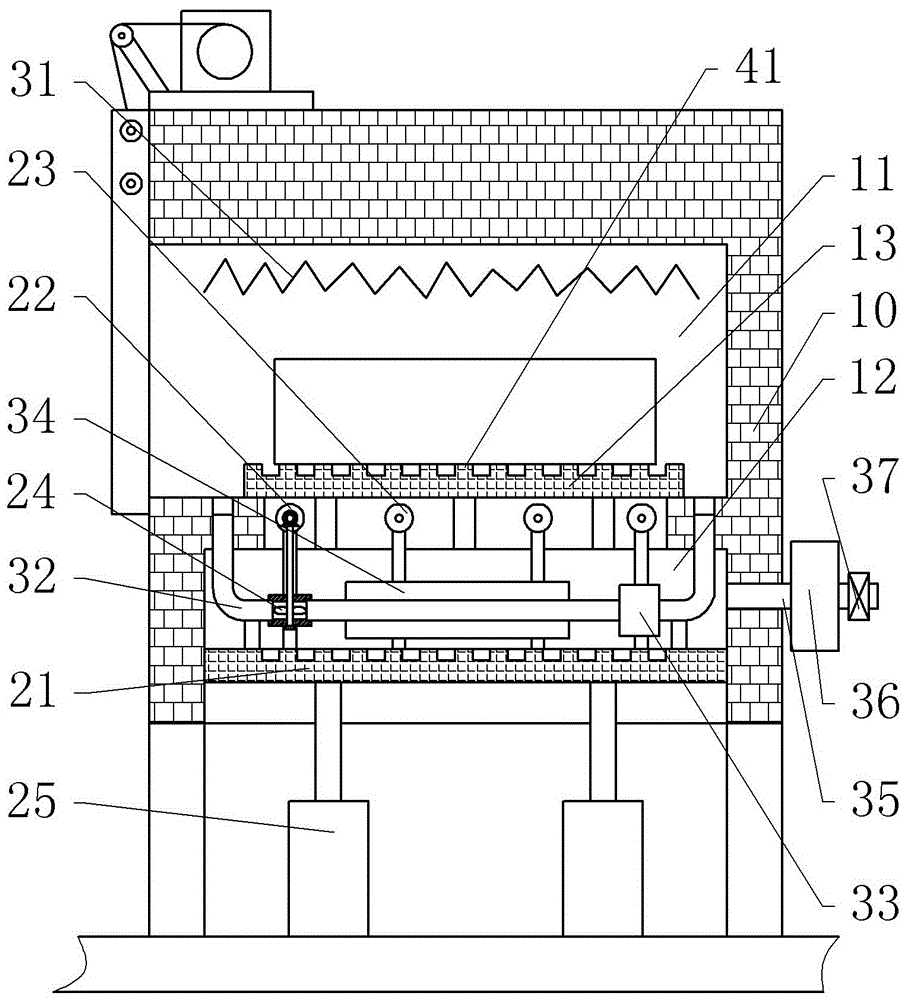

A heat treatment furnace

ActiveCN106755793BTake advantage ofImprove heat treatment efficiencyFurnace typesHeat treatment furnacesTemperature controlHeating furnace

The invention discloses a thermal treatment heating furnace, and relates to a heating device. The thermal treatment heating furnace comprises a furnace body, a feeding device and a temperature control device. A supporting pillar is fixed to the side wall of the inside of the furnace body, and a thermal baffle is placed on the supporting pillar. An annealing chamber is arranged above the thermal baffle, and a tempering chamber is arranged below the thermal baffle. The feeding device comprises a bearing plate which is arranged inside the tempering chamber and can be lifted up and down, and rollers which are arranged on the bearing plate. The temperature control device comprises a heater, an air hose, a circulating fan, a temperature sensor and a controller. The heater is installed inside the annealing chamber. The air hose is arranged inside the tempering chamber, and the two ends of the air hose are connected with the annealing chamber. The circulating fan is arranged on the air hose. Airflow in the air hose can further be used for driving the rollers to rotate. By means of the thermal treatment heating furnace, when workpieces are subjected to annealing treatment in the annealing chamber, other workpieces can be subjected to tempering treatment in the tempering chamber, tempering heat comes from the annealing chamber, and thus utilization efficiency of heat energy can be improved.

Owner:佛山市南海万格士机械设备有限公司

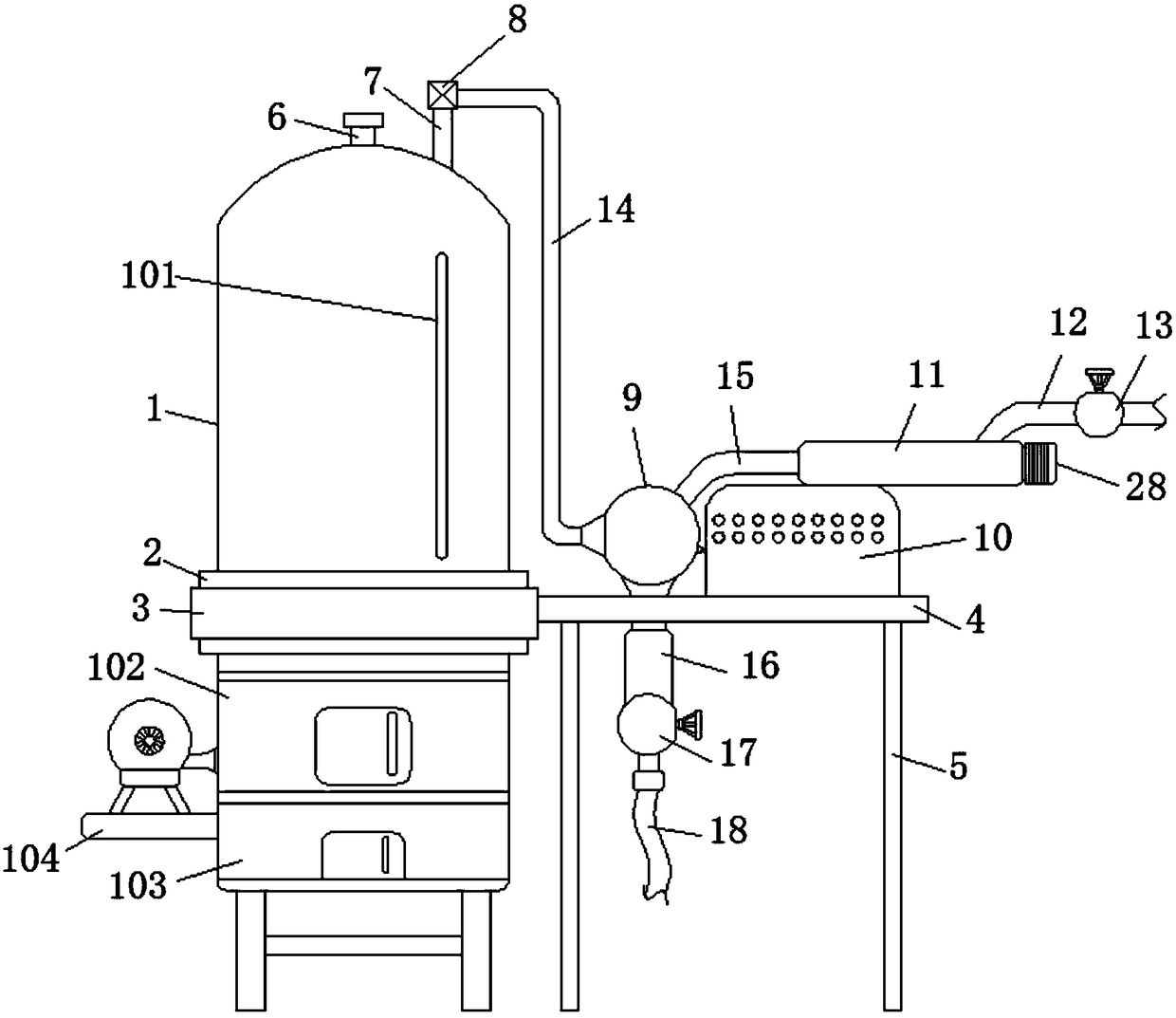

Steam generator with water filtering function

InactiveCN108730949AEvenly heatedAffect heatingTreatment involving filtrationBoiler cleaning apparatusWater filterSolenoid valve

The invention relates to the technical field of steam generator equipment, and discloses a steam generator with a water filtering function. The steam generator comprises a steam furnace. A heat insulating layer is arranged on the lower portion of the steam furnace. A fixing ring is arranged on the surface of the heat insulating layer. One side of the fixing ring is fixedly connected with a connecting seat. The bottom of the connecting seat is fixedly connected with connecting legs. A steam discharging pipe is arranged in the middle of the top of the steam furnace. One side of the top of the steam furnace is fixedly connected with a water adding pipe. A solenoid valve is arranged at the top of the water adding pipe. A secondary filtering mechanism is arranged on one side of the top of the connecting seat. Through arrangement of the secondary filtering mechanism and a primary filtering mechanism, tap water added into a boiler is subjected to double filtration, silt, small and shredded deadwood and dead leaves, rust and the like in the tap water are filtered, and the situations that a layer of dirt is formed on the inner wall of the boiler due to impurity accumulating after long-termuse, and consequently, heat transferring is affected, the usage amount of fuel coal is increased, the boiler is not evenly heated, and accordingly, heating of water is affected are avoided.

Owner:安徽亿达新能源科技有限公司

Graphite evaporator for concentration by evaporation and automatic control system thereof

ActiveCN105396303AIncrease profitImprove heat transfer efficiencyEvaporationSimultaneous control of multiple variablesAutomatic controlEvaporation

The invention provides a graphite evaporator for concentration by evaporation. The graphite evaporator comprises a housing, a waveform heat insulating layer is spread on an inner wall of the housing, a corrosion preventing composite layer is spread on an outer wall of the housing, and the housing is made from stainless steel; the upper part, the middle part and the lower part of the housing are separately provided with a loop of steam distributor, sides of each of the steam distributors at the upper part and the lower part of the housing are provided with steam inlets, a steam inlet passage is arranged at one side of the steam distributor in the middle part of the housing, automatic control systems are connected to the steam inlets, and a steam outlet is arranged above one side of the steam inlet at the upper part of the housing; several U-shaped grooves and lateral through holes are arranged at the outside of graphite heat exchange blocks, and places between every two layers of the graphite heat exchange blocks are sealed with fluororubber. The graphite evaporator has the advantages of improved steam utilization rate, enhanced corrosion resistance, high temperature resistance and high pressure resistance, prolonged service life, and excellent performance; and automatic control is realized at the same time. The invention also comprises an automatic control system for controlling the graphite heat exchanger for concentration by evaporation.

