Vehicle dually used for highways and railways

A technology for road-rail dual-purpose vehicles, which is applied to track and road dual-purpose vehicles, motor vehicles, transportation and packaging, etc. Long alignment time and other problems, to achieve the effect of fast up and down track

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

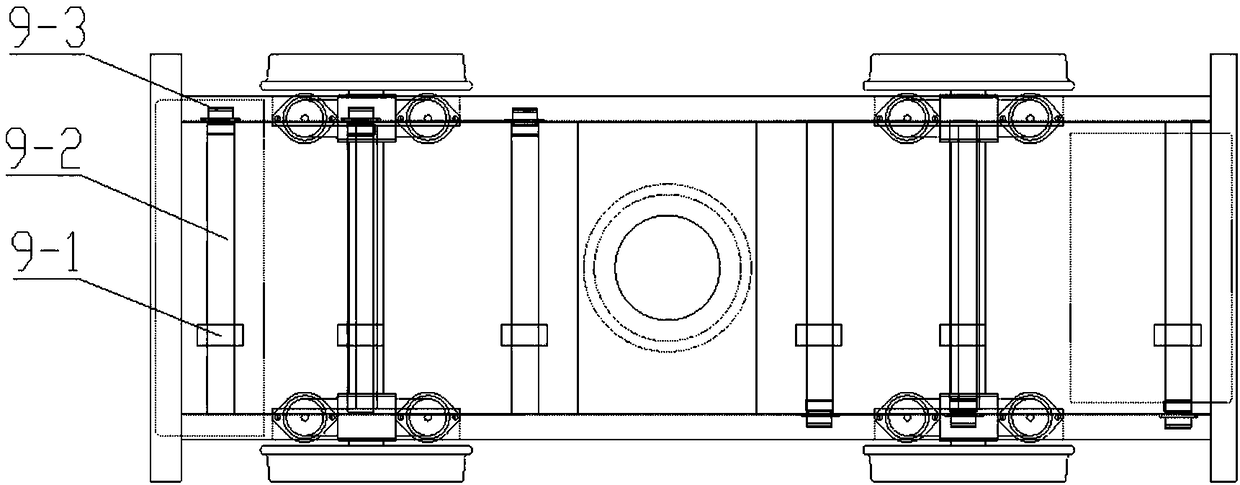

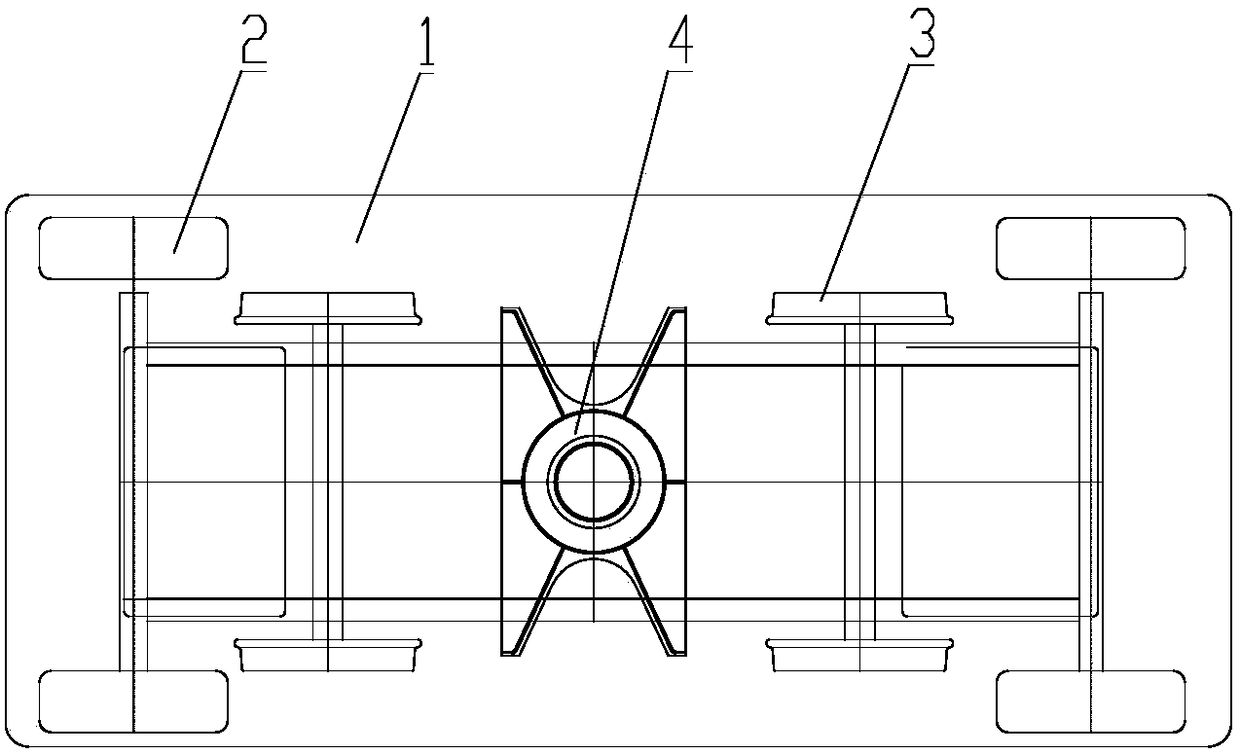

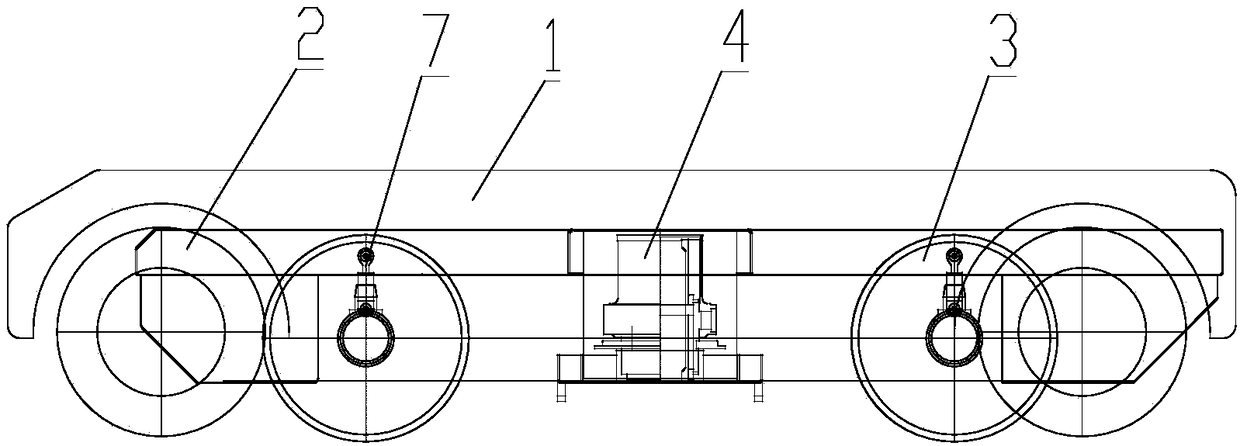

[0034] Figure 1 to Figure 3 A preferred embodiment of a road-rail vehicle according to the invention is shown. As shown in the figure, the road-rail vehicle includes a vehicle body 1 and a lifting and rotating mechanism 4 located at the bottom of the vehicle body 1 and connected to the vehicle body 1. The road-rail vehicle also includes a track wheel drive system 3 and a road wheel drive system 2 that are respectively connected to the vehicle body 1, wherein the track wheel drive system 3 is used for running on the track 6, and the road wheel drive system 2 is used for running on the track 6. Driving on roads, wet dirt roads, etc.

[0035]When in use, first the road-rail vehicle is driven perpendicular to the longitudinal direction of the track 6 onto the track 6 through the road wheel drive system 2, and then the lifting and rotating mechanism 4 is extended downwards and the road-rail vehicle is lifted to a certain extent. height, so that the lowest point of the road-rail ...

Embodiment 2

[0077] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

[0078] Such as Figure 13 As shown, in this embodiment, the track wheel drive system 3 is rotationally connected with the vehicle body 1 through the rotating mechanism 8, and the road wheel drive system 2 remains stationary relative to the vehicle body 1, so that the bottom of the road wheel drive system 2 is higher than Or lower than the bottom of the track wheel drive system 3, thereby realizing the switching between the road wheel drive system 2 and the track wheel drive system 3.

[0079] Specifically, the track wheel drive system 3 includes a front track wheel drive unit and a rear track wheel drive unit at the front end of the vehicle body 1, respectively, and the front track wheel drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com