Cleaning structure for flat mop and cleaning tool thereof

A flat mop and cleaning structure technology, applied in the field of cleaning appliances, can solve the problems of increased material cost and transportation cost, increased volume of cleaning tools, unclean mop, etc., and achieves wide wiping range, durable structure, and convenient water injection operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

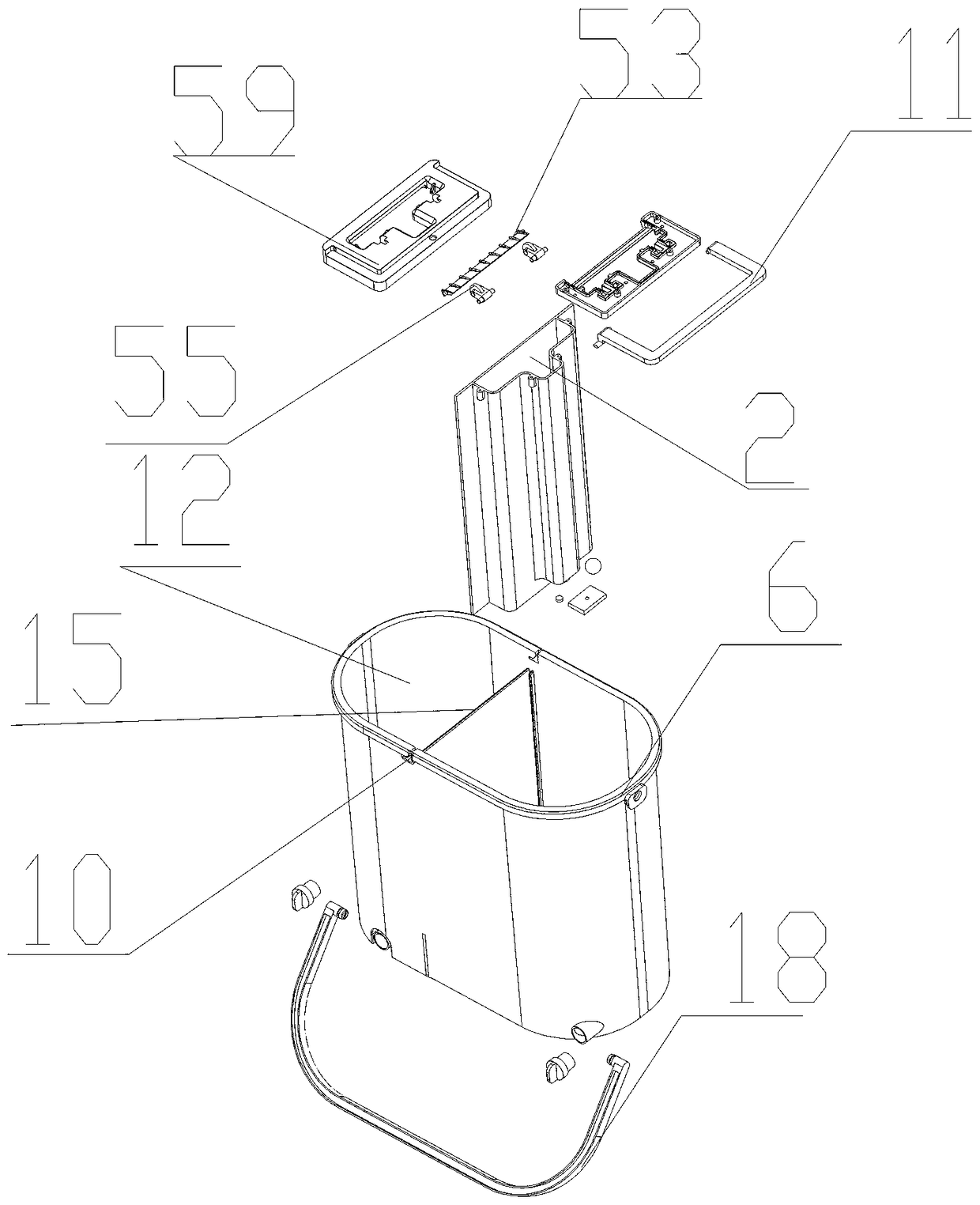

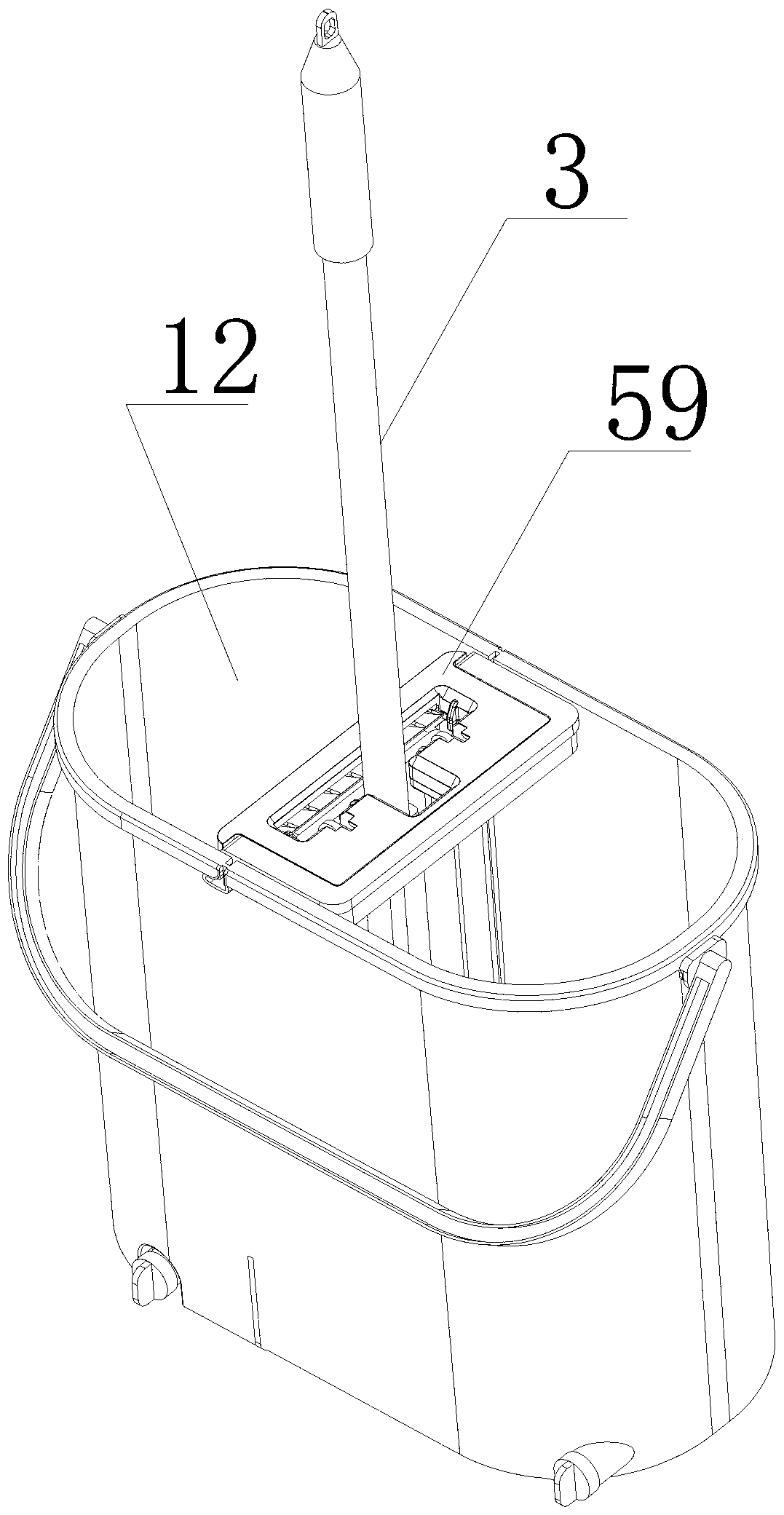

