Heater block of rapid thermal process apparatus

A rapid heat treatment and heater technology, applied in the direction of heating elements, ohmic resistance heating devices, ohmic resistance heating parts, etc., can solve problems such as difficult to rearrange heating lamps, uneven heating of substrates, difficult to maintain and repair heater units, etc. , to achieve easy maintenance and repair, prevent heat damage, and prevent uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. The following embodiments are only described for a better understanding of the present invention. Those skilled in the art should understand that without departing from the scope and spirit of the present invention disclosed in the appended claims, they can Various improvements are made to the embodiment.

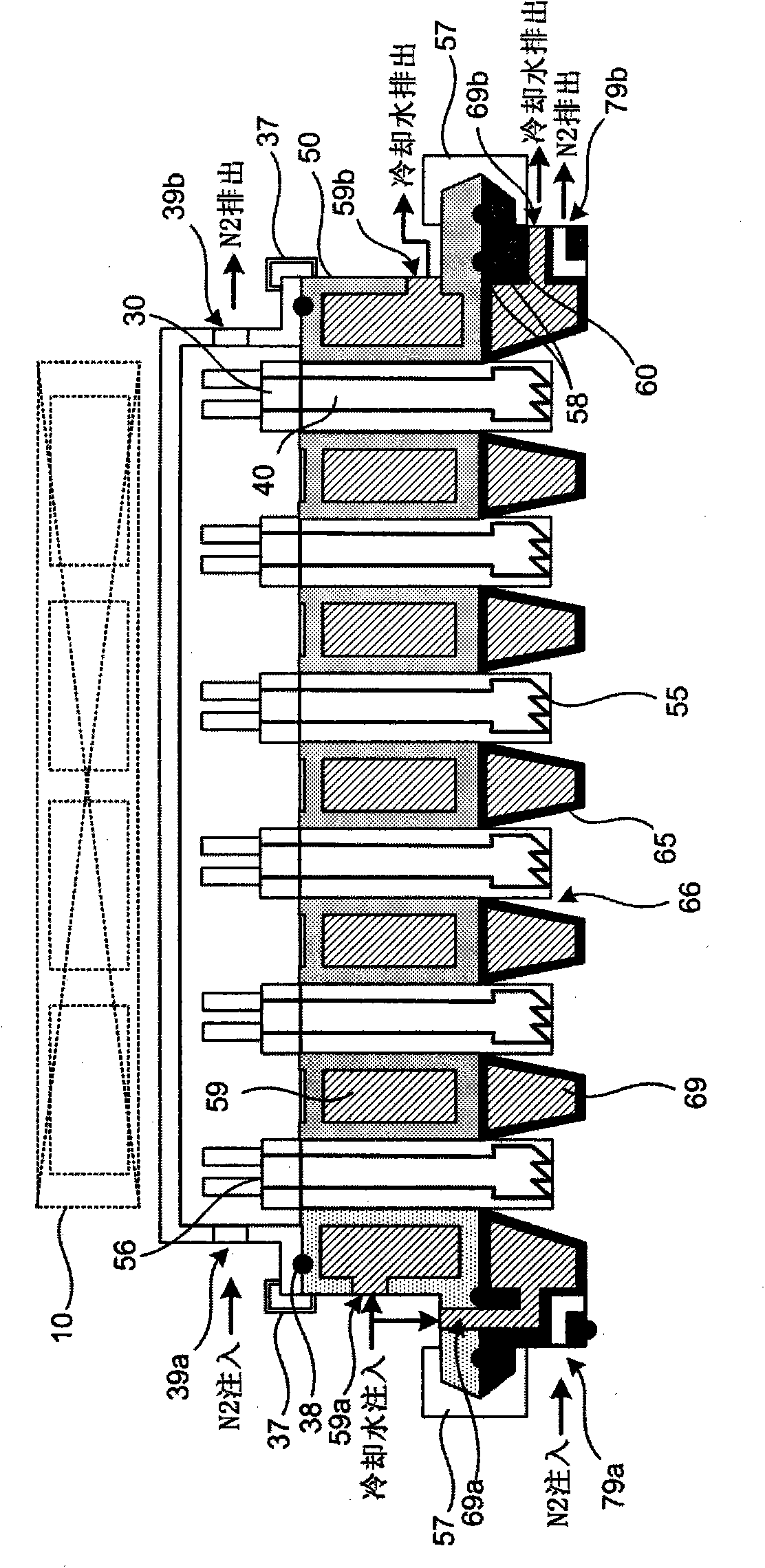

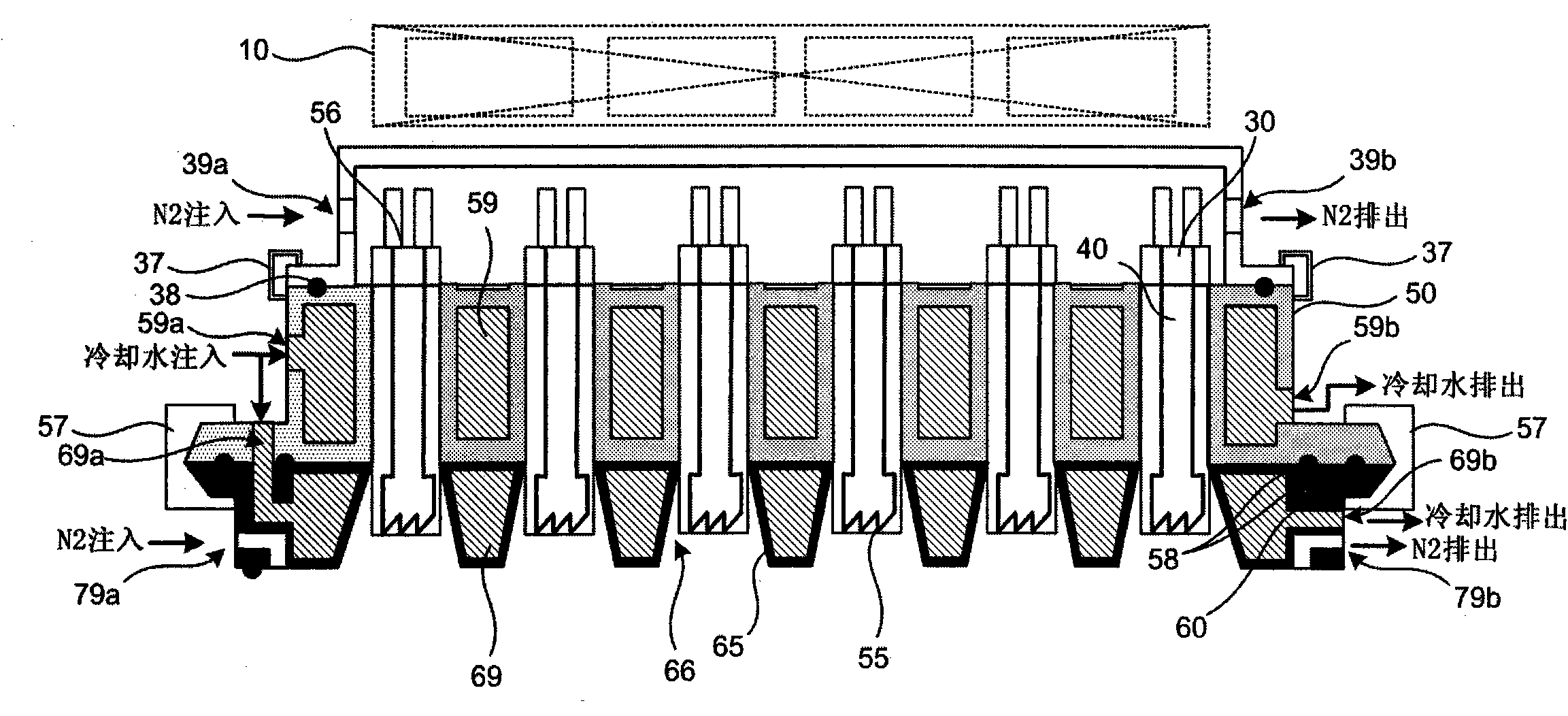

[0018] figure 1 It is a schematic diagram illustrating the heater unit of the rapid thermal processing apparatus according to the present invention. Reference figure 1 The heater unit of the present invention includes a lamp cover 50, a socket cover 30 and a reflector cover 60 that are detachably connected.

[0019] The lamp cover 50 is formed in a flat plate shape, and a plurality of lamp insertion holes are formed vertically through the lamp cover 50. The socket cover 30 covers the upper surface of the lamp cover 50.

[0020] With the O-ring 38...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com