Owner:PINGDINGSHAN XINRUIDA NEW MATERIAL TECH CO LTD

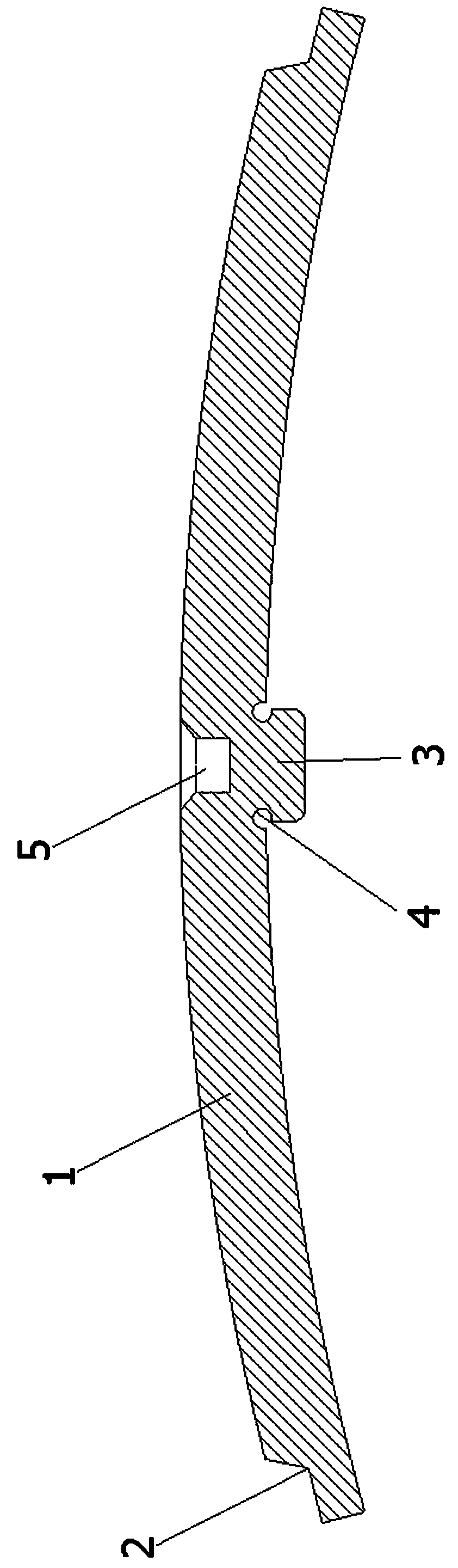

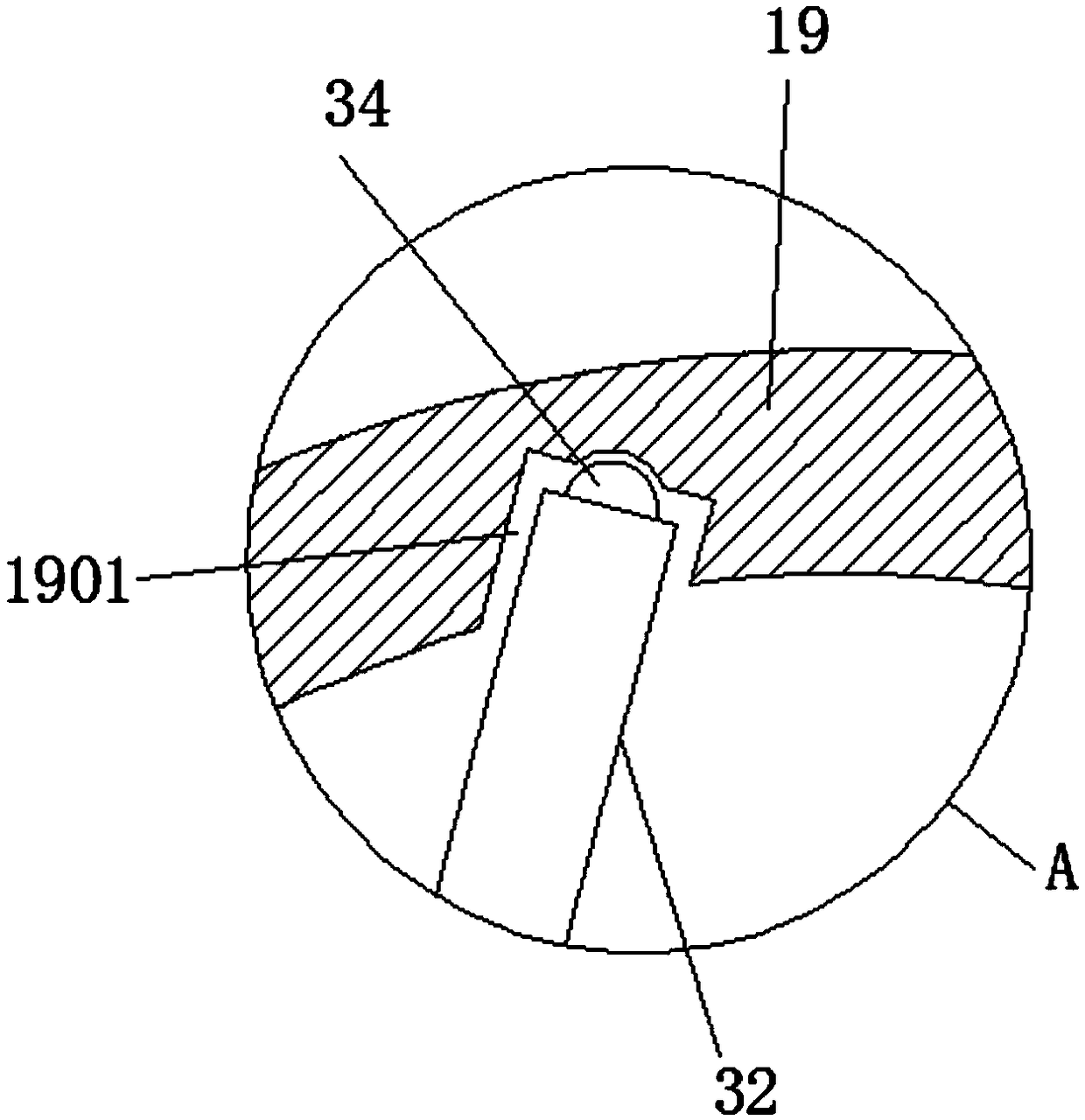

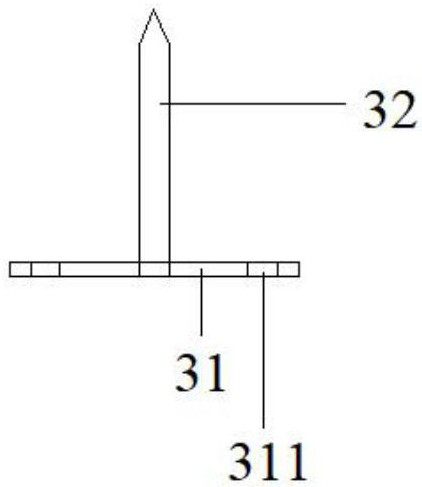

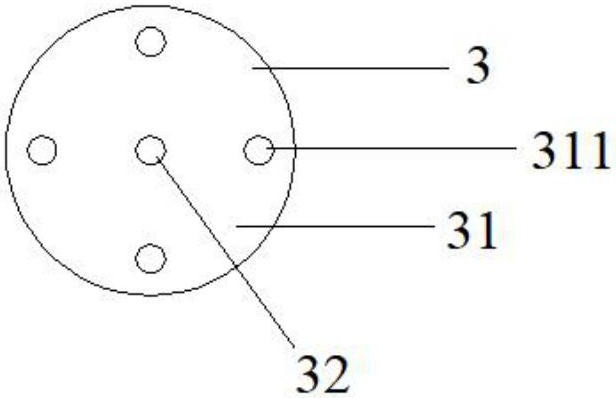

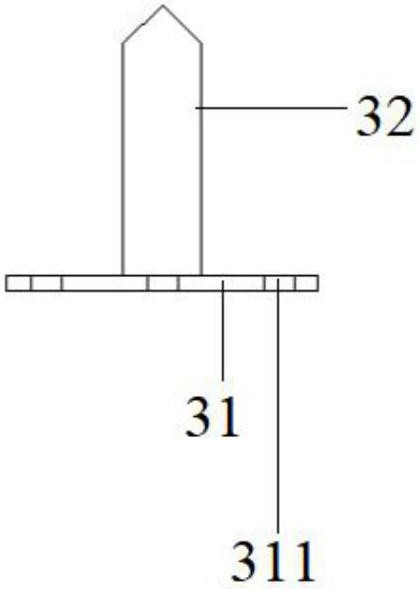

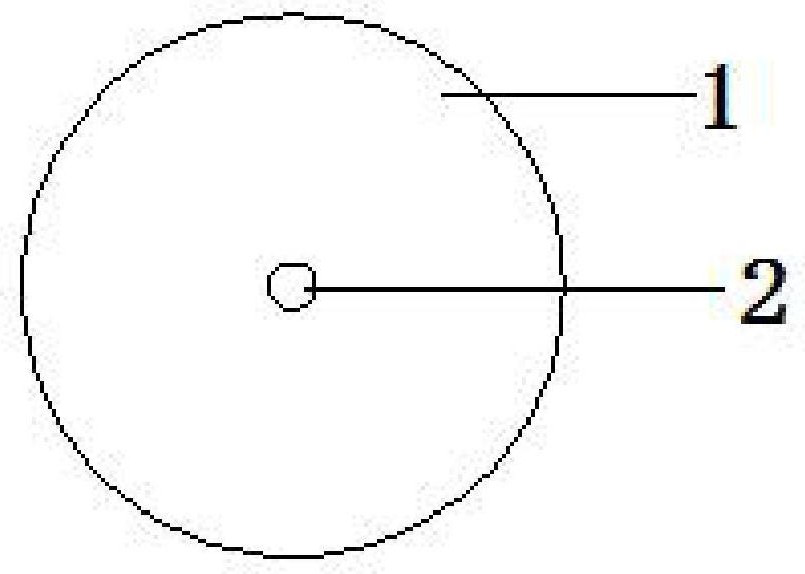

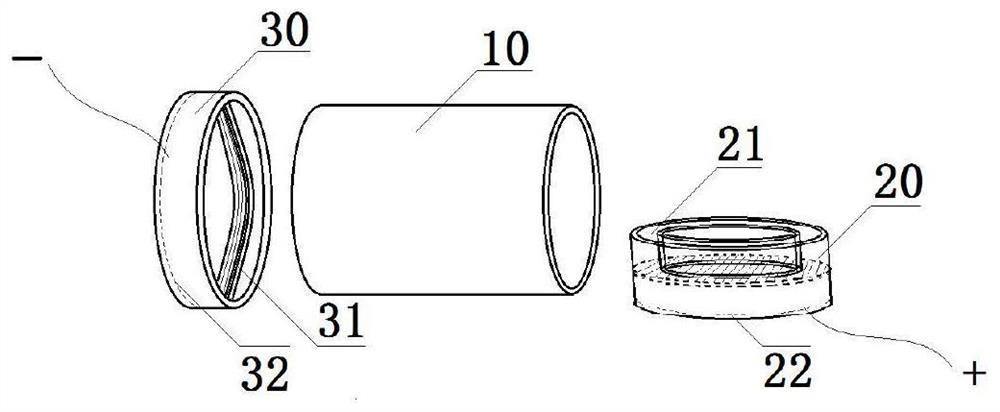

Aerosol generating product sealing assembly and electromagnetic aerosol generating product comprising same

PendingCN113439871AImprove the heating effectShorten warm-up timeCigar manufactureThermodynamicsEngineering

The invention discloses an aerosol generating product sealing assembly and an electromagnetic aerosol generating product comprising the same, the aerosol generating product comprises an upstream aerosol generating base material (1) and a downstream filtering part (2), and the sealing assembly is located at the upstream end of the aerosol generating base material (1); the sealing assembly comprises a sealing cap (31) and a heat conduction part (32); the sealing cap (31) is positioned at the end part of the upstream end of the aerosol generating base material (1) and is made of a magnetic conductive material; the upstream end of the heat conduction component (32) is connected with the sealing cap (31), the downstream end of the heat conduction component (32) extends towards the interior of the aerosol generating base material (1), and the heat conduction component (32) is made of heat conduction materials. The sealing assembly can play a role in blocking the granular aerosol generating material, on the other hand, the sealing cap (31) is matched with an electromagnetic heating appliance and emits heat under the action of electromagnetic induction, and meanwhile, the heat conduction component (32) transmits heat to the aerosol generating base material. The magnetoelectric aerosol generating product is suitable for an appliance adopting an electromagnetic heating principle, the heating effect is greatly improved, and the preheating time is greatly shortened.

