Oven for sheet metal part paint baking

A technology for sheet metal parts and baking paint, which is applied to the device for coating liquid on the surface, pretreatment surface, coating, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

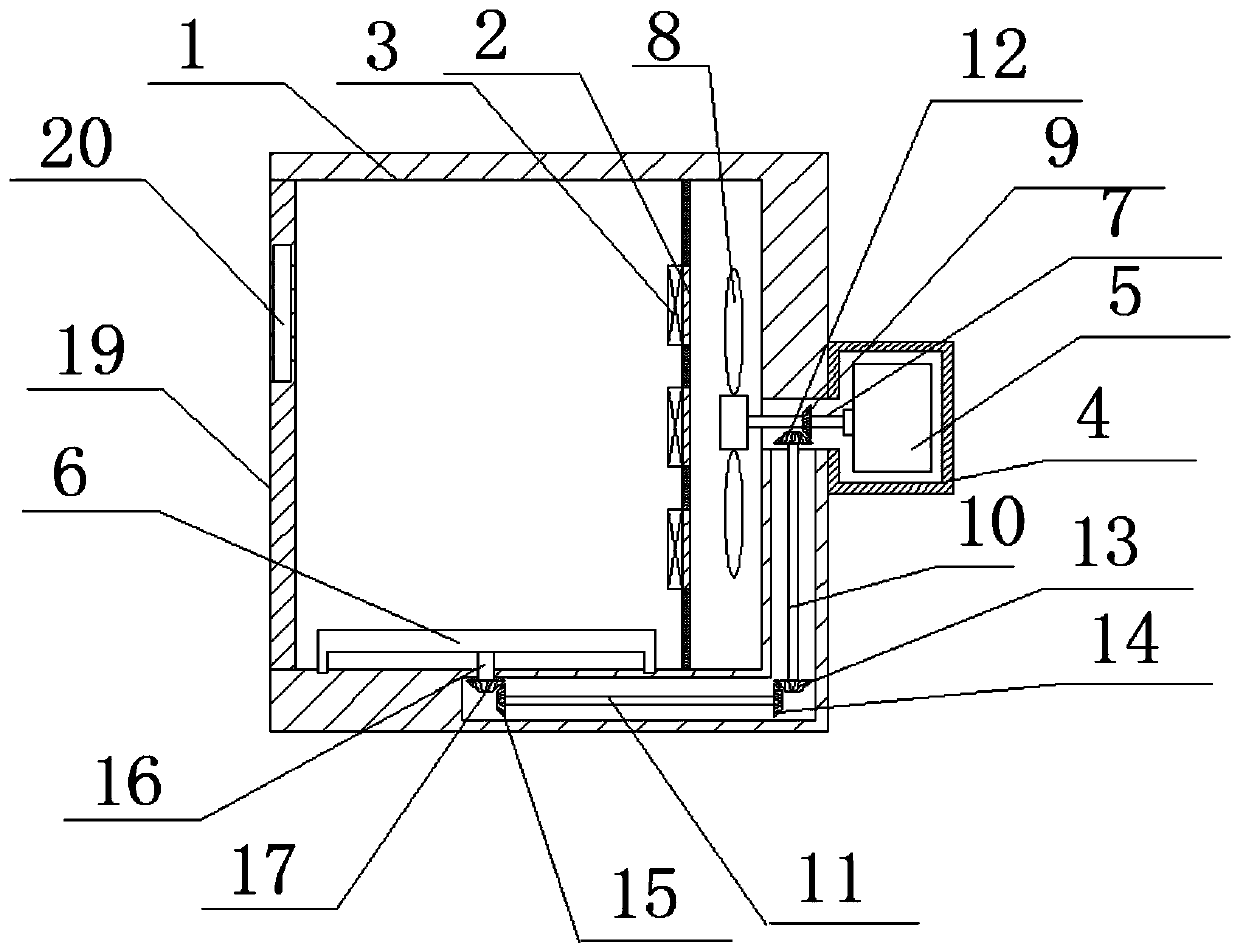

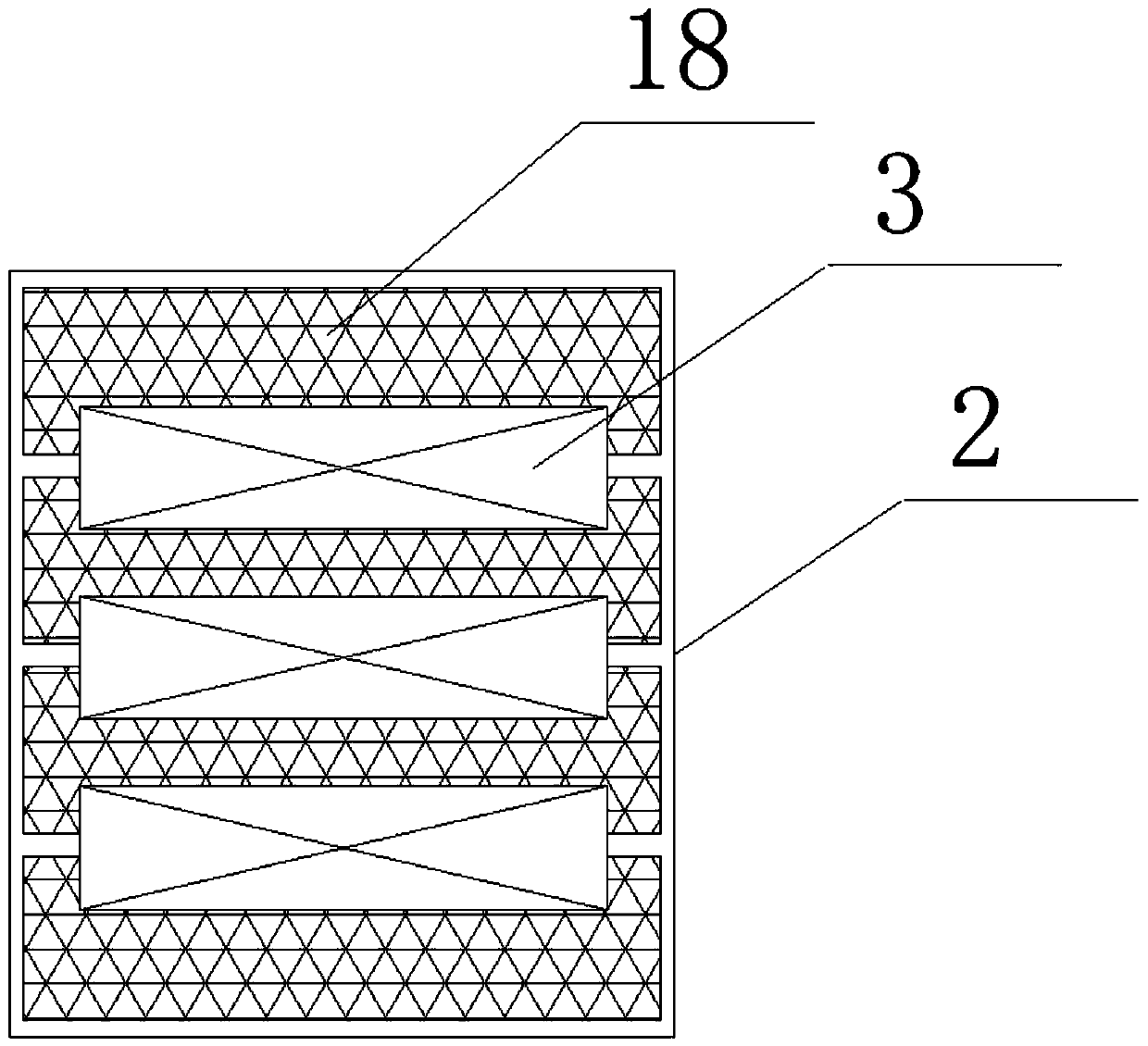

[0021] refer to Figure 1-3 , an oven for baking paint on sheet metal parts, comprising a housing 1, a metal plate 2 is fixedly installed inside the housing 1, a plurality of electric heating plates 3 are fixedly installed on one side of the metal plate 2, and a plurality of electric heating plates 3 are fixedly installed on one side of the housing 1. A motor room 4 is fixedly installed, and a motor 5 is fixedly installed in the motor room 4, and a rotating supporting plate 6 is installed on the bottom inner wall of the housing 1, and the same inner wall is provided on the inner wall of the motor room 4 and the housing 1. The first rotating hole, the rotating hole is equipped with a first rotating shaft 7, one end of the first rotating shaft 7 extends into the motor chamber 4 and is fixedly connected with the output shaft of the motor 5, and the other end of the first rotating shaft 7 extends to the shell The fan blade 8 is fixedly connected to the body 1, the first bevel gear...

Embodiment 2

[0027] refer to Figure 1-3 , an oven for painting sheet metal parts, comprising a shell 1, the inside of the shell 1 is fixedly installed with a metal plate 2 by welding, one side of the metal plate 2 is fixed with a plurality of electric heating plates 3, the shell One side of 1 is fixed with a motor chamber 4 by bolts, and a motor 5 is installed in the motor chamber 4 by bolts, and a rotating supporting plate 6 is installed on the bottom inner wall of the housing 1, and the motor chamber 4 and the housing 1 are close to each other. One side of the inner wall is provided with the same first rotating hole, and a first rotating shaft 7 is installed in the rotating hole. One end of the first rotating shaft 7 extends into the motor chamber 4 and is fixedly connected with the output shaft of the motor 5 by welding. The other end of a rotating shaft 7 extends into the casing 1 and is fixedly connected with a fan blade 8 through welding. The outer side of the first rotating shaft 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com