High-temperature carbonization treatment device for bamboo wood toys

A carbonization device and high-temperature carbonization technology, applied in the direction of charcoal burning/combustion, etc., can solve the problems affecting the quality of carbonization of bamboo and wood toys, high heating temperature, uneven heating of bamboo and wood toys, etc., to improve processing quality and increase contact area, to avoid the effect of being too dry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

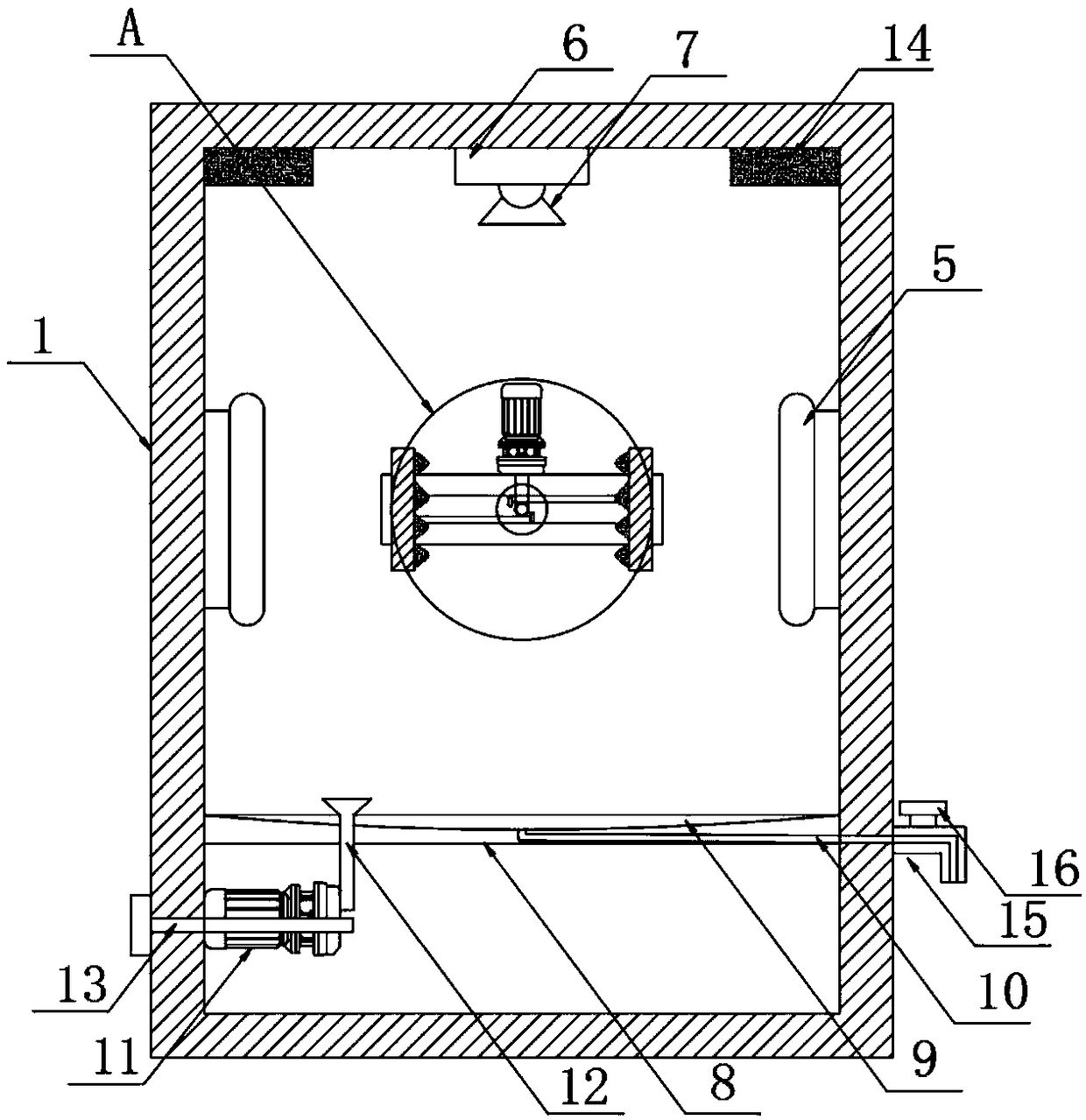

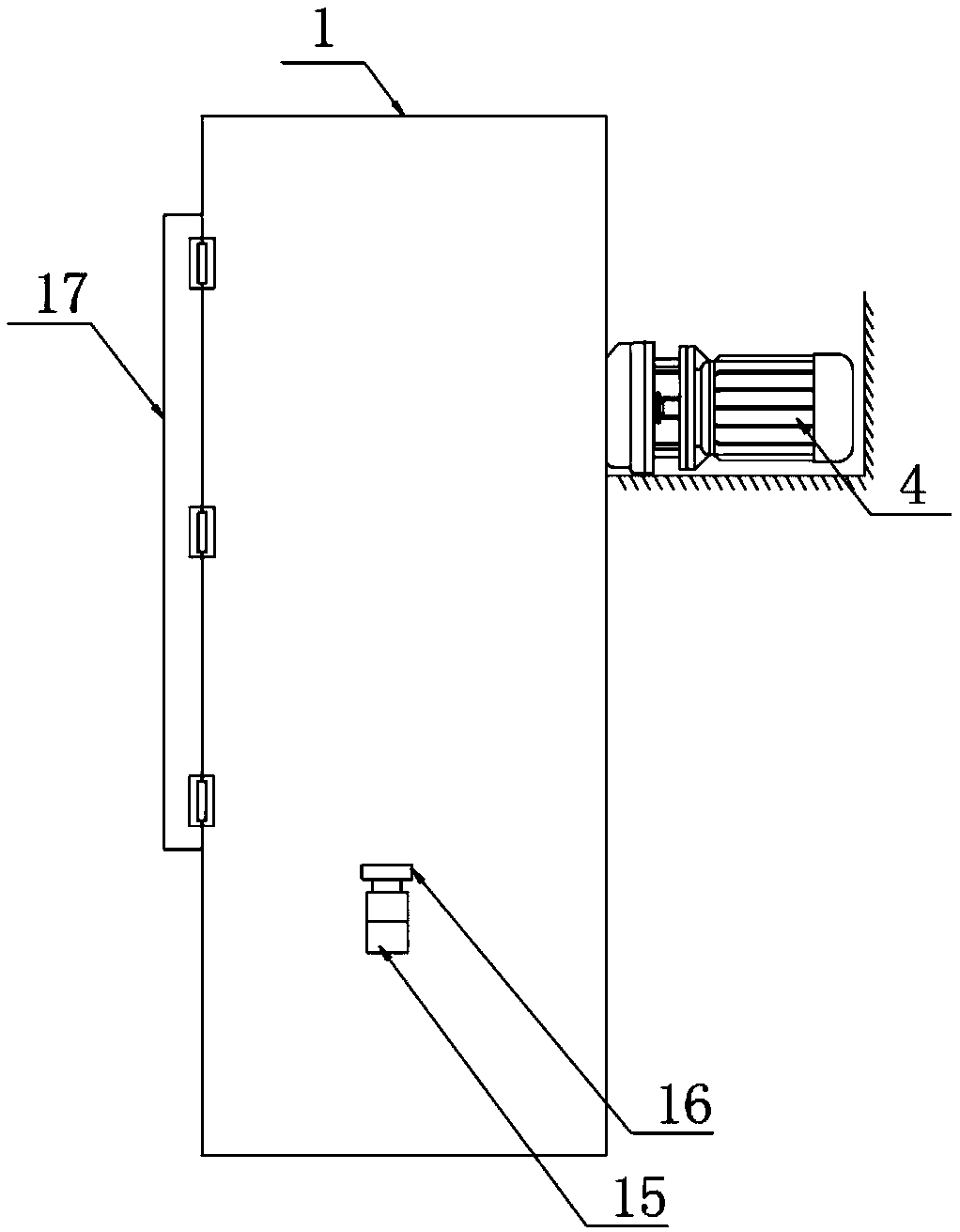

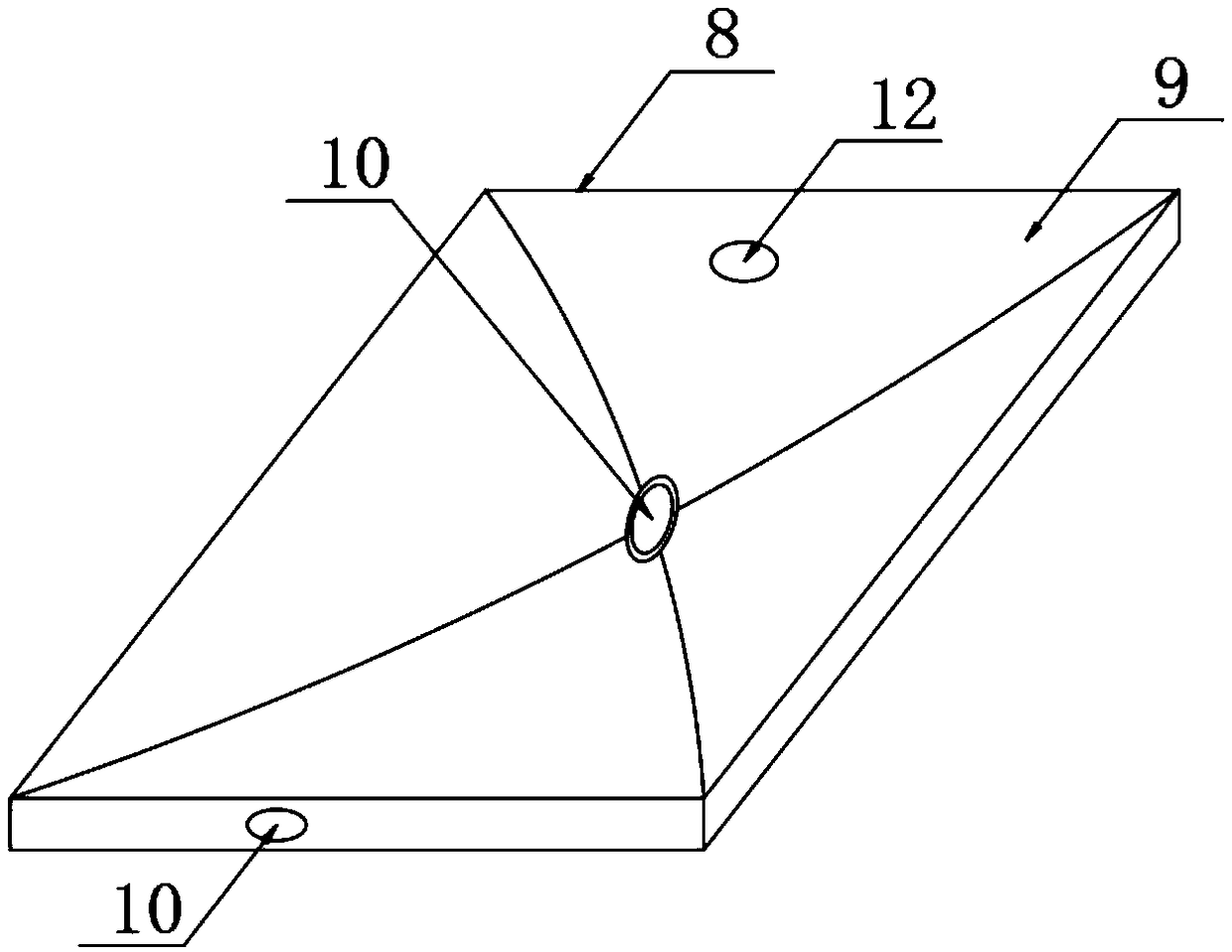

[0023] according to Figure 1-4 A bamboo and wood toy high-temperature carbonization treatment device shown includes a carbonization device main body 1, a clamping device 2 is arranged inside the carbonization device main body 1, and a rotating shaft 3 is