Owner:YUNNAN XIKE TECH CO LTD

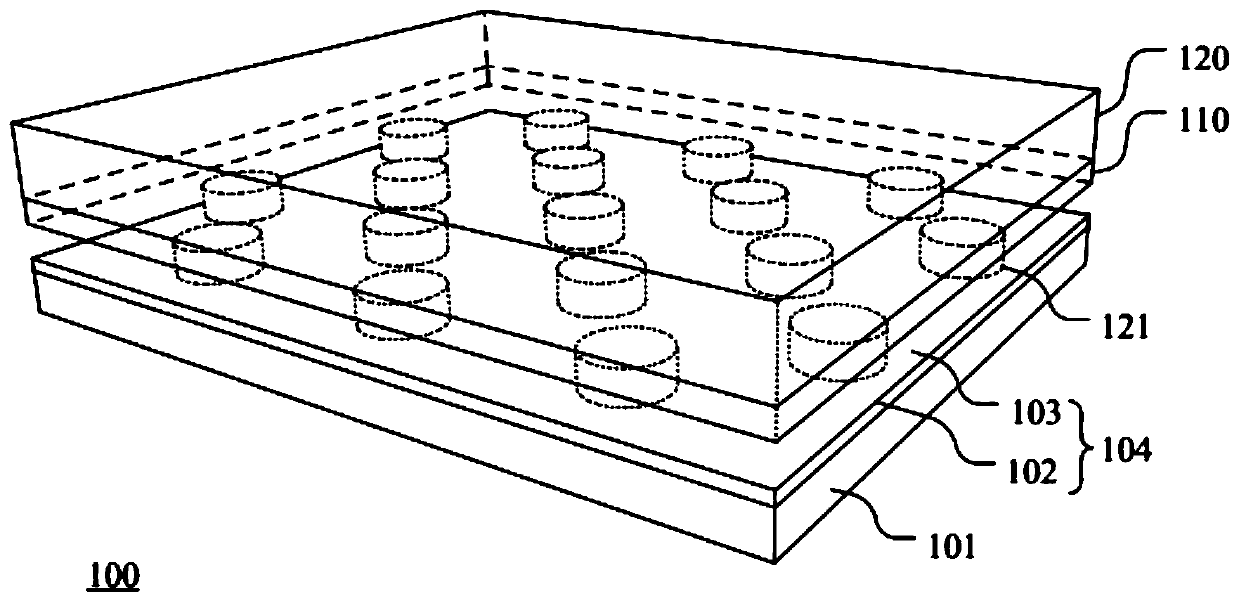

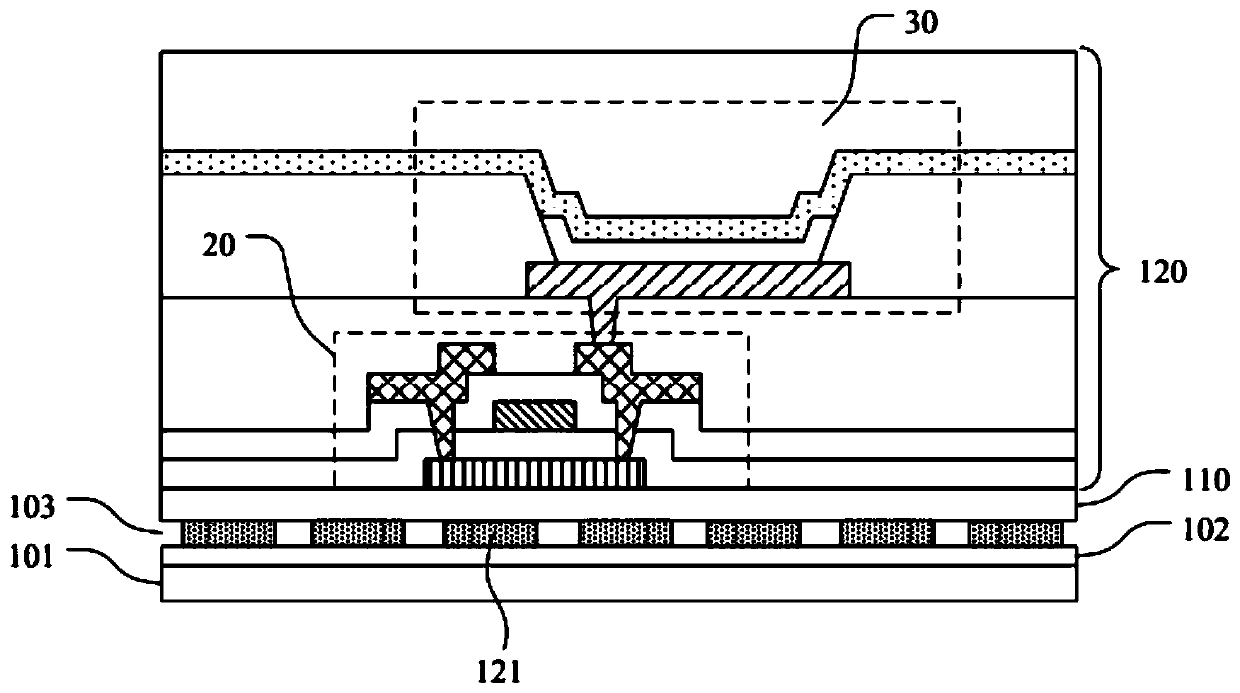

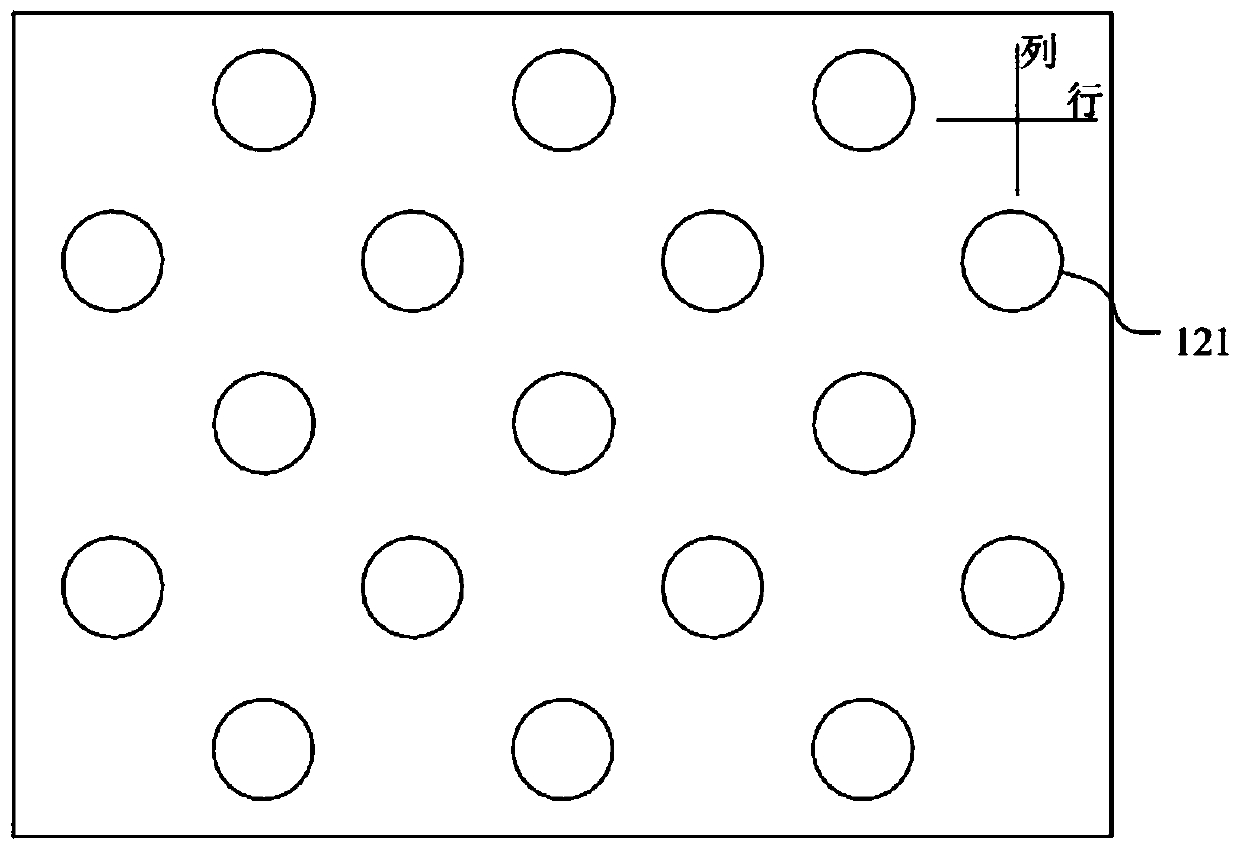

Release layer structure and preparation method of display panel

ActiveCN111554186AUneven heatingAvoid Adhesive DamageFinal product manufacturePhotovoltaic energy generationMechanical engineeringHeat energy

The invention discloses a release layer structure, a substrate structure and a preparation method of a display panel, and the release layer structure comprises: a thermal induction layer which is in contact with a local surface of a display substrate in a strippable manner; and a heat conduction layer which is arranged between the thermal induction layer and the substrate base plate so as to provide heat energy for a local surface of the display base plate through the thermal induction layer. According to the release layer structure, the substrate structure and the preparation method of the display panel provided by the invention, the heat conduction layer and the thermal induction layer are arranged between the display substrate and the substrate, different positions of the display substrate are heated unevenly in the stripping process, the stripping force between the display substrate and the thermal induction layer is reduced, and therefore the display substrate and the underlayer substrate can be separated rapidly without damage, and the stripping cost is low.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Thermal treatment heating furnace

ActiveCN106755793ATake advantage ofImprove heat treatment efficiencyFurnace typesHeat treatment furnacesTemperature controlHeating furnace

The invention discloses a thermal treatment heating furnace, and relates to a heating device. The thermal treatment heating furnace comprises a furnace body, a feeding device and a temperature control device. A supporting pillar is fixed to the side wall of the inside of the furnace body, and a thermal baffle is placed on the supporting pillar. An annealing chamber is arranged above the thermal baffle, and a tempering chamber is arranged below the thermal baffle. The feeding device comprises a bearing plate which is arranged inside the tempering chamber and can be lifted up and down, and rollers which are arranged on the bearing plate. The temperature control device comprises a heater, an air hose, a circulating fan, a temperature sensor and a controller. The heater is installed inside the annealing chamber. The air hose is arranged inside the tempering chamber, and the two ends of the air hose are connected with the annealing chamber. The circulating fan is arranged on the air hose. Airflow in the air hose can further be used for driving the rollers to rotate. By means of the thermal treatment heating furnace, when workpieces are subjected to annealing treatment in the annealing chamber, other workpieces can be subjected to tempering treatment in the tempering chamber, tempering heat comes from the annealing chamber, and thus utilization efficiency of heat energy can be improved.

Owner:佛山市南海万格士机械设备有限公司

Electric heating air blow constant-temperature drying box

InactiveCN107763994APrevent proliferationUneven heatingDrying gas arrangementsDrying solid materialsDrive wheelEngineering

The invention relates to the technical field of constant temperature drying boxes, and discloses an electric blast constant temperature drying box, comprising a drying box, a chassis is fixedly installed at the bottom of the drying box, a motor is fixedly installed at the bottom of the inner cavity of the box, and the motor A driving wheel is fixedly fitted on the output shaft of the driving wheel, the outer teeth of the driving wheel mesh with the driven wheel, the middle part of the driven wheel is fixedly fitted with a rotating rod, and one end of the rotating rod is fixedly fitted with a The rotating bearing, one end of the rotating rod passes through the outside of the cabinet and extends to the inside of the drying box. The electric blast constant temperature drying oven, through the cooperation of the driving wheel and the passive theory, makes the rotating rod drive the tray to rotate, and uses the cooperation of the sliding block and the guide rail to make the driving plate drive the baffle Ⅰ to rotate, preventing the temperature of the drying box from spreading evenly. Avoid some places where the temperature is high and some places where the temperature is low, which will affect the uneven heating of objects.

Owner:李笑美

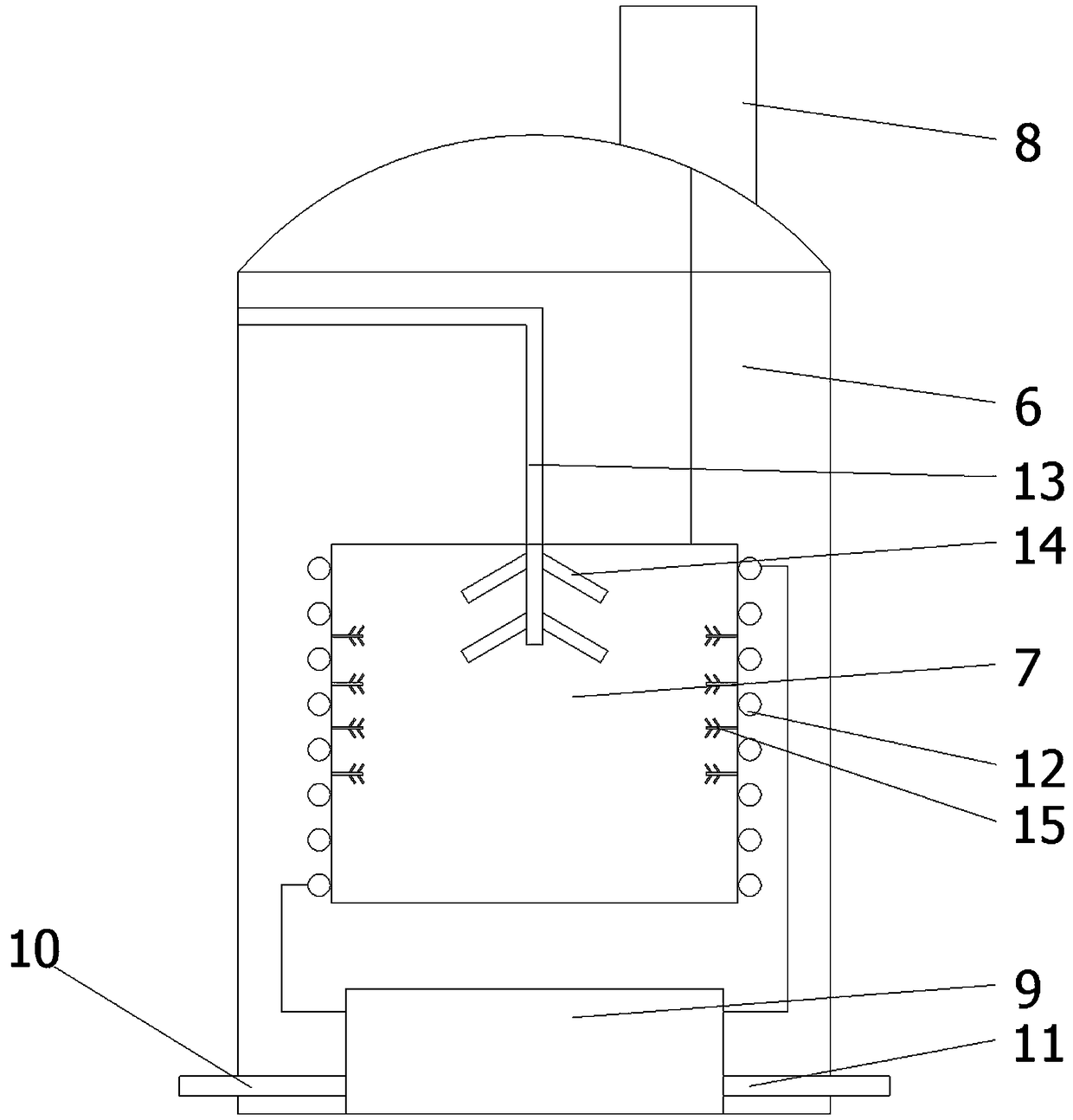

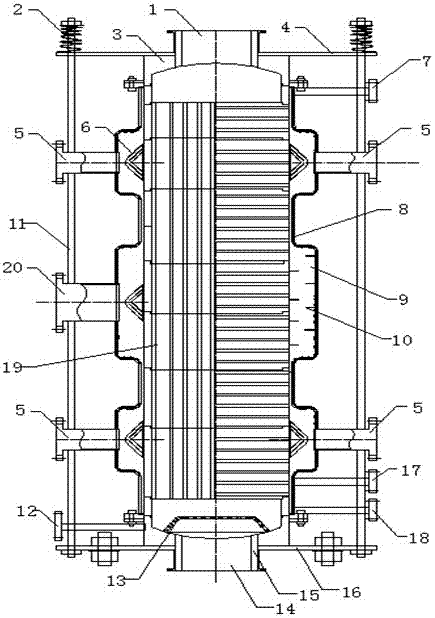

Boiler overheater

The invention discloses a boiler overheater. The boiler overheater structurally comprises an inner heating plate, an upper cover, vertical heat conduction fins, connecting detachment joints, overheater pipes, a shell, side face heat conduction fins, a saturated steam input pipeline and an overheated steam output pipeline. An oil bath groove is additionally formed in the boiler overheater, steam heating is uniform, and the situation that overheater heating is uneven, and consequently complete water removal of saturated steam happens is avoided. Meanwhile, single-joint pipeline detaching and connecting type connection is adopted, the length of the overheater can be freely combined according to the situation, the resource is effectively utilized, resource allocation is maximal, and waste is avoided. Meanwhile, single-joint pipeline detaching and connecting type connection is adopted, overheater dismounting, mounting and overhauling are convenient, and the work efficiency is greatly improved; and meanwhile multi-direction fins are adopted on the outer side of the shell, shell heat absorbing is accelerated, the temperature utilization rate is increased, the contact area between the shell and oil in the shell is increased through the inner heating plate in the shell, and the heating efficiency is improved.

