A valve mechanism and engine capable of monitoring valve clearance on-line

A valve clearance and valve mechanism technology, which is applied in the directions of machines/engines, engine components, mechanical equipment, etc., can solve the problems of accurately monitoring the actual valve clearance, etc., and achieve the effects of accurate and reliable monitoring results and simple monitoring structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

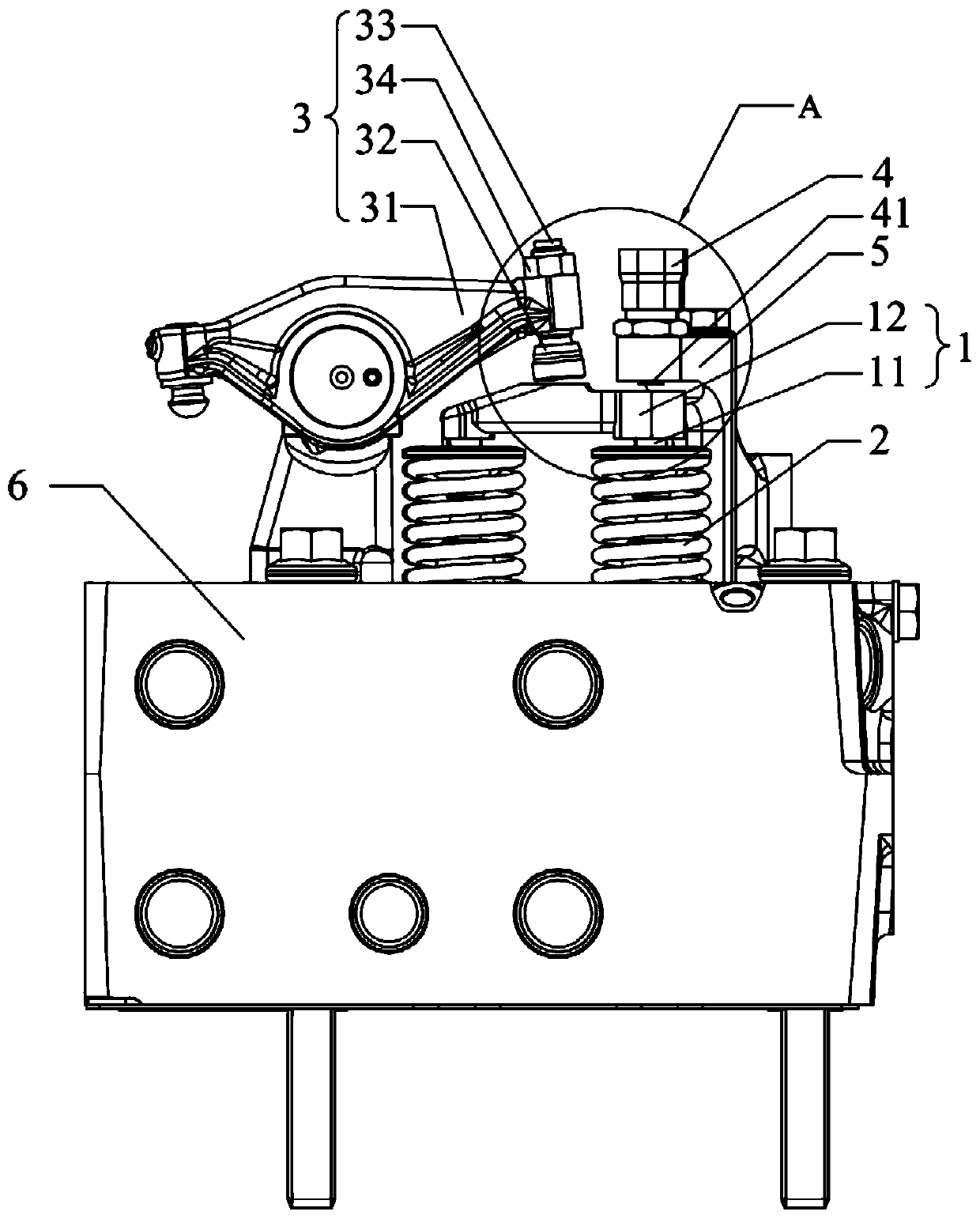

