Hanging tool for welding

A technology for hangers and workpieces to be welded, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor hanging stability of hangers, achieve good hanging and fixing effects, convenient and stable pick-and-place operations sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

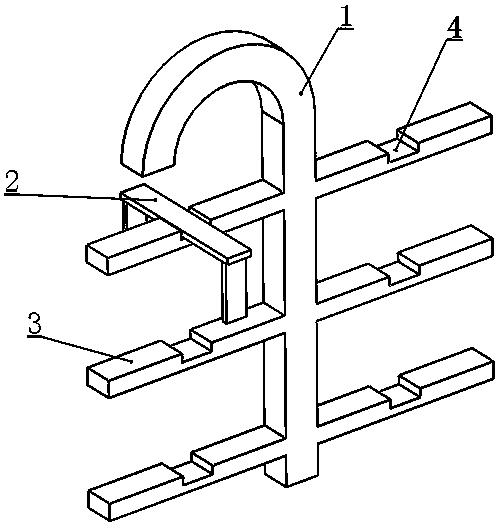

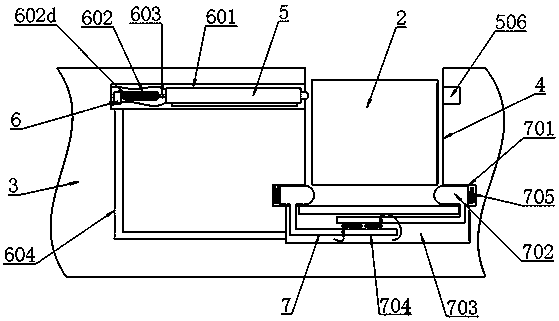

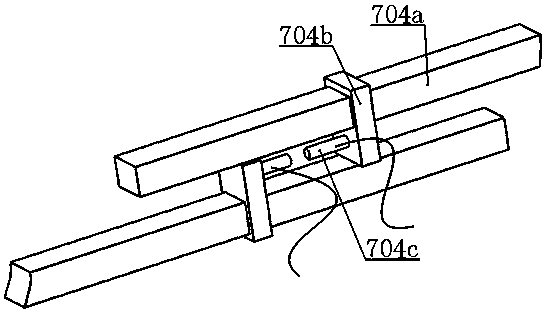

[0023] Example: as attached figure 1 , 2 , 3, 4 and attached Figure 5 As shown, a welding hanger includes a bracket 1, and a beam 3 arranged on the bracket 1 and used to place the workpiece 2 to be welded, and also includes a beam 3 arranged on the upper surface of the beam 3 and used to place the workpiece to be welded. The fixing groove 4 of the welding workpiece 2 is arranged on the fixing groove 4 and is used to cover and compress the pressing unit 5 of the workpiece 2 to be welded. It is arranged in the beam 3 and is used for driving by magnetic repulsion. The electromagnetic unit 6 of the pressing unit 5 , and the trigger unit 7 arranged in the beam 3 and used to communicate with the electromagnetic unit 6 by pushing downwards.

[0024] In the existing hanger, the workpiece to be welded is only hung on the hanger. At this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com