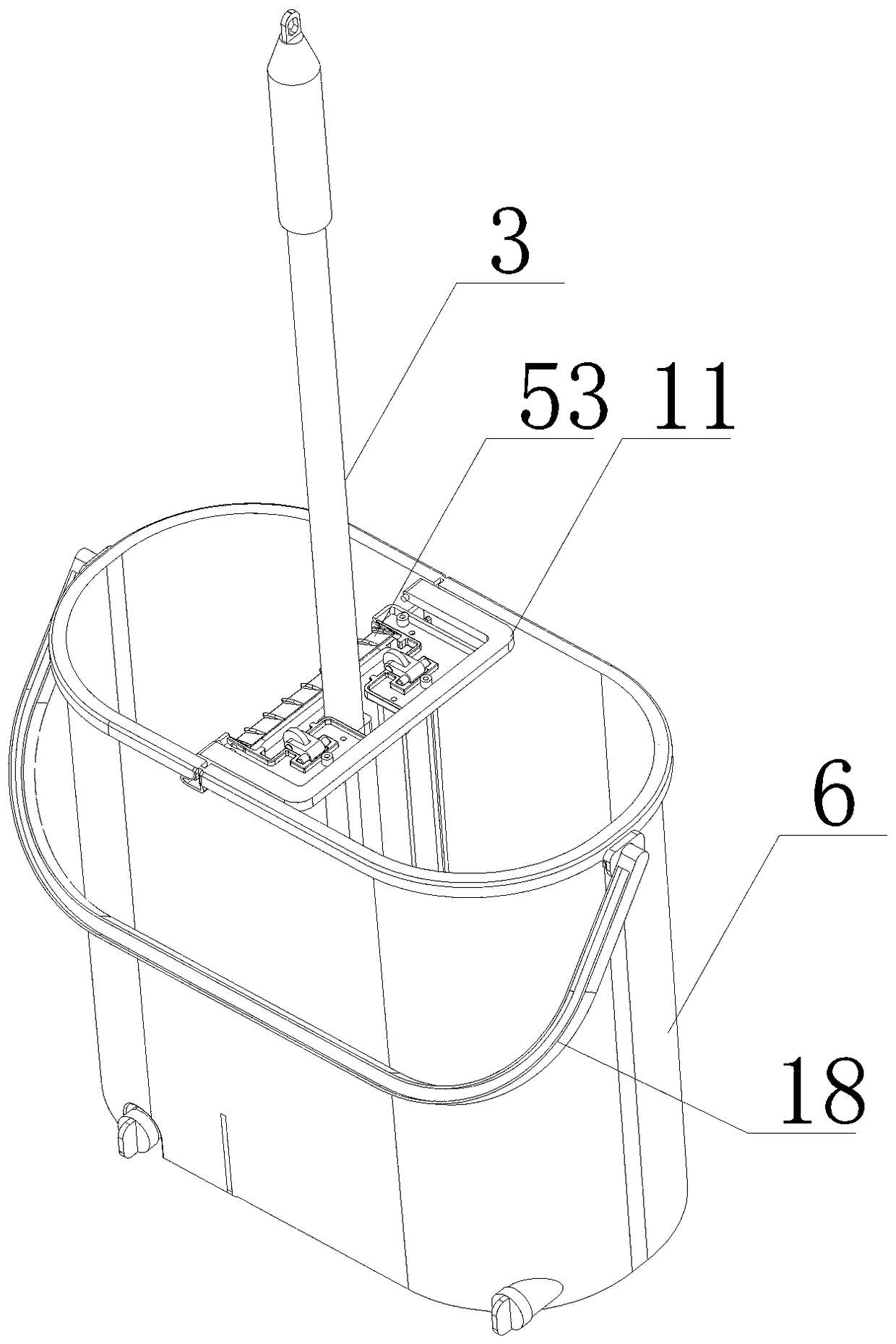

[0067] Such as Figure 1 to Figure 12 Shown, a kind of flat mop cleaning structure of the present invention comprises:

[0068] The working chamber includes a side wall 1 and an installation opening 2 surrounded by the side wall;

[0069] The scraping part 5 is detachably connected to the installation port 2, and the flat mop 3 extends into the working chamber through the scraping part for cleaning, and the scraping part 5 scrapes and presses the flat mop 3 to realize the decontamination of the flat mop 3 and dehydration;

[0070] There is also a housing 6 for containing cleaning water and passing the cleaning water into the working chamber;

[0071] The scraping part 5 is equipped with a sewage channel 4, and the sewage channel 4 cooperates with the scraping part 5 to discharge the sewage or dirt squeezed out by the cleaning mop;

[0072] The working chamber extends into the housing 6 and is detachably installed on the installation port 2. The working chamber is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com