Boiler overheater

A superheater and superheater tube technology, which is used in steam superheating, lighting and heating equipment, steam generation, etc., can solve problems such as inability to flexibly use other boilers, incomplete dehydration of saturated steam, and different superheater temperatures, so as to avoid heating The effect of unevenness, improving temperature utilization, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the accompanying drawings.

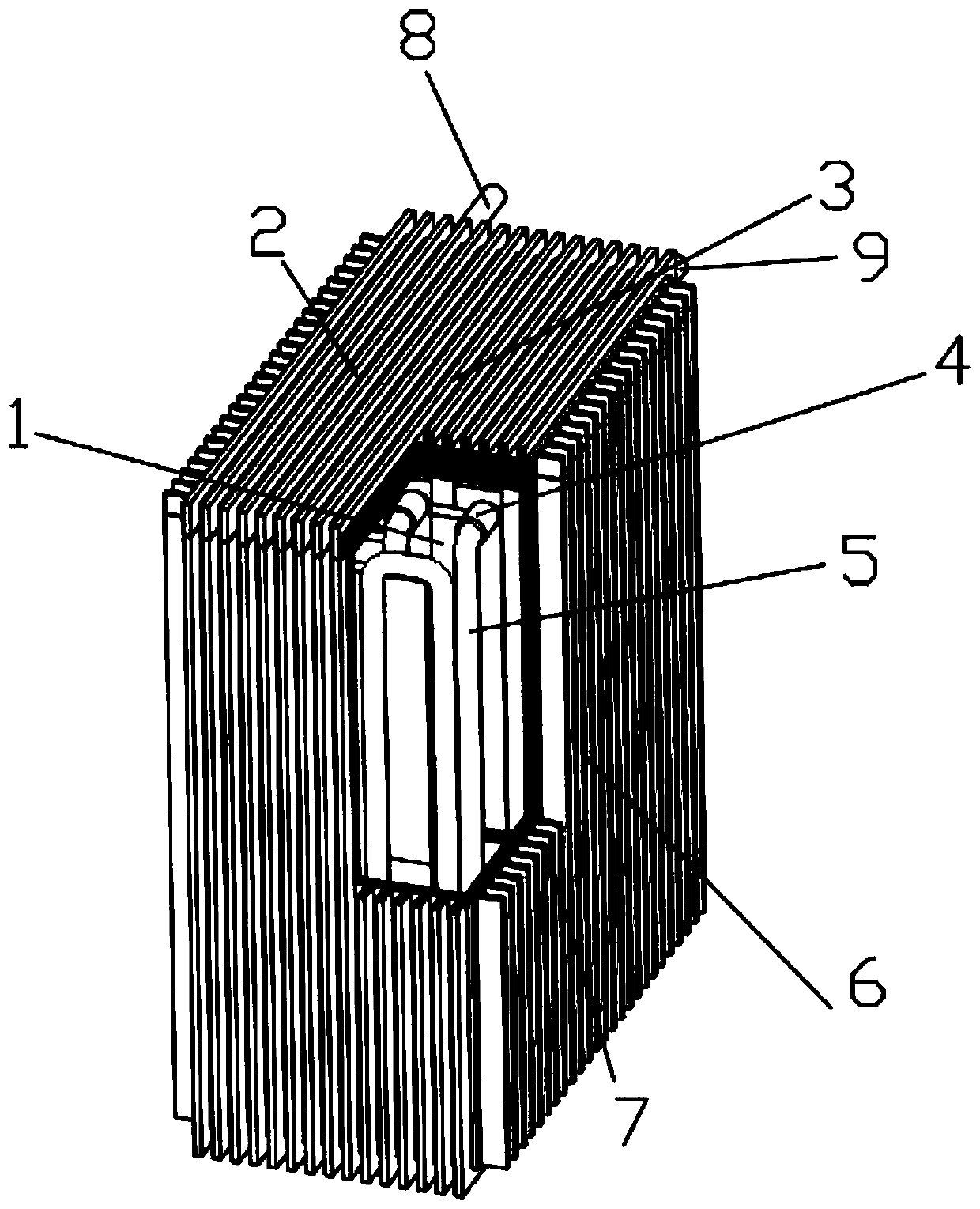

[0022] see Figure 1-4 As shown, a boiler superheater includes an internal heating plate 1, an upper cover 2, vertical heat conduction fins 3, connection and disassembly joints 4, superheater tubes 5, a shell 6, side heat conduction fins 7, and saturated steam input pipes 8 And superheated steam output pipeline 9.

