Hydraulic height-adjustable turning tool

A hydraulic and high-level technology, applied in the direction of tools for lathes, turning equipment, accessories of tool holders, etc., can solve the problems of cutting tools, lower actual center height of installed tools, poor flatness of gaskets, etc., to achieve practical Strong and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

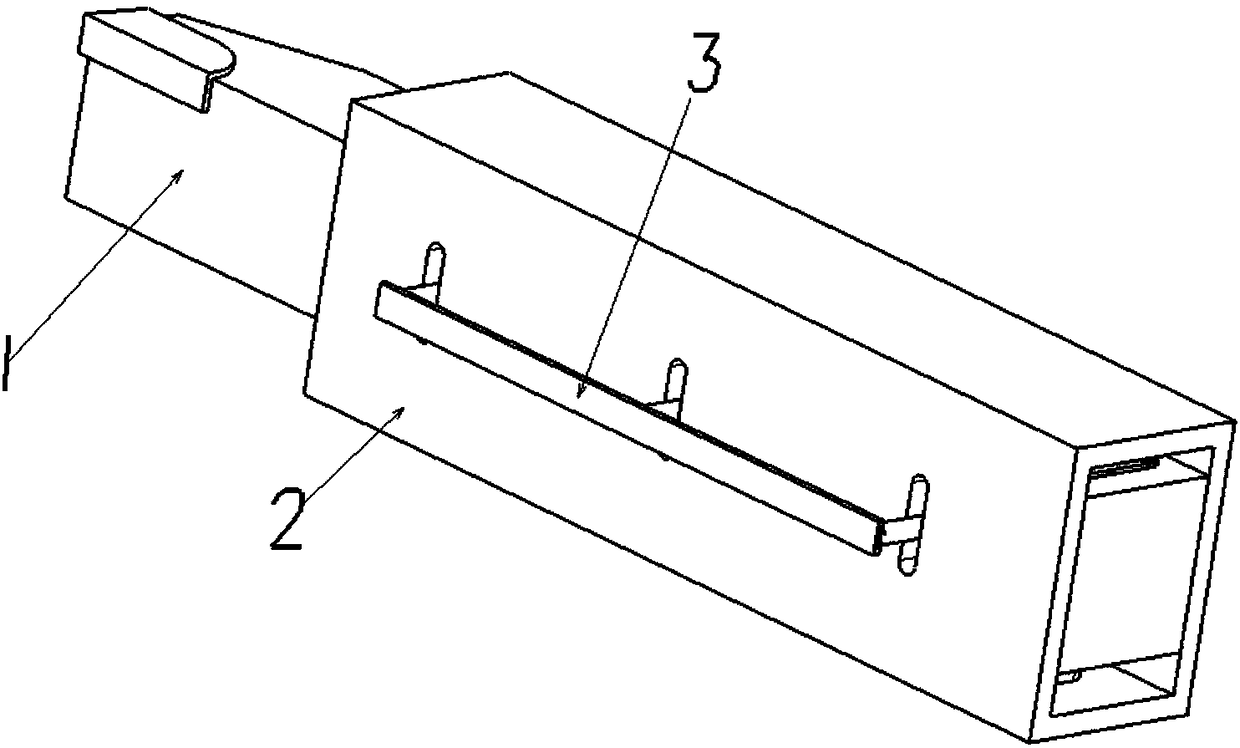

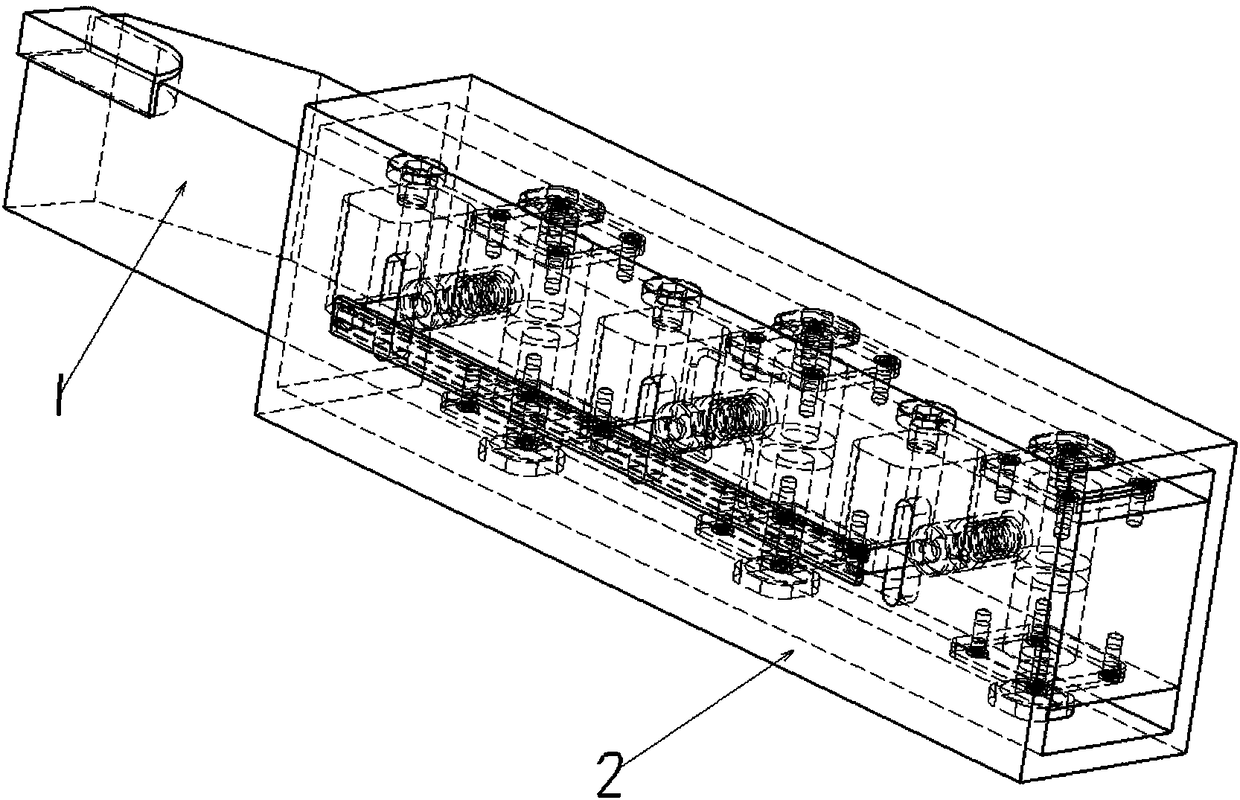

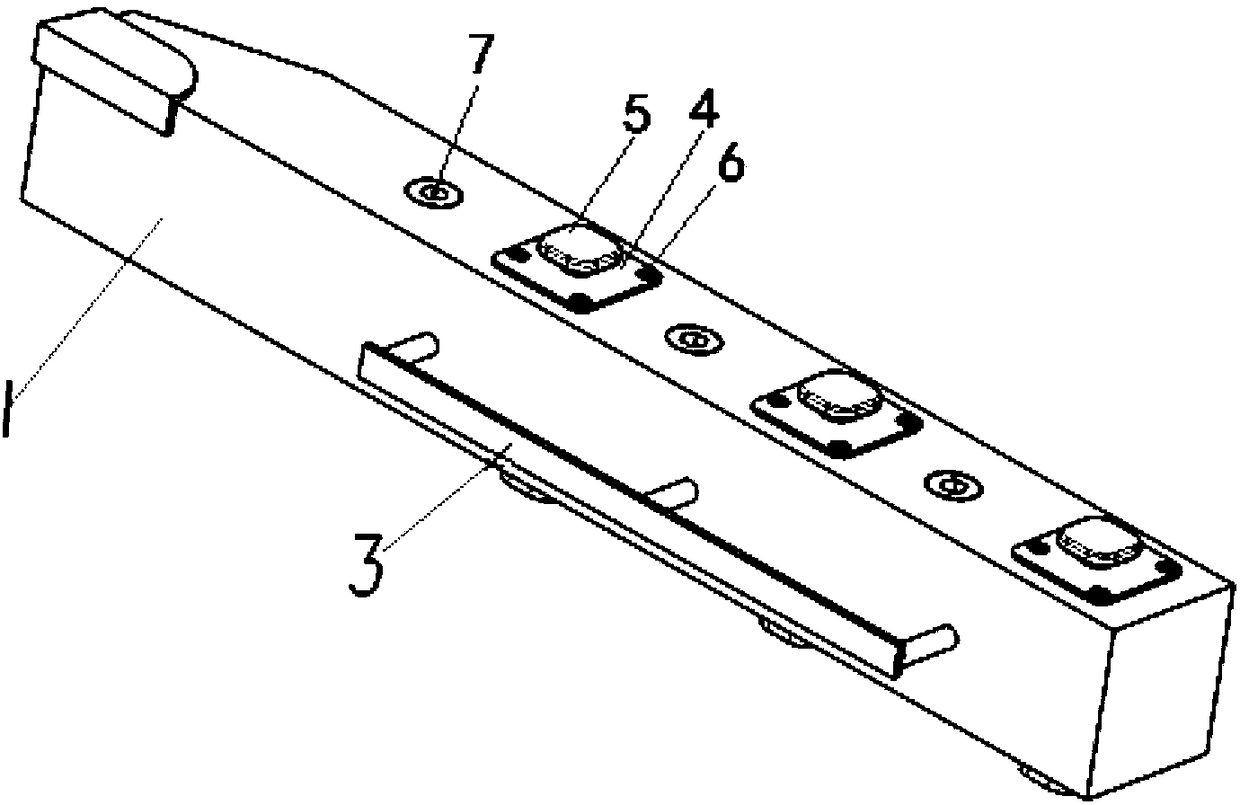

[0042] The hydraulic height-adjustable turning tool proposed by the present invention can use 3 sets of hydraulic height-adjusting mechanisms. When installed on a lathe, the installation position should ensure that the end of the piston 5 is aligned with the tightening screw on the tool holder, and then push the handle 3 , after the pull-out valve 8 is moved, the oil circuit is connected, and then the height of the cutter body 1 is adjusted to a suitable position, and the handle 3 is released, and the pull-out valve 8 returns to its position under the action of the spring 9, while pulling The piston of type valve 8 blocks the oil passage, and the piston 5 inside the cutter body 1 cannot move, and the height of the cutter body 1 is fixed and locked.

[0043] The hydraulically height-adjustable turning tool of the present invention has the following advantages: it can be conveniently used in lathe processing, and the installation height of the turning tool can be adjusted steples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com