fixedly arranged on one side of the clamping device 2, and the rotating shaft 3. One end runs through the side wall of the main body 1 of the carbonization device and extends to one side of the outer wall of the main body 1 of the carbonization device. A first rotating motor 4 is fixedly installed on one side of the outer wall of the main body 1 of the carbonization device. The output end of the first rotating motor 4 is connected to the The input end of the rotating shaft 3 is connected, the two sides of the clamping device 2 are provided with high-temperature heating lamps 5, and the high-temperature heating lamps 5 are fixedly arranged on the side wall of the inner cavity of the main body of the carbonization device 1, and ...

Embodiment 2

[0026] The difference with embodiment 1 is:

[0027] The clamping device 2 includes a connecting plate 21 and a clamping plate 22, the clamping plate 22 is arranged on both sides of the connecting plate 21, a groove 23 is provided on one side of the connecting plate 21, and a groove 23 is arranged on one side of the groove 23. Extending to the inner cavity of the connecting plate 21, a transmission gear 24 is movable in the groove 23, and a gear plate 25 is arranged on both sides of the transmission gear 24, and the gear plates 25 on both sides are meshed with the transmission gear 24. And the gear plate 25 is arranged in the groove 23, and the other end of the gear plate 25 is fixedly connected with one end of the clamping plate 22, which is conducive to clamping the bamboo and wood toys by using the clamping plates 22 on both sides;

[0028] The top of the connecting plate 21 is fixed with a second rotating motor 26, and the output end of the second rotating motor 26 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com