[0023] The upper cover 2 is arranged on the upper end of the shell 6, the outer shell 6 is provided with side heat conduction fins 7, the lower end of the shell 6 is provided with vertical heat conduction fins 3, the side of the upper cover 2 is provided with side heat conduction fins 7, and the upper end of the upper cover 2 is provided with vertical heat conduction fins 3. Straight thermal fins3.

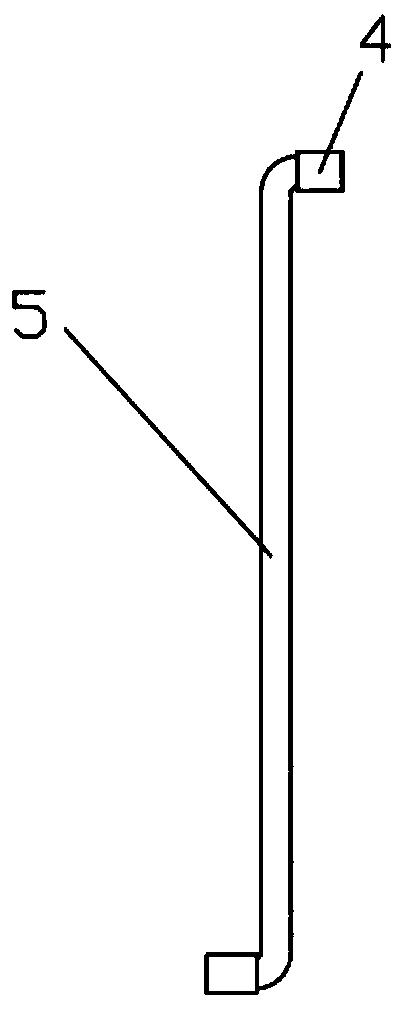

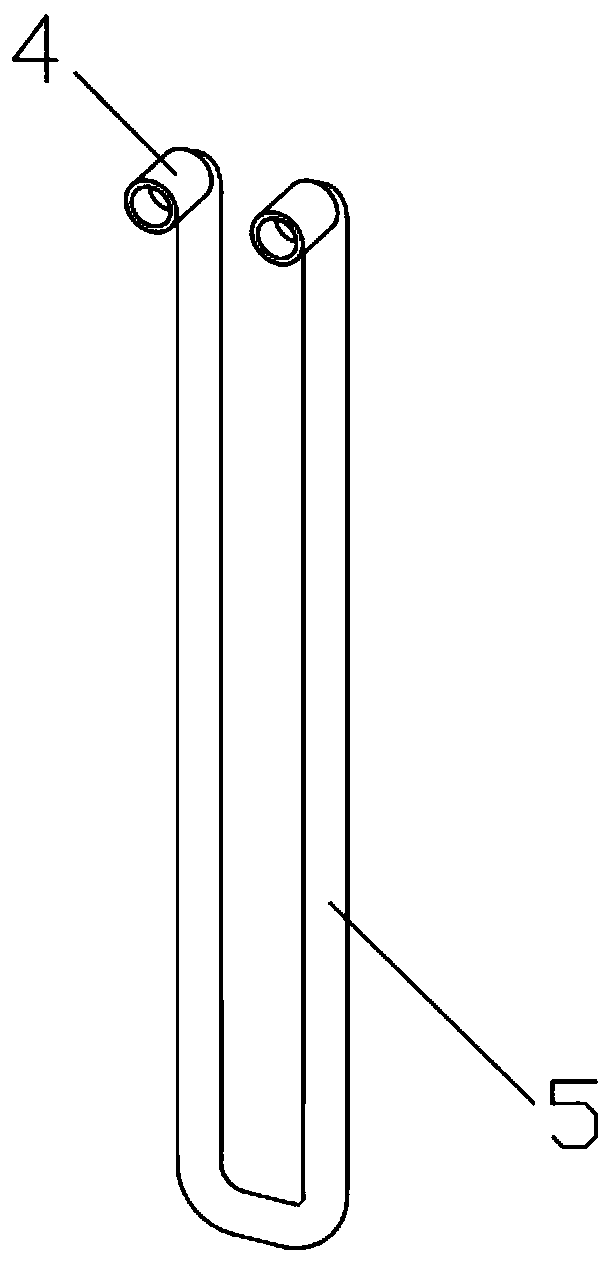

[0024] The superheater tube 5 is arranged inside the shell 6, and the two ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com