Grinding pad finisher and grinding pad finishing method

A technology for grinding pads and dressers, which is applied to the parts of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problems of unsatisfactory dressing effect of grinding pads and complex structure of grinding pad dressers, etc., to achieve Improve the grinding effect, easy to implement, and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

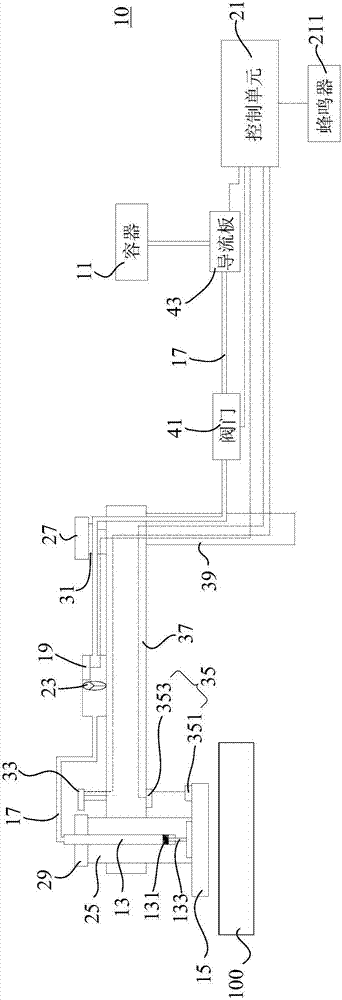

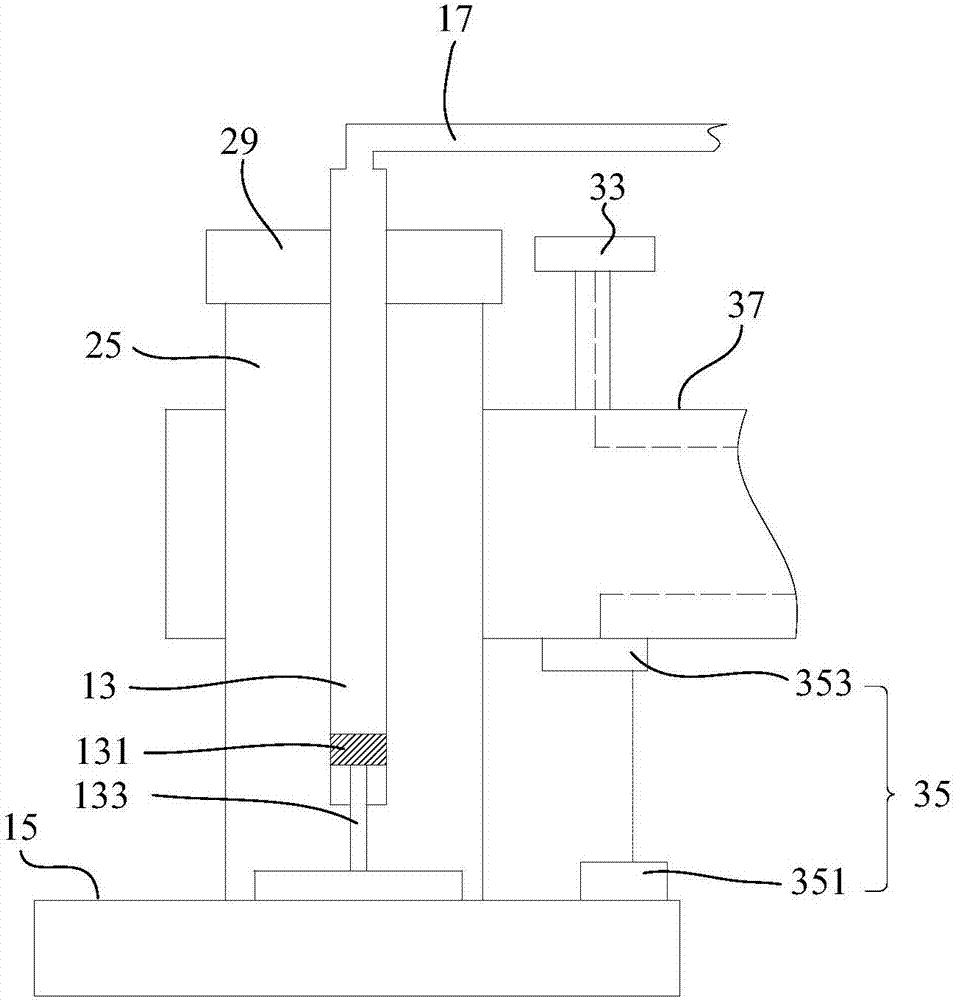

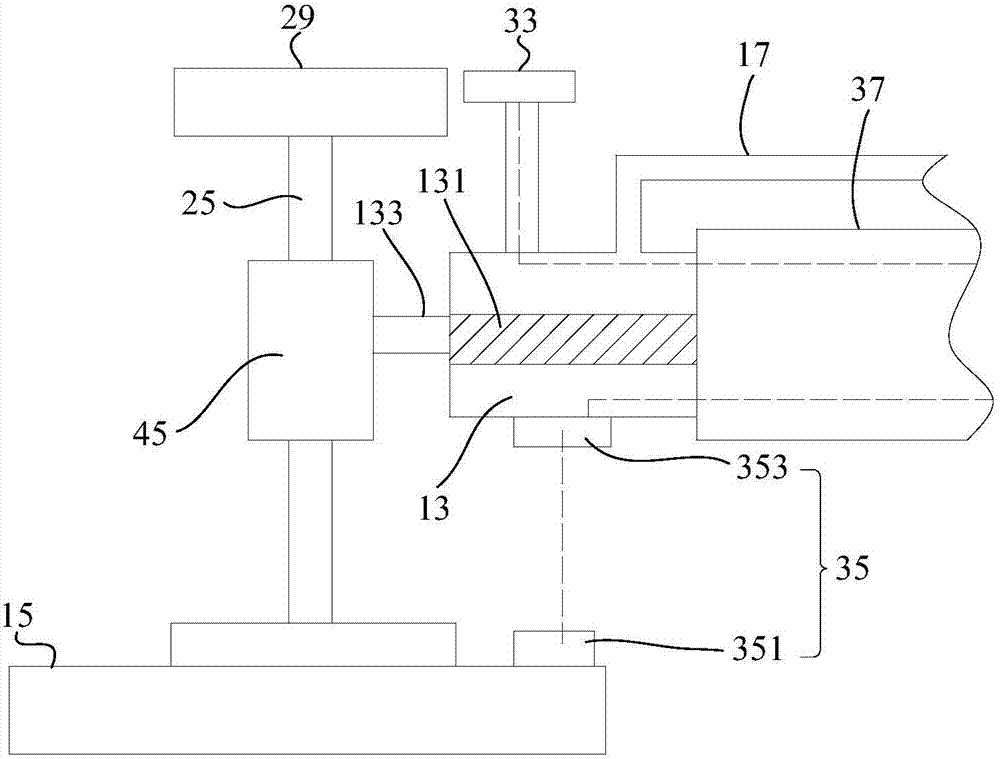

[0045] The inventors have studied the prior art and found that in most cases, the unstable dressing pressure of the dressing disc is the most important reason for the low material removal rate and poor flatness of the grinding pad. In order to solve the problem of unsatisfactory dressing effect of the polishing pad in the prior art, the present invention provides a polishing pad dresser and a polishing pad dressing method.

[0046] The invention provides a polishing pad dresser, which is used in the wafer manufacturing process to dress a polishing pad so that the surface of the polishing pad is flattened, which includes:

[0047] a dressing disc for dressing a grinding pad;

[0048] a fluid pressure driving unit, connected to the trimming disc, and used to drive the trimming disc to move through fluid power;

[0049] A control unit, connected to the fluid pressure driving unit, used to control the fluid pressure driving unit to drive the conditioning disc to press against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com