Owner:JIANGSU ZHONGKE HEAVY IND CO LTD

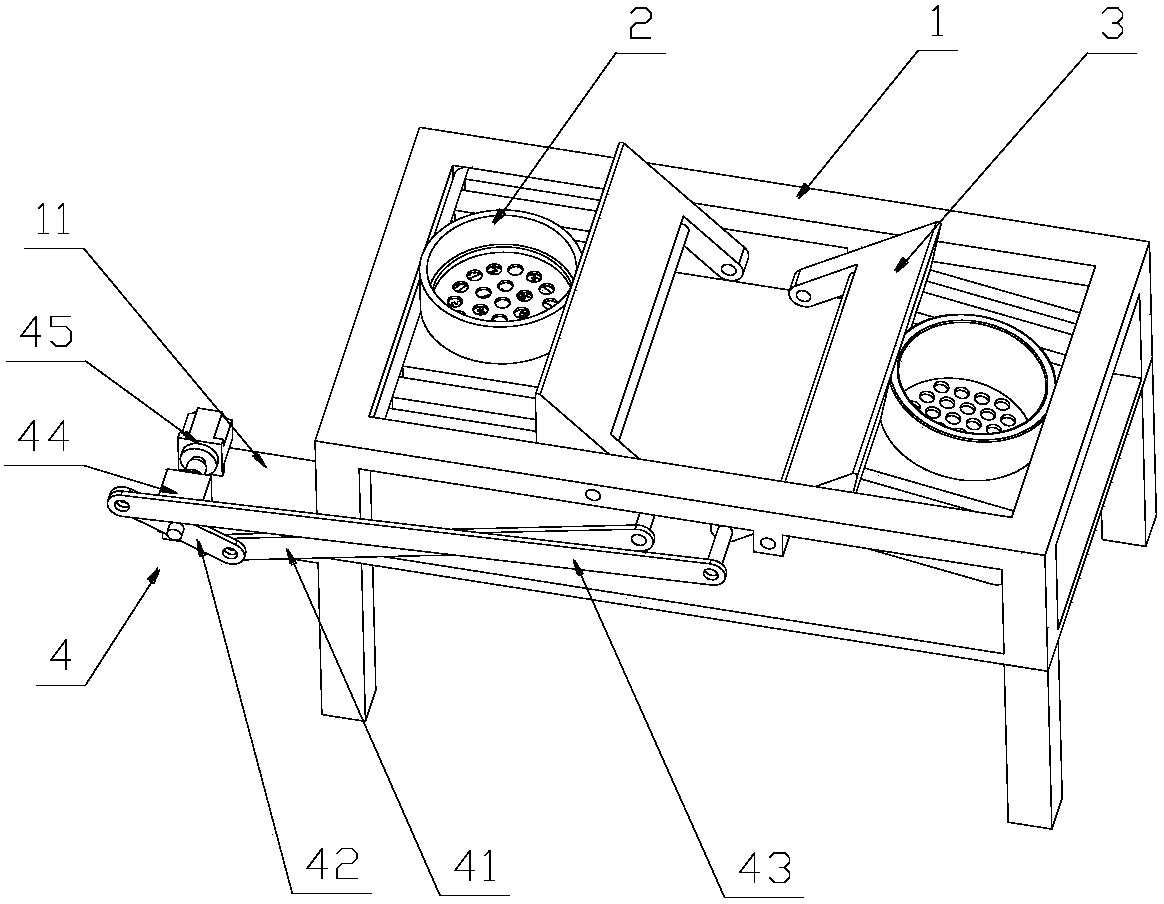

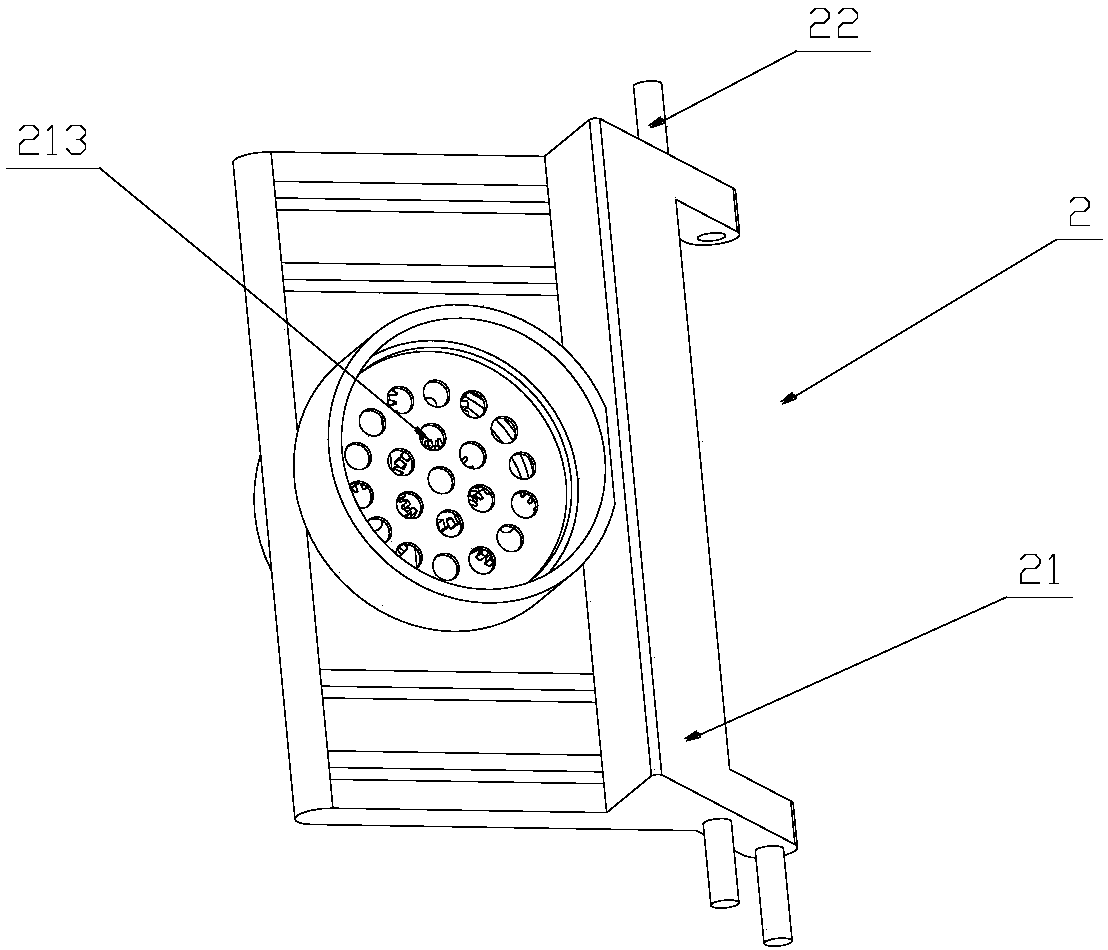

Cooking device for pet food

The present invention provides a cooking device for pet food and belongs to the technical field of production devices for the pet feed. A technical scheme is as follows: the cooking device for the petfood comprises an operation table; one side of the operation table is provided with a cooking mechanism; the other side of the operation table is provided with a fishing mechanism; and a connecting rod transmission mechanism is arranged between the cooking mechanism and the fishing mechanism. Beneficial effects are as follows: vegetables can be uniformly heated; natural gas and electric resourcesare saved; the cooking device can quickly fish out the completely cooked vegetables and air-dry the vegetables; and the vegetables do not need to be placed in cold water for cooling, thereby saving water resources.

