Stainless steel electrode drying device for building construction

A technology of building construction and drying device, applied in welding accessories and other directions, can solve the problems of large difference in drying effect, worsening effect of drug skin, worsening quality of welding position, etc., and achieve the effect of improving drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

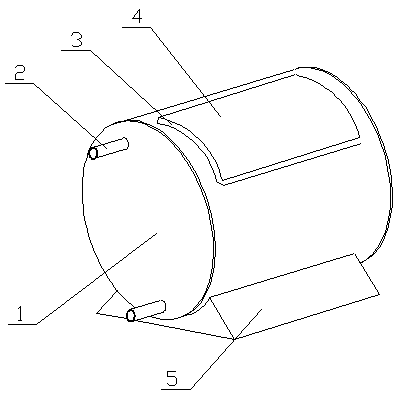

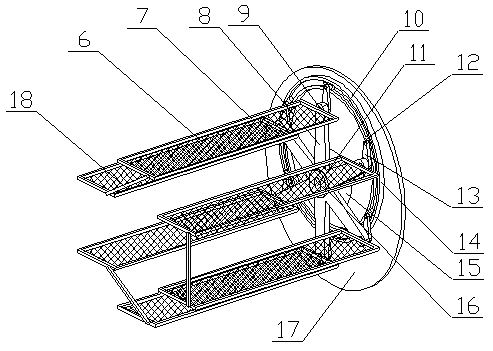

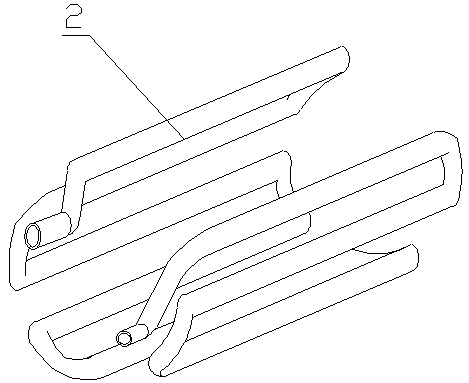

[0031] A stainless steel welding rod drying device for building construction in the present invention is realized in this way. When in use, heat conduction oil is injected into the heating coil (2), and then two points of the heating coil (2) are connected to the circuit, so that the heating coil (2) Heating to heat the internal heat transfer oil to keep the temperature of the heating coil (2) warm, then open the hatch (4), and spread the welding rods layer by layer on the rotary frame (7). The welding rods are placed on the same revolving frame (7), and the adjacent two layers are separated by sponges. After the welding rods on each revolving frame (7) are flattened, close the hatch (4), and the power shaft ( 11) Drive the drive plate (16) to rotate, drive the fan-shaped slider (12) to rotate through the ring guide rail through the connecting arm (13), because the radius of gyration of the drive arm (8) is the same as that of the fan-shaped slider (12), Simultaneously, the ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com