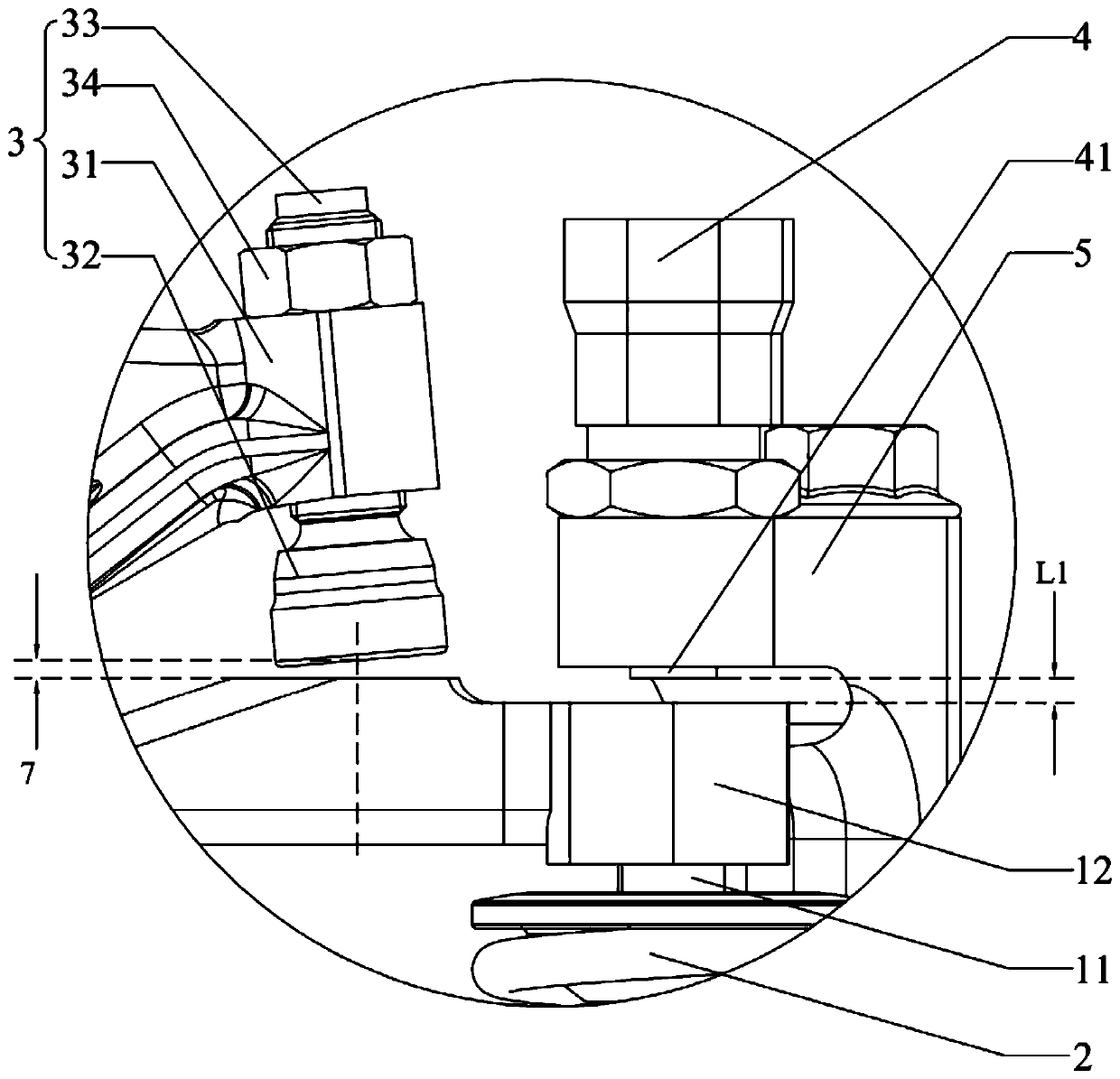

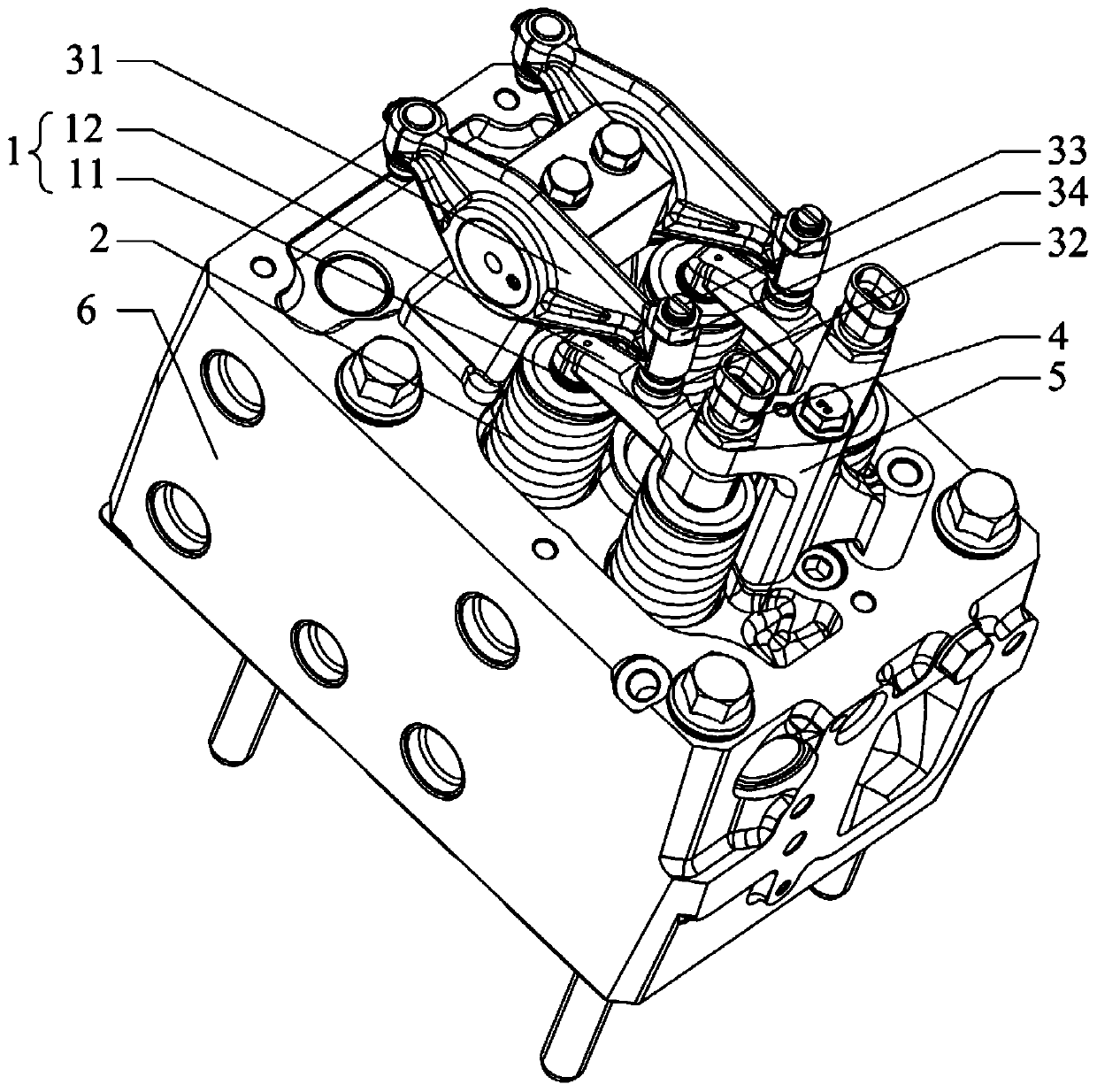

[0040] This embodiment provides a valve mechanism that can monitor valve clearance online, such as Figure 1~3 As shown, it includes: a valve assembly 1, a rocker arm assembly 3, a valve spring 2, a valve seat (not shown in the drawings), a valve wear sensor 4, and a sensor bracket 5. The valve assembly 1 is used for engine exhaust or intake, and it passes through the cylinder head 6 of the engine, the valve spring 2 passes through the valve assembly 1, and the top end of the valve spring 2 and the valve assembly 1 near the top of the boss When abutting, one end of the bottom abuts against the cylinder head 6 and the valve spring 2 is in a compressed state, which applies a force away from the cylinder head 6 to the top of the valve assembly 1 to facilitate the return of the valve assembly 1 after the rocker arm assembly 3 is pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com