Owner:QINGDAO AGRI UNIV

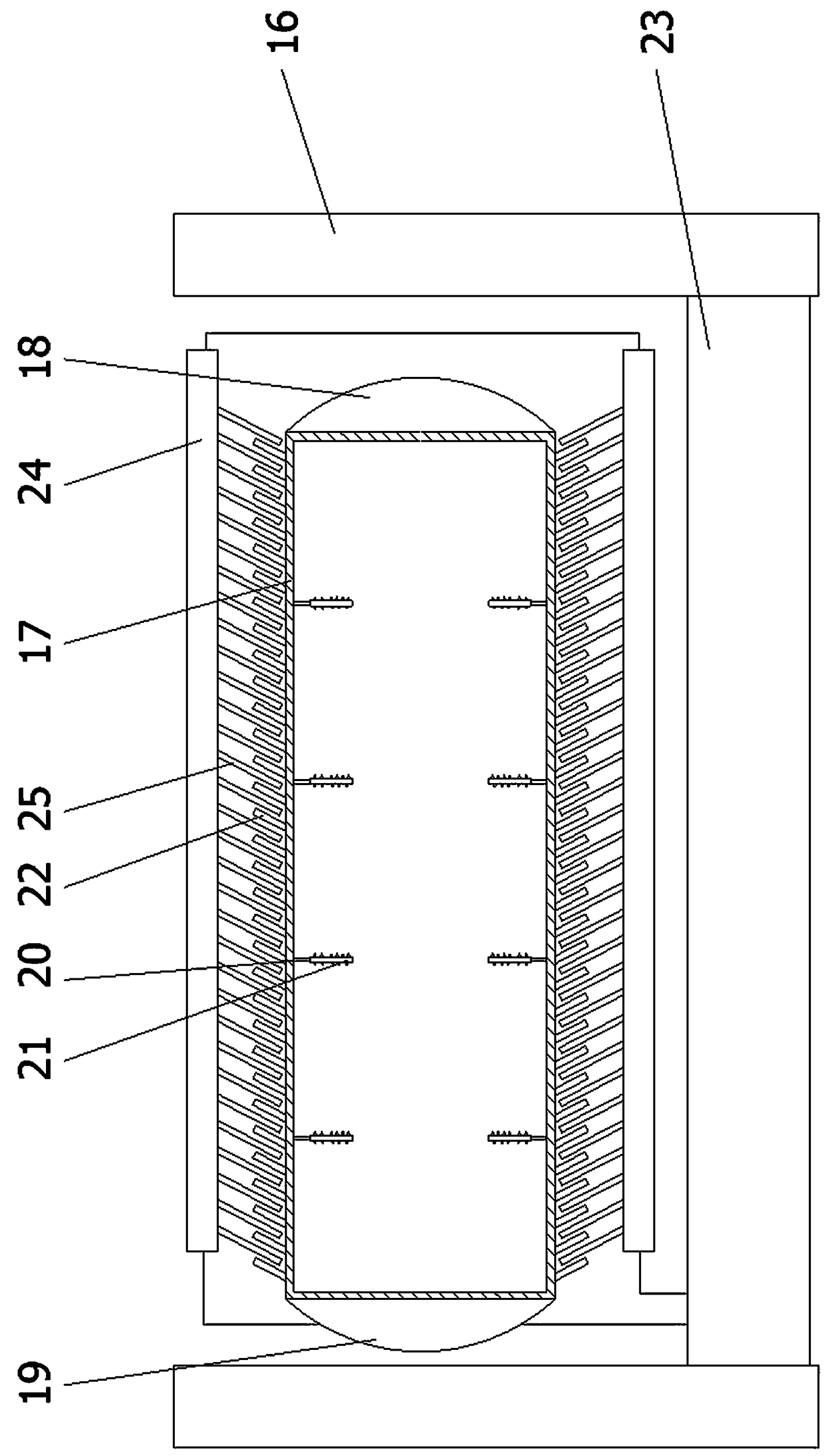

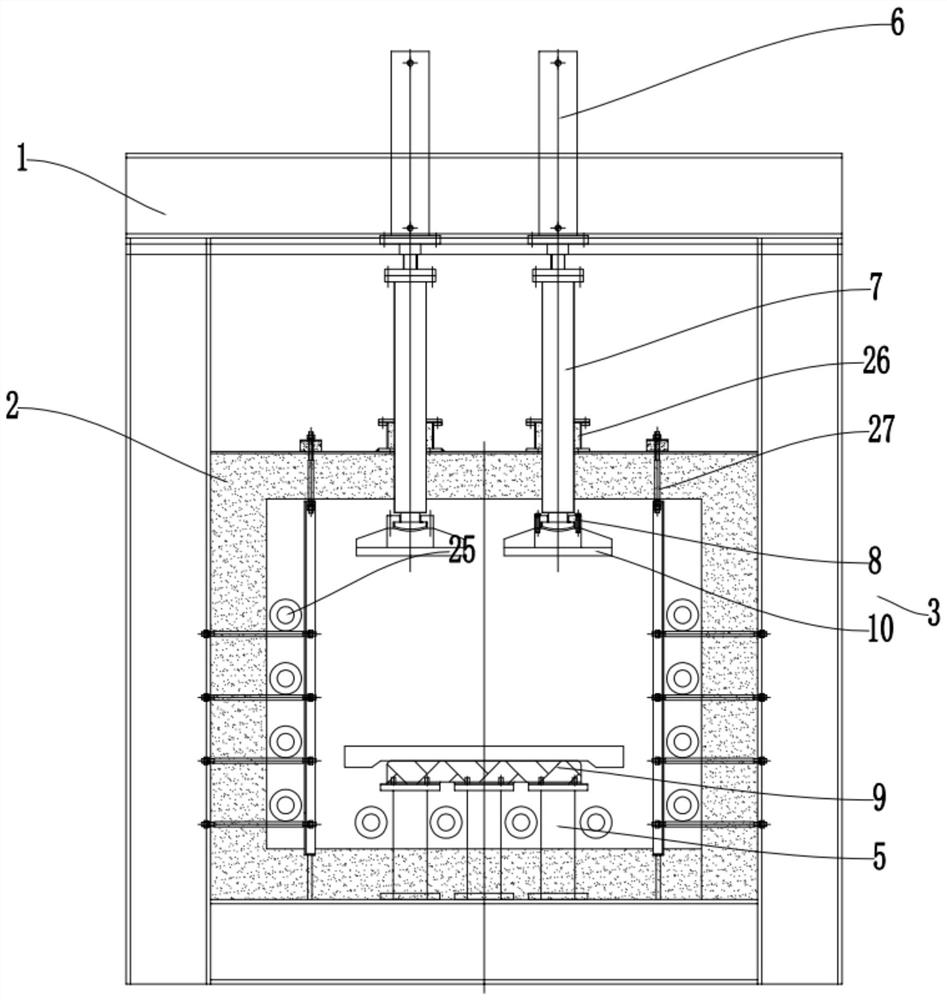

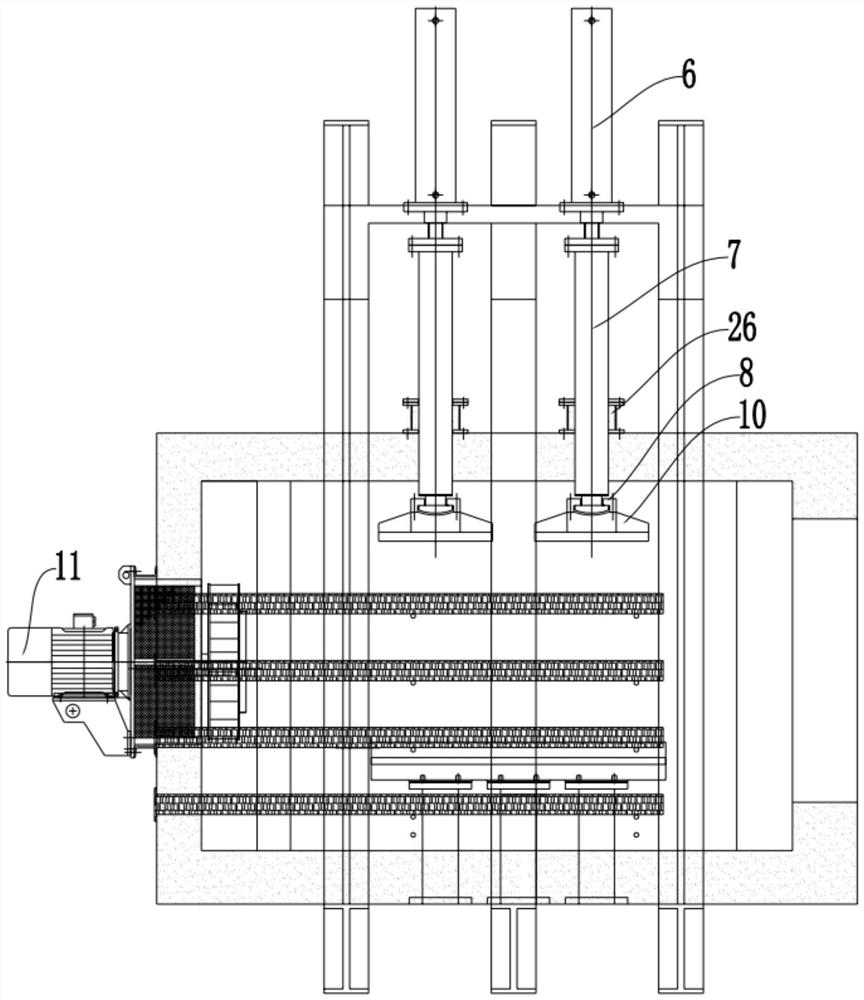

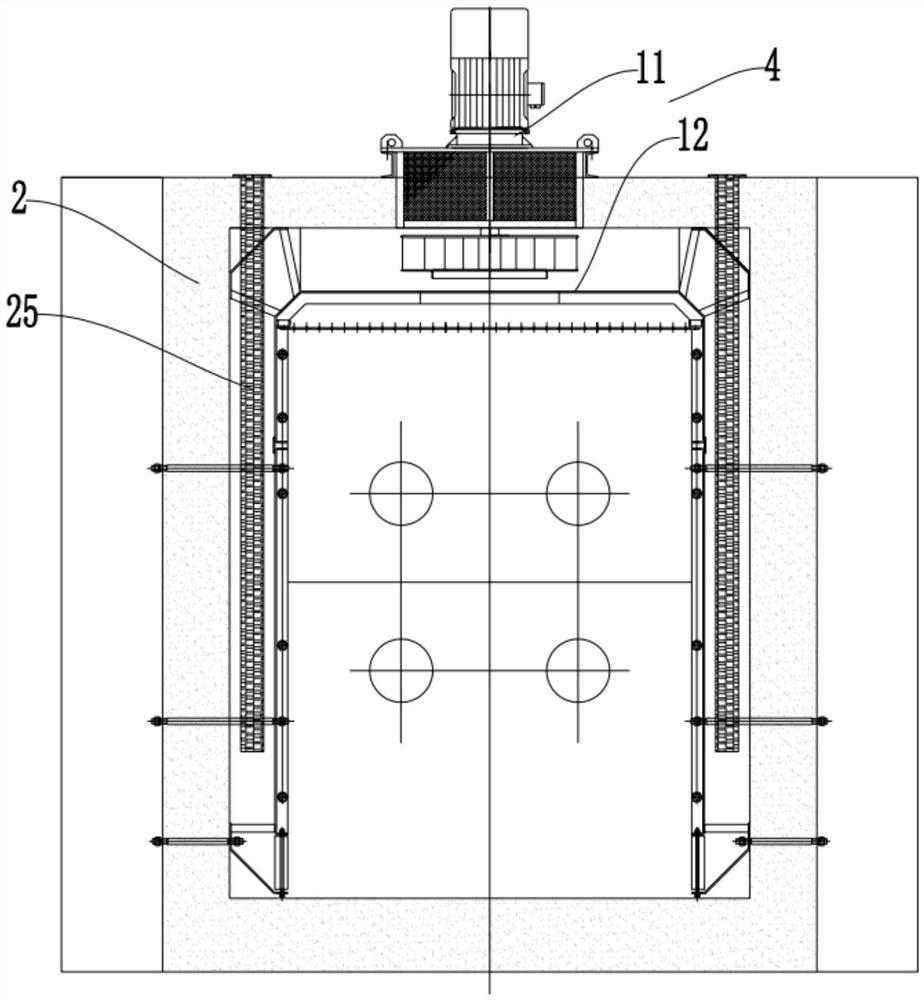

Tempering furnace air duct convenient to maintain and repair

PendingCN114293000ASmall footprintUniform temperatureFurnace typesHeat treatment furnacesTemperingEngineering

The tempering furnace air duct convenient to maintain and repair comprises an outer supporting frame, an inner cover, a pressurizing assembly and a heating circulation assembly, the inner cover is arranged in the outer supporting frame, the lower end of the pressurizing assembly and the heating circulation assembly are both arranged in the inner cover, and the heating circulation assembly is arranged on the outer side of the pressurizing assembly in a sleeving mode; the pressurizing assembly comprises a lower pressing rod, an oil cylinder, an upper pressing rod and a bearing bush, the lower pressing rod is arranged at the inner bottom of the inner cover, a lower pressing disc is arranged at the upper end of the lower pressing rod, the oil cylinder is arranged at the upper end of the outer supporting frame, the lower pressing rod is arranged at the telescopic end of the oil cylinder, and the lower end of the lower pressing rod penetrates through the upper end of the inner cover and is arranged in the inner cover; the lower end of the lower pressing rod is connected with an upper pressing disc. The invention belongs to the technical field of tempering furnace air ducts, and particularly provides a tempering furnace air duct convenient to maintain and repair. The tempering furnace air duct convenient to maintain and repair is simple in structure, high in workpiece tempering stability, high in tempering efficiency, convenient to maintain and low in maintenance difficulty.

