Preparation method of nozzle graphene refractory material

A technology of ene refractory material and graphene powder, which is applied in the field of preparation of graphene refractory material, can solve problems such as the inability to increase the working life of the nozzle, the lack of innovation in the principle of thermal shock resistance, and the prolongation of the thermal shock resistance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

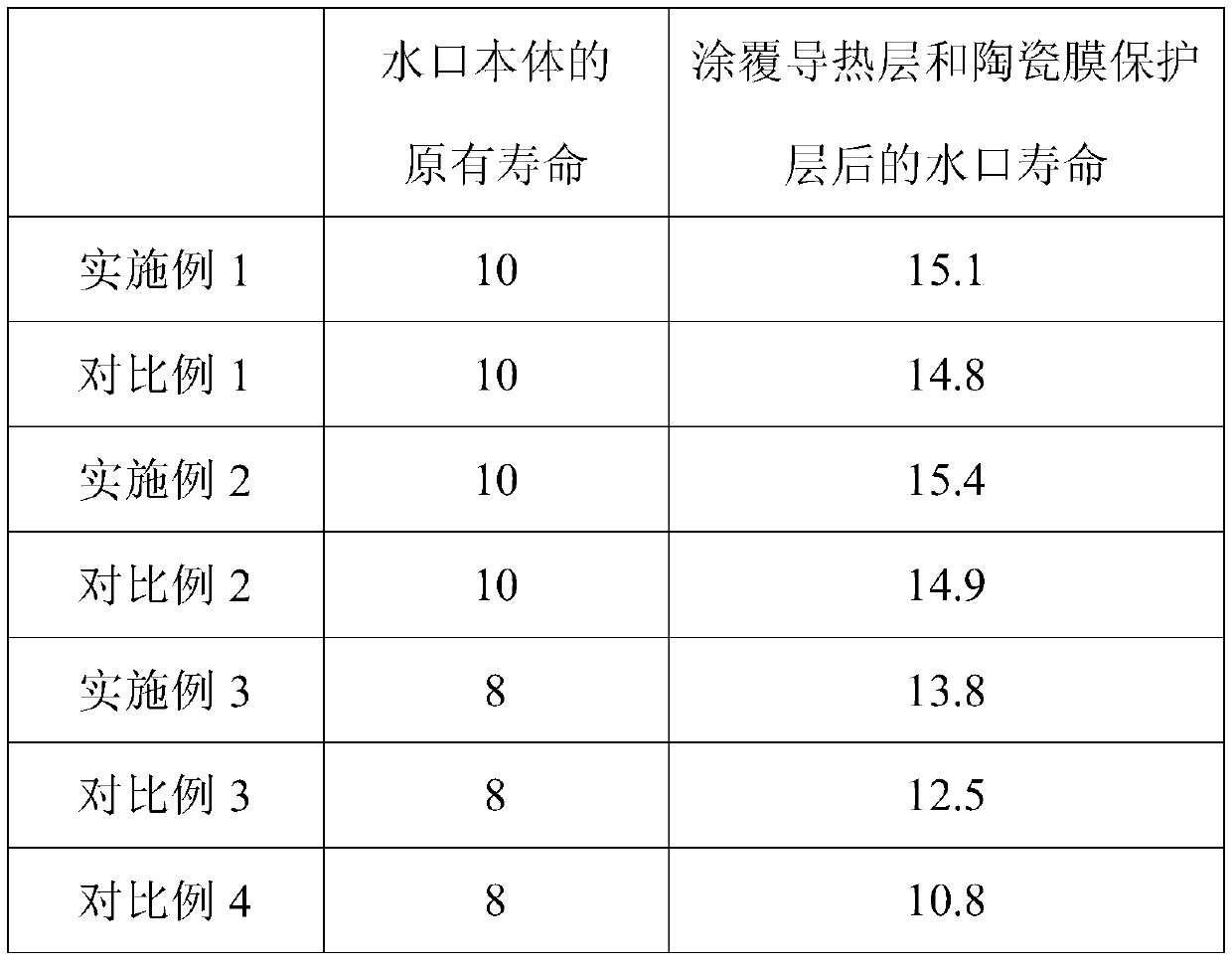

Examples

Embodiment 1

[0035] The preparation method of the graphene refractory material that the present embodiment provides for shroud comprises the following steps:

[0036] (1) First prepare the heat conducting layer: mix 100 parts of graphite powder, 5 parts of graphene powder, 10 parts of titanium carbide, 7 parts of tungsten carbide, and 15 parts of binder methyl cellulose, and then add the above raw materials 2 times the sum of water, use an ultrasonic disperser to evenly disperse all raw materials in water, and then evenly coat the working surface of the long nozzle with a coating thickness of 20 microns; dry at 150°C after coating; graphite powder Body and graphene powder were passed through a 300 mesh sieve before mixing.

[0037] (2) Then prepare the ceramic film protective layer: Al 2 o 3 : 40 parts; SiN 4 : 10 parts; Binder methylcellulose: 3 parts; Lubricant liquid paraffin: 0.5 part; Dispersant terpineol: 0.5 part; Water: 15 parts Mix evenly and apply to the heat conducting layer ...

Embodiment 2

[0041] The preparation method of the graphene refractory material that the present embodiment provides for shroud comprises the following steps:

[0042] (1) First prepare the heat conduction layer: mix 100 parts of graphite powder, 6 parts of graphene powder, 11 parts of titanium carbide, 8 parts of tungsten carbide, and 18 parts of binder hydroxypropyl methylcellulose, and then add mass Water that is 2.5 times the sum of the above raw materials, use an ultrasonic disperser to evenly disperse all the raw materials in water, and then evenly coat the working surface of the long nozzle with a coating thickness of 50 microns; dry at 160°C after coating ; The graphite powder and the graphene powder are respectively passed through a 200-mesh sieve before mixing.

[0043] (2) Then prepare the ceramic film protective layer: Al 2 o 3 : 45 parts; SiN 4 : 12 parts; binder hydroxypropyl methylcellulose: 4 parts; lubricant corn oil: 0.8 part; dispersant triethanolamine: 1 part; On the...

Embodiment 3

[0047] The preparation method for the graphene refractory material that the present embodiment provides for submerged nozzle comprises the following steps:

[0048] (1) First prepare the heat conducting layer: mix 100 parts of graphite powder, 7 parts of graphene powder, 12 parts of titanium carbide, 9 parts of tungsten carbide, and 20 parts of binder methyl cellulose, and then add one of the above raw materials and 3 times of water, use an ultrasonic disperser to evenly disperse all raw materials in water, and then evenly coat on the working surface of the submerged nozzle with a coating thickness of 30 microns; dry at 180°C after coating; graphite powder Body and graphene powder were passed through a 200 mesh sieve before mixing.

[0049] (2) Then prepare the ceramic film protective layer: Al 2 o 3 : 50 parts; SiN 4 : 15 parts; binder hydroxypropyl methylcellulose: 5 parts; lubricant liquid paraffin: 1 part; dispersant terpineol: 2 parts; water: 20 parts, mixed evenly and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com