High-magnetic performance NdFeB magnet capable of cyclically utilizing waste material and fabrication method of NdFeB magnet

A technology of NdFeB magnets, which is applied in the field of high-magnetic NdFeB magnets and their preparation, and can solve problems such as uneven distribution of NdFeB magnet components, uneven magnetic force distribution of NdFeB magnets, and uneven heating of blanks. , to achieve the effect of balanced quality, reasonable structure and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

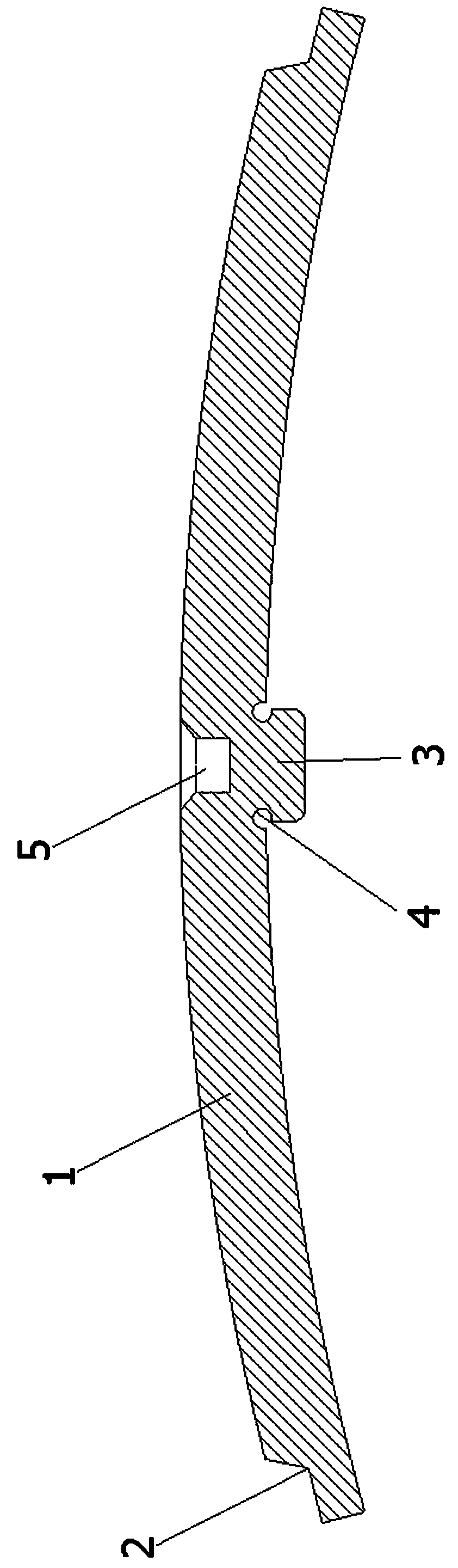

[0026] Example: In this example, a high-magnetic-performance neodymium iron boron magnet recycled from waste materials. The composition of the neodymium iron boron magnet is: 127.66kg of N52HT, 259.19kg of old SH material, and 13.15kg of Pr-Nd, such as figure 1 , The neodymium iron boron magnet includes an arc-shaped magnet body 1, two ends of the magnet body are respectively provided with a notch 2, the middle of the magnet body is provided with a protrusion 3, and both ends of the protrusion are provided with arc-shaped grooves 4 at the roots. A mounting cup hole 5 is opened in the middle of the magnet body, and the mounting cup hole is located above the bump 3.

[0027] A preparation method of high-magnetic-performance neodymium iron boron magnets recycled from waste materials, and the steps are as follows:

[0028] a. Put the powders of each component of claim 1 into a vacuum quick-setting furnace according to the ratio for casting, so that the thickness of the casting is 0.16-0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com