Owner:SHANDONG HEIXUANFENG SAW IND

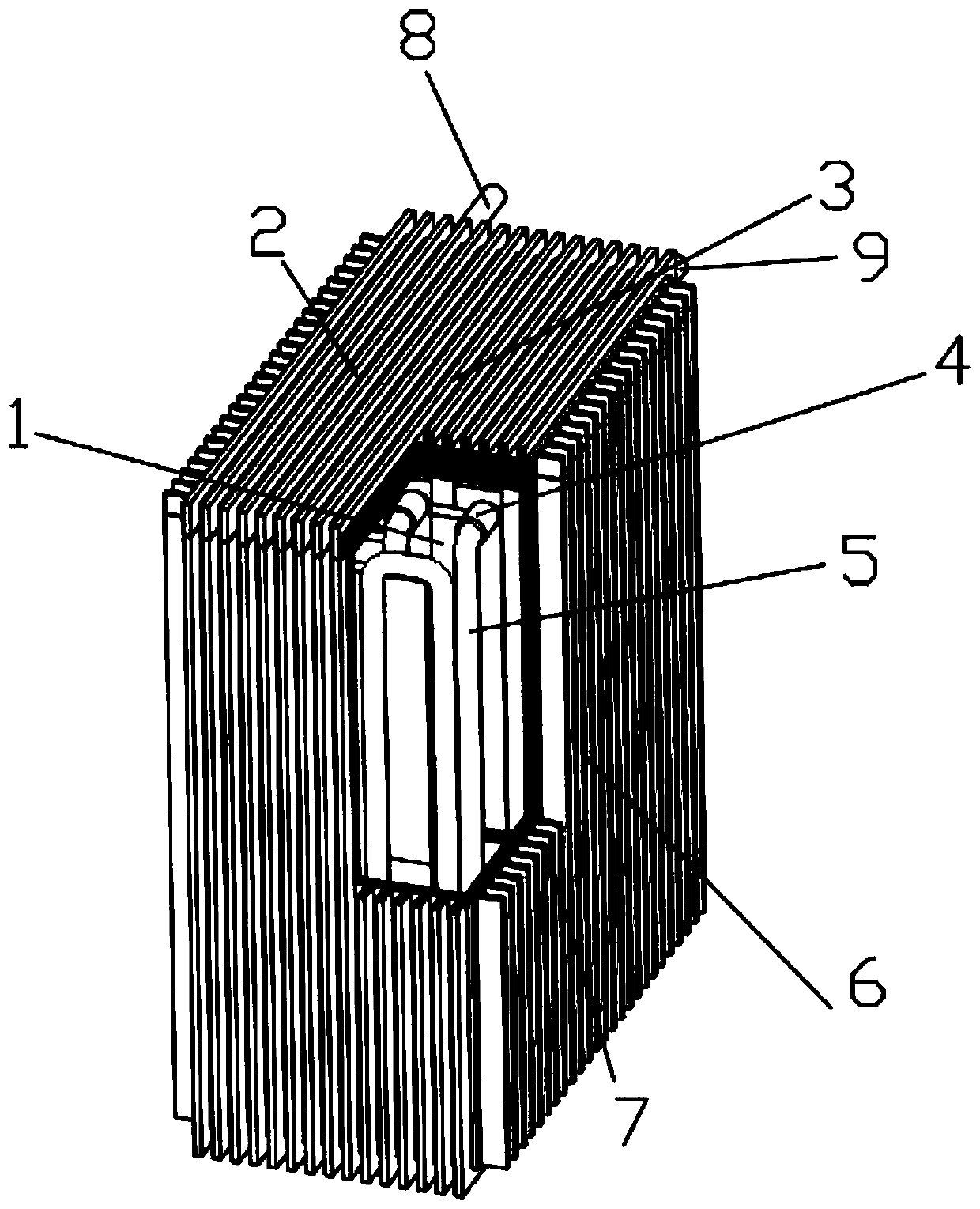

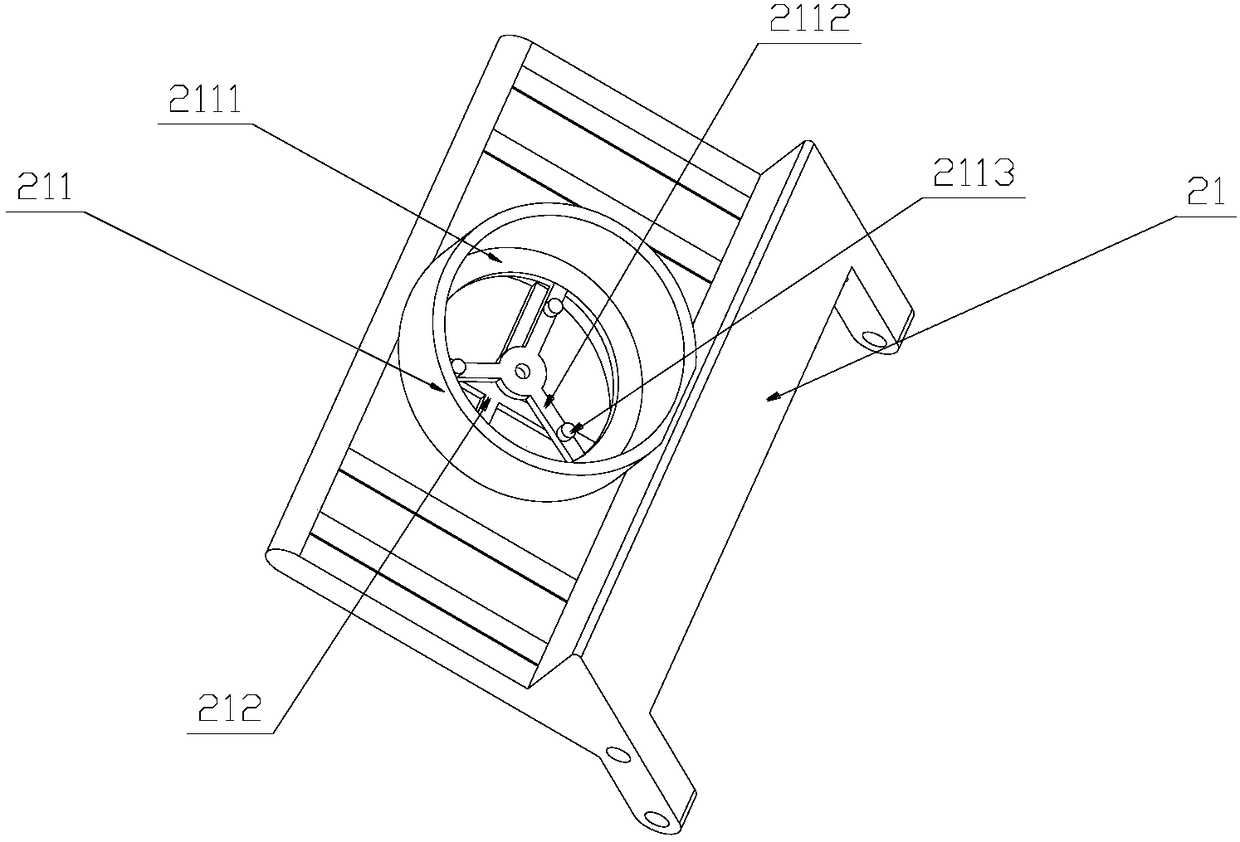

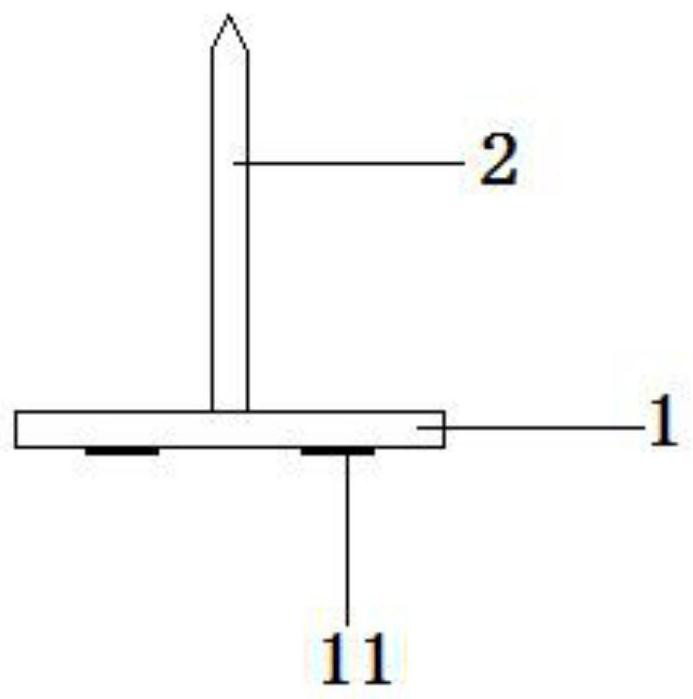

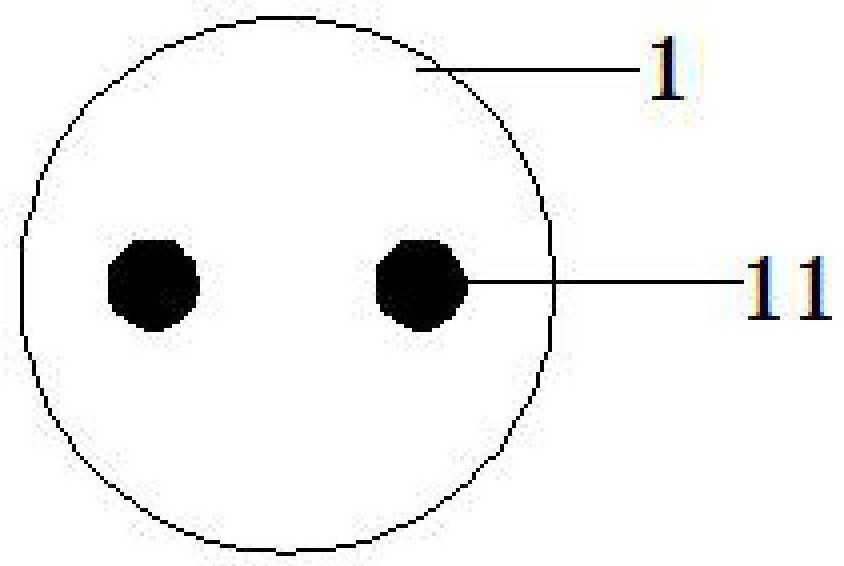

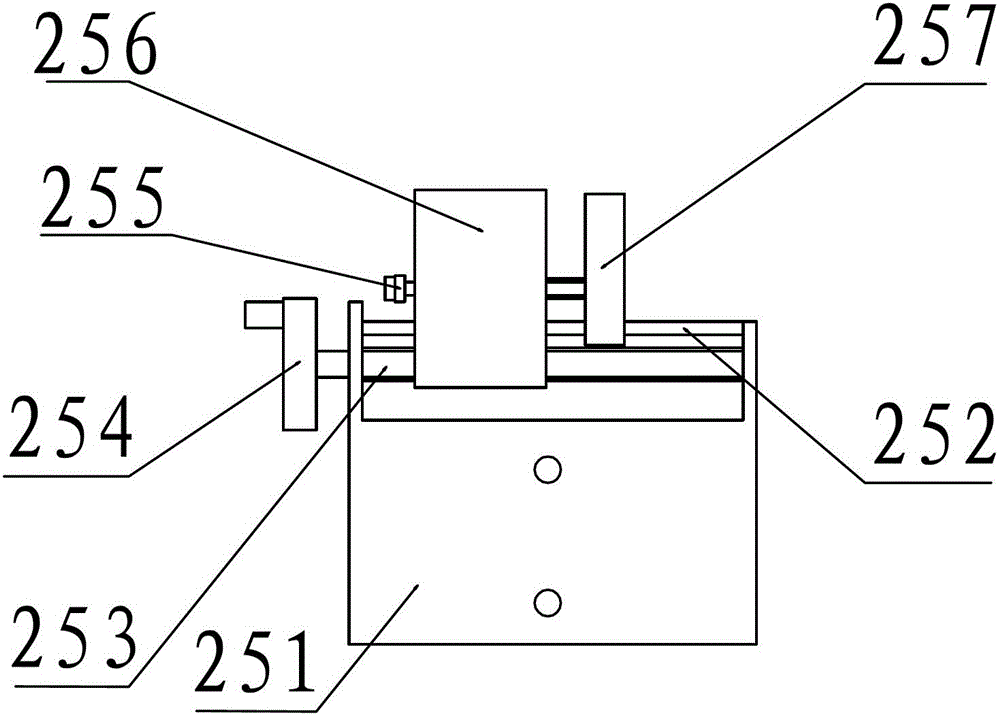

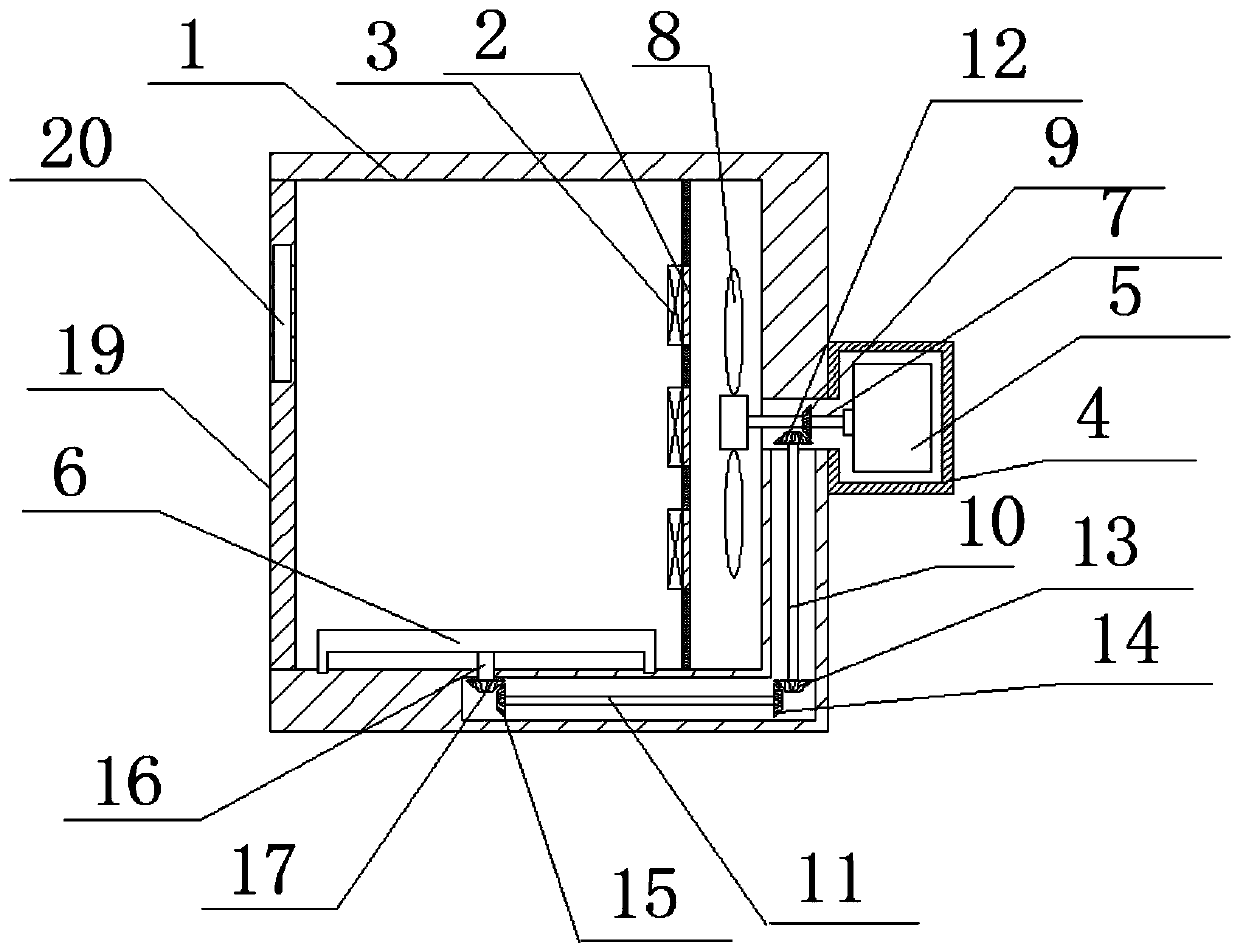

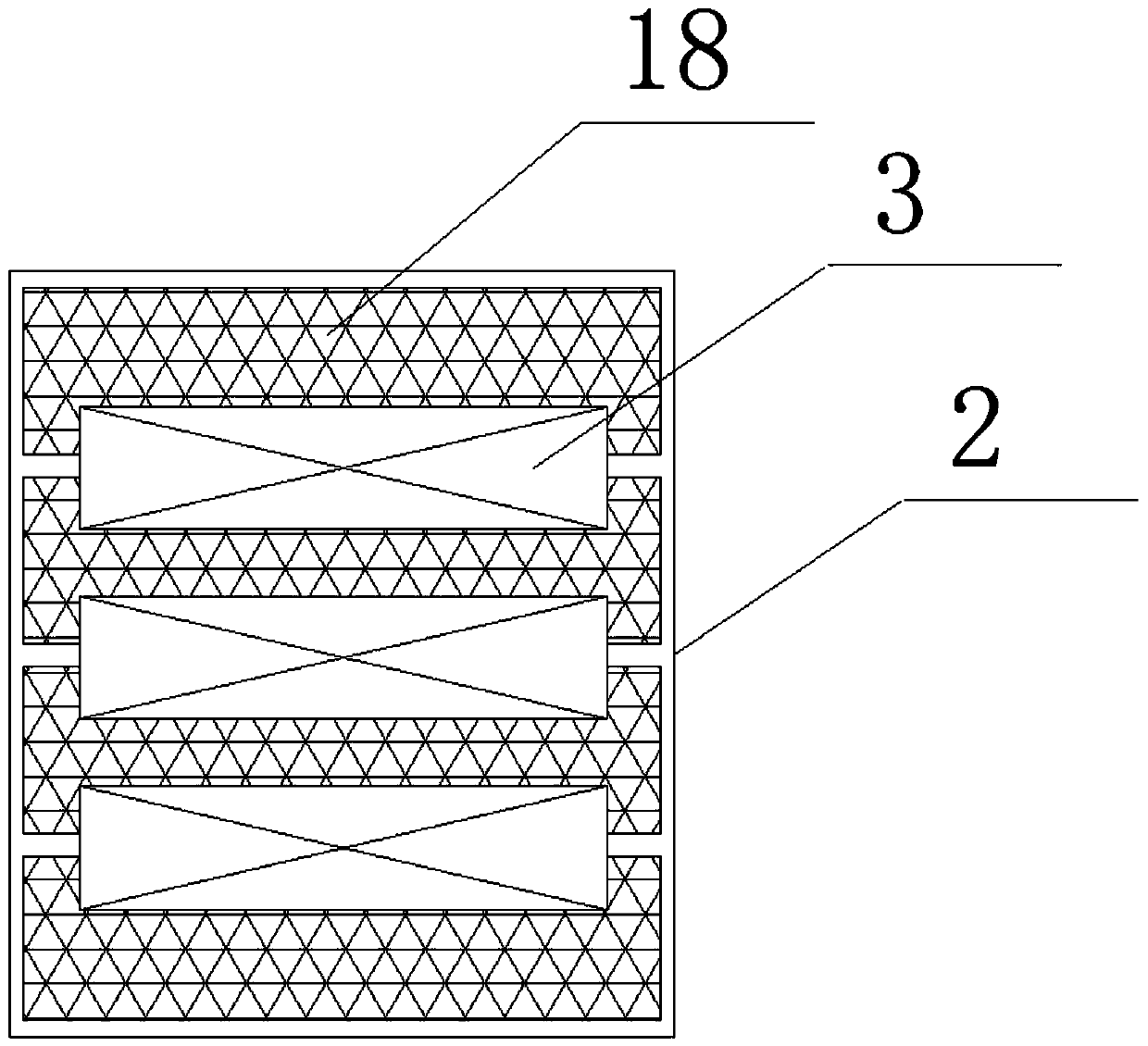

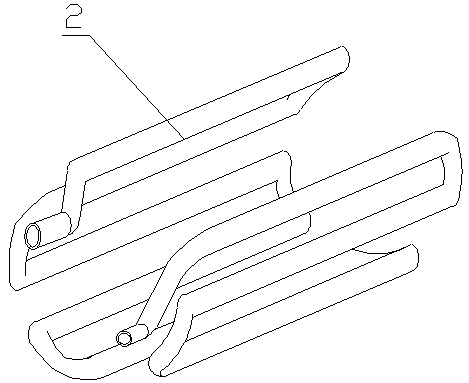

Detachable and reusable electromagnetic heating component and electromagnetic heating smoking set comprising same

PendingCN113412970AImprove the heating effectShorten warm-up timeTobaccoInduction heating apparatusElectromagnetic generatorEngineering

The invention discloses a detachable and reusable electromagnetic heating component and an electromagnetic heating smoking set comprising the same, the electromagnetic heating component is matched with the electromagnetic heating smoking set for use, and the electromagnetic heating component comprises an electromagnetic base (1) and a heat conduction extending part (2); the electromagnetic base (1) can be magnetically attracted on an electromagnetic generator of the electromagnetic heating smoking set when in use, and the electromagnetic base (1) is made of a magnetic conductive material; the downstream end of the heat conduction extending part (2) extends towards the interior of an aerosol generating base material of the aerosol generating product, and the heat conduction extending part (2) is made of a heat conduction material. The electromagnetic heating component is provided with the heat conduction extending part (2) which is inserted into the aerosol generating base material, the electromagnetic base (1) can generate induction current to generate heat when making contact with the electromagnetic generator, heat is transmitted to the heat conduction extending part (2), and the heat conduction extending part (2) heats the aerosol generating base material to generate aerosol. According to the electromagnetic heating smoking set, the electromagnetic heating component can be detached and reused, the electromagnetic heating component can be cleaned conveniently due to detachment, and the defect that all the electromagnetic heating smoking set needs to be thrown away due to the fact that a certain part of the electromagnetic heating smoking set is damaged is avoided due to repeated use.

Owner:YUNNAN XIKE TECH CO LTD

A graphite evaporator and its automatic control system

ActiveCN105396304BIncrease profitImprove heat transfer efficiencyEvaporationSimultaneous control of multiple variablesPlate heat exchangerAutomatic control

The invention provides a graphite evaporator. The graphite evaporator comprises a housing, a waveform heat insulating layer is spread on an inner wall of the housing, a corrosion preventing composite layer is spread on an outer wall of the housing, and the housing is made from stainless steel; the upper part, the middle part and the lower part of the housing are separately provided with a loop of steam distributor, sides of each of the steam distributors at the upper part and the lower part of the housing are provided with steam inlets, a steam inlet passage is arranged at one side of the steam distributor in the middle part of the housing, automatic control systems are connected to the steam inlets, and a steam outlet is arranged above one side of the steam inlet at the upper part of the housing; several U-shaped grooves and lateral through holes are arranged at the outside of graphite heat exchange blocks, and places between every two layers of the graphite heat exchange blocks are sealed with fluororubber. The graphite evaporator has the advantages of improved steam utilization rate, enhanced corrosion resistance, high temperature resistance and high pressure resistance, prolonged service life, and excellent performance; automatic control is realized at the same time. The invention also comprises an automatic control system for controlling the graphite heat exchanger.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

A preparation method of graphene ceramic film for metallurgical nozzle

The invention provides a method for preparing a graphene ceramic membrane used in a metallurgical nozzle, comprising the following steps: (1) firstly prepare a heat conducting layer: mix graphite powder, graphene powder and binder, and evenly coat On the working surface of the long nozzle or submerged nozzle; (2) Then prepare the ceramic film protective layer: Al 2 o 3 、Si 3 N 4 , TiC, WC, binder, lubricant, dispersant, and water are evenly mixed and applied on the heat conducting layer prepared in step (1); (3) low-temperature calcination; (4) high-temperature calcination. The invention uses the high thermal conductivity of graphite and graphene to quickly disperse the thermal shock of molten steel in the entire long nozzle or submerged nozzle body, avoiding heat accumulation in the local area of the nozzle, so that all parts of the nozzle can maintain a stable and firm internal structure , there is no weak area, thus improving the working time of the nozzle as a whole.

Owner:JIANGSU TAIRUI REFRACTORY

Preparation method of carbon/carbon composite material thin-walled cylinder

PendingCN112457038AIncreased mechanical strength and longevityReduce energy consumptionBatch productionCarbon source

The invention provides a preparation method of a carbon / carbon composite material thin-walled cylinder, and is used for solving the problems of long period, low efficiency and low product strength ofa carbon / carbon composite cylinder preparation process in the prior art. The preparation method of the carbon / carbon composite material thin-walled cylinder comprises the steps: electrifying and heating a carbon fiber cylinder prefabricated body in a vacuum deposition chamber, and internally heating the cylinder, so as to enable the cylinder prefabricated body to be non-uniformly heated on cylinder walls with different radial wall thicknesses and have a temperature gradient; and introducing a deposition carbon source mixed gas into the vacuum deposition chamber, and carrying out uniform carburization in carbon fibers of the cylinder wall based on the temperature gradient to obtain the carbon / carbon composite material thin-walled cylinder with the density of 1.5-1.8 g / cm<3>. According to the invention, the positions with different thicknesses on the cylinder wall have uniform carburization amount, the mechanical strength is improved, the service life is prolonged, an external heat source is not needed to provide high temperature, the energy consumption is reduced, the production period is shortened, the production efficiency is improved, and batch production can be realized.

Owner:甘肃新西北碳素科技有限公司

Preparation method of graphene ceramic membrane for metallurgy nozzle

The invention provides a preparation method of a nozzle graphene refractory material, and the preparation method comprises the following steps: (1) firstly preparing a heat conducting layer, namely, mixing graphite powder, graphene powder and a binder, and uniformly coating the working surface of a long nozzle or a submerged nozzle with the mixture; (2) preparing a ceramic membrane protective layer, namely, evenly mixing Al2O3, SiN4, TiC, WC, a binder, a lubricant, a dispersant and water, and coating a heat conducting layer prepared in the step (1) with the mixture; (3) performing low-temperature calcination; (4) performing high temperature calcination. According to the invention, the high thermal conductivity of the graphite and the graphene is utilized to rapidly disperse the thermal shock of molten steel to the whole long nozzle or submerged nozzle body, so that the heat accumulation in a local area of the nozzle is avoided, and each part of the nozzle can maintain the stability andfirmness of the internal structure without the appearance of weak areas, and the working time of the nozzle as a whole is improved.

Owner:JIANGSU TAIRUI REFRACTORY

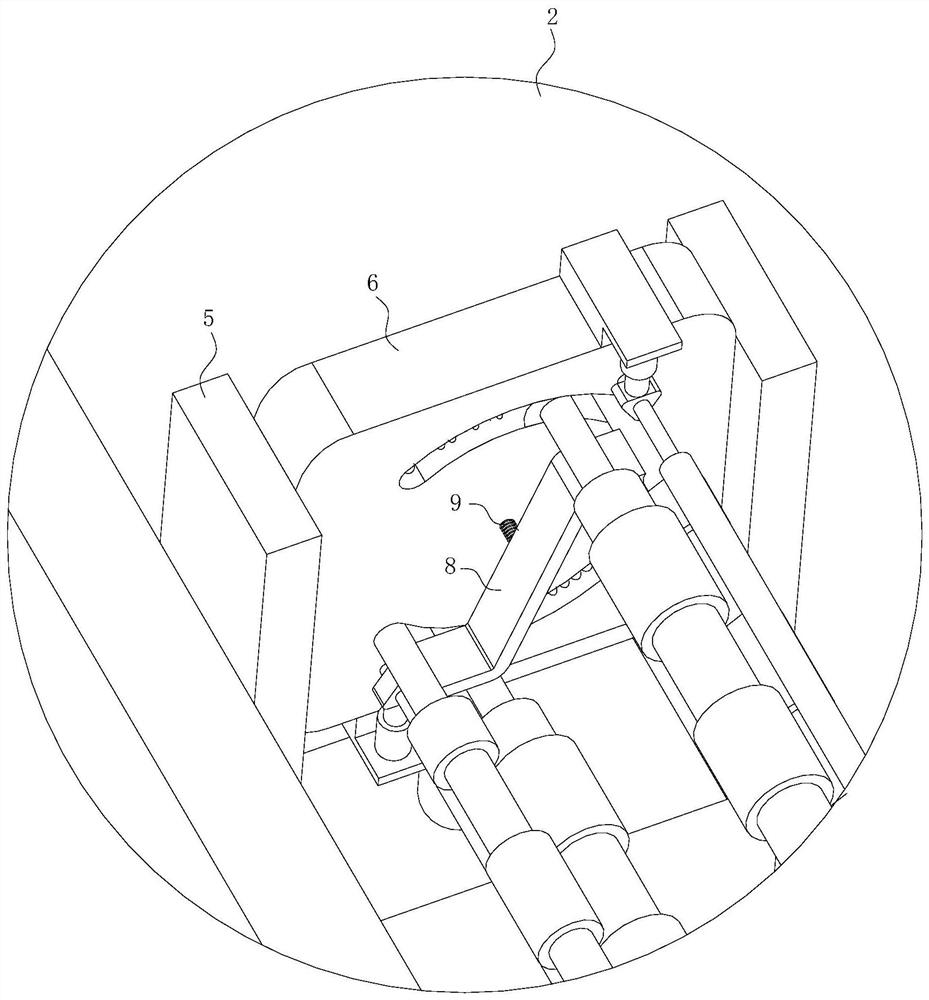

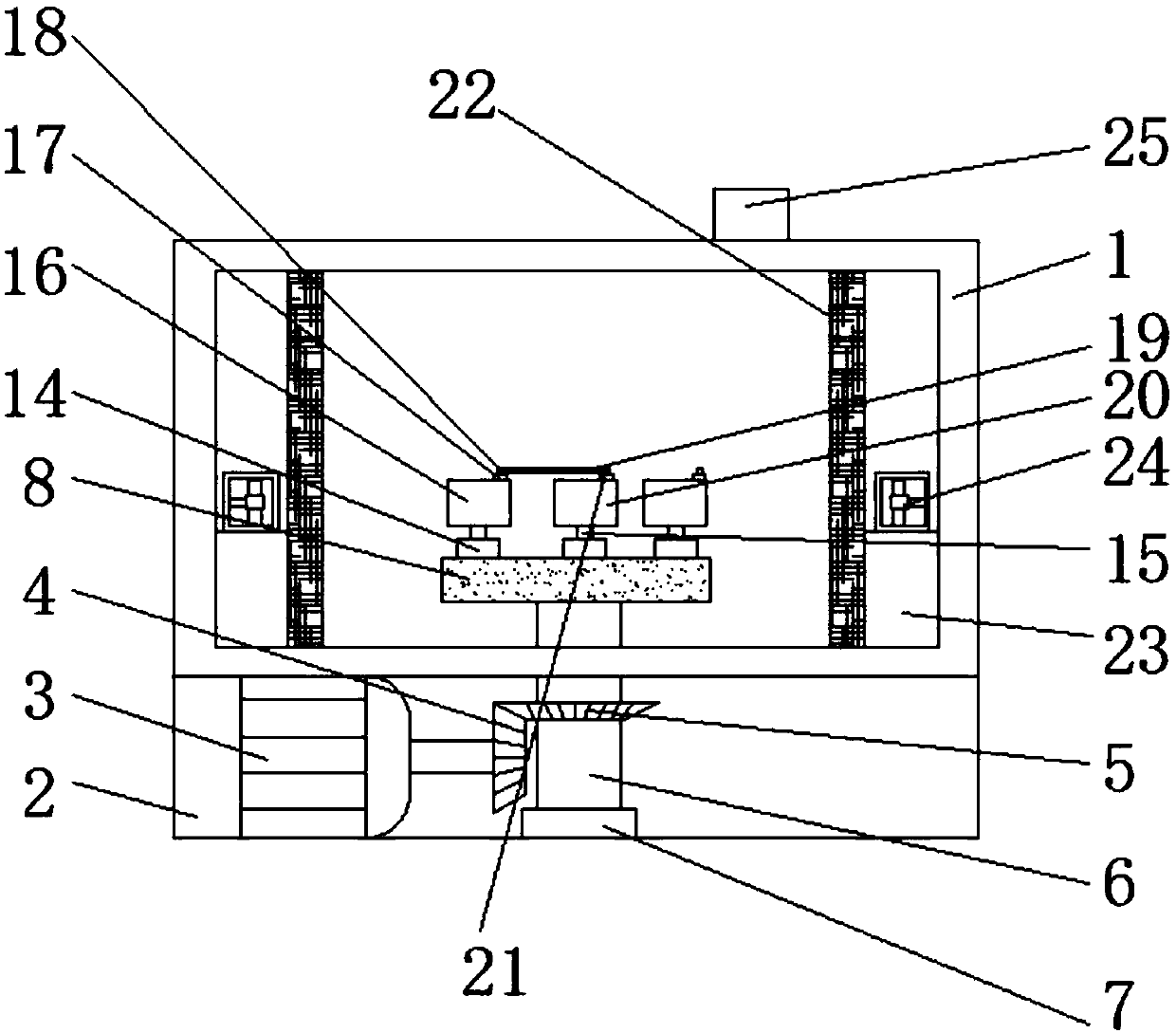

A bearing manufacturing device for forging machinery

ActiveCN109175206BEvenly heatedManufacturing rate declineForging press detailsForge furnacesRotational axisMachine

The invention relates to a bearing manufacturing device for a forging machine. The bearing manufacturing device for the forging machine comprises a forging table and a third manipulator; a first supporting column is fixed to the right side of the upper end of the forging table; a motor is arranged in the middle of the upper end of the forging table; a gas furnace is installed at the top end of thefirst supporting column; a rotary shaft is embedded in the middle of the lower of the interior of the gas furnace; the upper end of the rotary shaft is connected with a connection shaft; and fixed boards are fixed to two sides of the connection shaft. The bearing manufacturing device for the forging machine has the beneficial effects that through the fixed boards, bearing material sections can besupported, when the connection shaft rotates, the fixed boards are driven to rotate, the bearing material sections rotate in the gas furnace, and the bearing material sections make full contact withhigh-temperature heat in the gas furnace; and at the same time, the fixed boards are internally provided with net holes, the high-temperature heat at the bottom end permeates upwards, and the situation that the fixed boards at the bottom end block the high-temperature heat on the lower part and uneven distribution of the high-temperature heat in the gas furnace is caused is prevented.

Owner:TAIZHOU LONGDA TECH CO LTD

A kind of graphene refractory material preparation method for nozzle

The invention provides a method for preparing a graphene refractory material for a nozzle, comprising the following steps: (1) first preparing a heat conducting layer: mixing graphite powder, graphene powder, titanium carbide, tungsten carbide, and a binder , evenly coated on the working surface of the long nozzle or submerged nozzle (2) and then prepare the ceramic film protective layer: Al 2 o 3 、Si 3 N 4 , binder, lubricant, dispersant, and water are evenly mixed and applied on the heat conducting layer prepared in step (1); (3) low-temperature calcination; (4) high-temperature calcination. The invention uses the high thermal conductivity of graphite and graphene to quickly disperse the thermal shock of molten steel in the entire long nozzle or submerged nozzle body, avoiding heat accumulation in the local area of the nozzle, so that all parts of the nozzle can maintain a stable and firm internal structure , there is no weak area, thus improving the working time of the nozzle as a whole.

Owner:JIANGSU TAIRUI REFRACTORY

A test method for variable focus laser heating thermal fatigue test bench

ActiveCN103063424BUneven heatingControl the degree of thermal fatigueMachine part testingThermal fatigueThermodynamics

The invention discloses a variable-focus laser-heating thermal fatigue test bed which comprises a variable-focus laser device and a workbench, wherein the variable-focus laser device is installed above the workbench, the variable-focus laser device includes a cross arm which can be adjusted up and down, the cross arm is installed on a stand column, a laser transmitting aperture is fixedly formed in the right end of the cross arm, the lower end of the laser transmitting aperture is connected with a focus lens, and the stand column is fixed on a base body of the workbench. According to the variable-focus laser-heating thermal fatigue test bed with the way adopted, local heating measurement can be conducted according to specimens of different types. The size of a heating range can be controlled by means of adjusting the focus of the lens. Moreover, the specimens can be unequally heated, so that simulation can accord with actual heating conditions, and the thermal fatigue degree of the specimens can be measured out.

Owner:SUZHOU VOCATIONAL UNIV

Oven for sheet metal part paint baking

InactiveCN110947598AUniform temperatureEvenly heatedPretreated surfacesCoatingsRotational axisElectric machine

The invention belongs to the technical field of paint baking equipment, particularly relates to an oven for sheet metal part paint baking, and aims to solve the problem that in the paint baking process, by means of an existing oven, heating is prone to be uneven, and the colors of paint baking are different, so that the whole paint baking technology is influenced. According to the scheme, the ovencomprises a shell, wherein a metal plate is fixedly installed inside the shell, a plurality of electric heating plates are fixedly installed on one side of the metal plate, a motor chamber is fixedlyinstalled on one side of the shell, a motor is fixedly installed in the motor chamber, a rotary supporting plate is rotationally installed on the inner wall of the bottom of the shell, the inner walls of one sides, close to each other, of the motor chamber and the shell are provided with the same first rotating hole, and a first rotating shaft is rotationally installed in the rotating hole. According to the oven, the motor and fan blades cooperate with the rotary supporting plate, so that the situation that a sheet metal part is heated unevenly in the paint baking process, and the colors of paint baking are different is avoided.

Owner:武汉欣顺达金属激光制品有限公司

A graphite evaporator for evaporation and concentration and its automatic control system

ActiveCN105396303BIncrease profitImprove heat transfer efficiencyEvaporationSimultaneous control of multiple variablesAutomatic controlEvaporation

The invention provides a graphite evaporator for concentration by evaporation. The graphite evaporator comprises a housing, a waveform heat insulating layer is spread on an inner wall of the housing, a corrosion preventing composite layer is spread on an outer wall of the housing, and the housing is made from stainless steel; the upper part, the middle part and the lower part of the housing are separately provided with a loop of steam distributor, sides of each of the steam distributors at the upper part and the lower part of the housing are provided with steam inlets, a steam inlet passage is arranged at one side of the steam distributor in the middle part of the housing, automatic control systems are connected to the steam inlets, and a steam outlet is arranged above one side of the steam inlet at the upper part of the housing; several U-shaped grooves and lateral through holes are arranged at the outside of graphite heat exchange blocks, and places between every two layers of the graphite heat exchange blocks are sealed with fluororubber. The graphite evaporator has the advantages of improved steam utilization rate, enhanced corrosion resistance, high temperature resistance and high pressure resistance, prolonged service life, and excellent performance; and automatic control is realized at the same time. The invention also comprises an automatic control system for controlling the graphite heat exchanger for concentration by evaporation.

Owner:PINGDINGSHAN XINRUIDA NEW MATERIAL TECH CO LTD

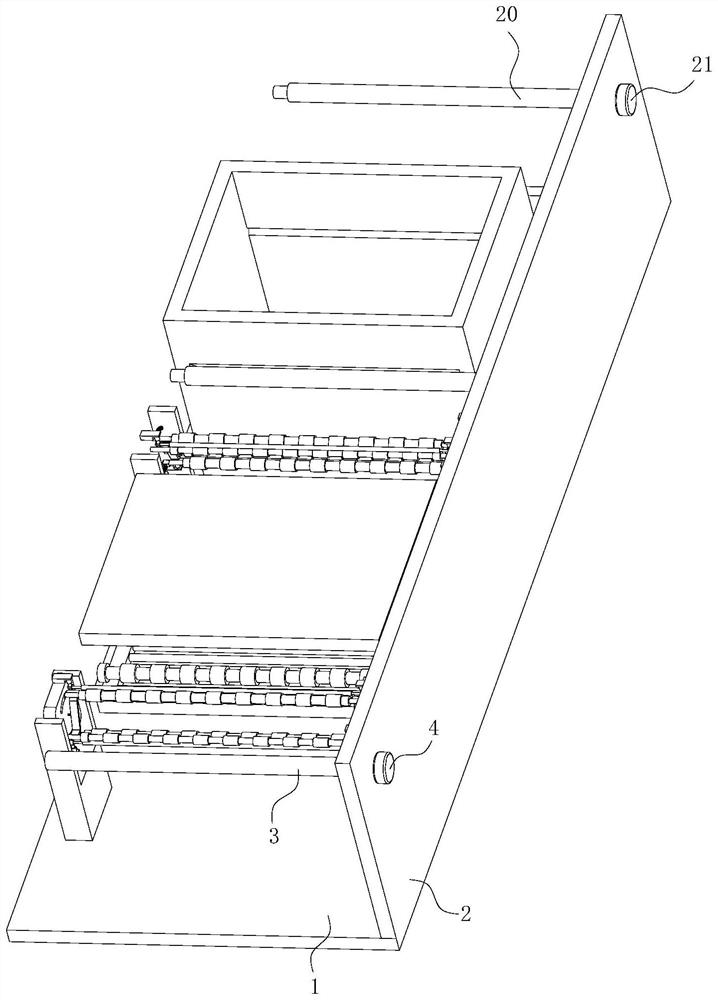

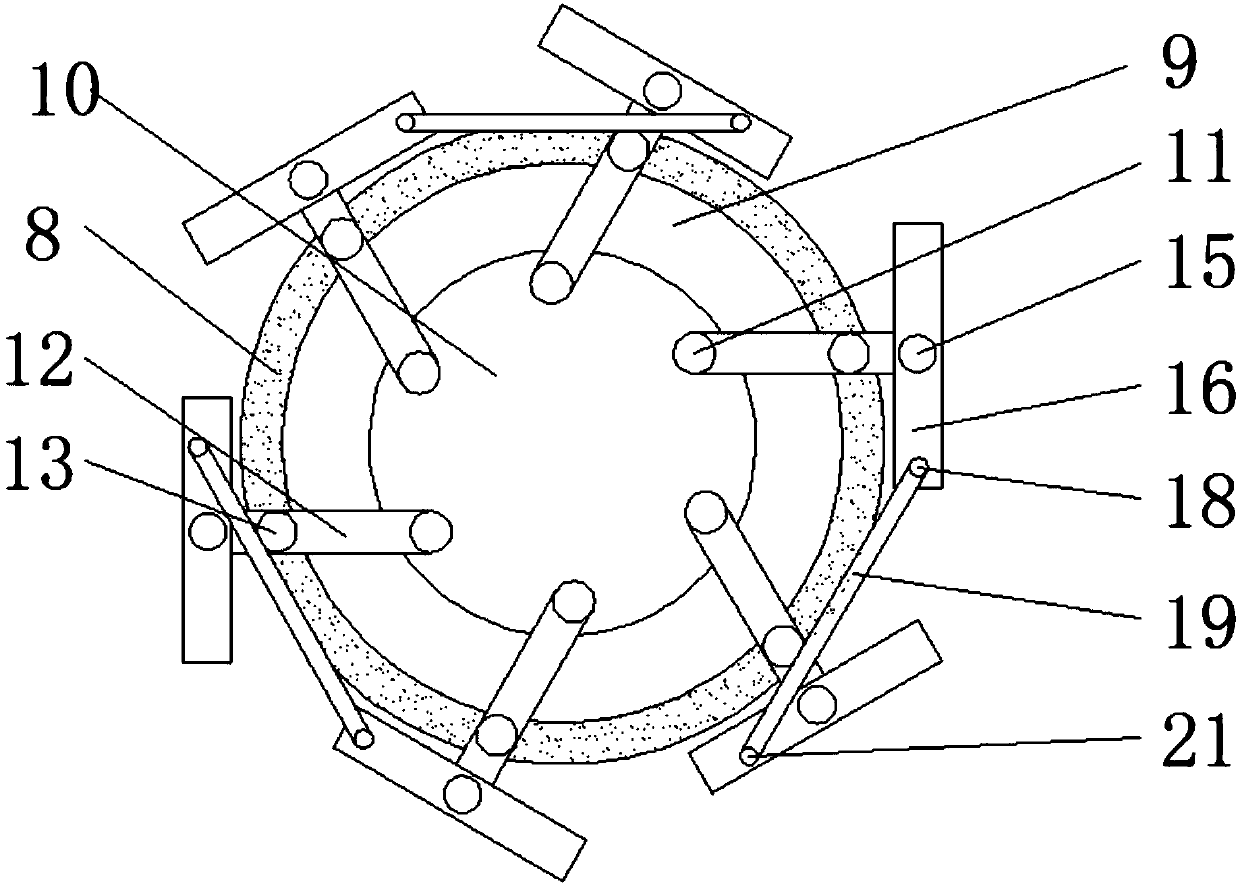

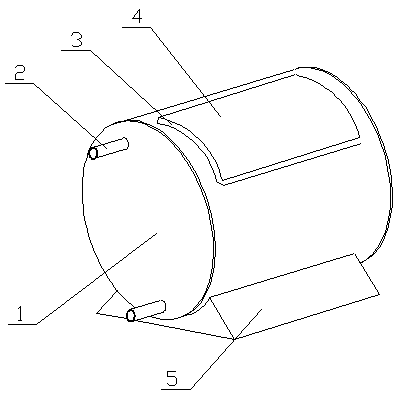

Stainless steel electrode drying device for building construction

PendingCN107824947AEvenly heatedImprove drying effectWelding accessoriesStainless steel electrodeEngineering

The invention relates to a stainless steel electrode drying device for building construction and discloses a device which conducts omnibearing drying on each electrode by tiling the different marks ofelectrodes and combining eccentric rotation. The stainless steel electrode drying device for building construction is characterized in that a main cabin is transversely arranged on a base, the main cabin is an airtight cylindrical container, a cabin door is arranged on the main cabin and located on the upper side of one side of the main cabin, a circle of sealing cushion is arranged between the cabin door and the main cabin, a heating coil is arranged on the inner wall of the main cabin, each of the two ends of the heating coil penetrates one end of the main cabin, the two ends of the heatingcoil are provided with one-way valves, the surface of one side of the heating coil is provided with sector-shaped heat dissipation fins, the heating coil is turned back along the interior of the maincabin in the axial direction, a cylindrical heating area is formed, a sealing cover plate is arranged in the main cabin and is close to the other end of the main cabin, the sealing cover plate and the main cabin are connected and fixed through spot welding, welding spots are distributed at equal intervals, and the sealing cover plate divides the main cabin into two cavities which are unequal in size.

Owner:徐州新南湖科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com