Manufacturing method of light composite load-bearing wall

A production method and technology for load-bearing walls, which are applied in the direction of walls, building components, buildings, etc., can solve the problems of poor wall integrity, failure and damage of self-tapping screws, heat preservation, sound insulation, fire resistance, impact resistance and poor hanging ability, etc. Achieve the effect of high fire resistance, good sound insulation and low steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

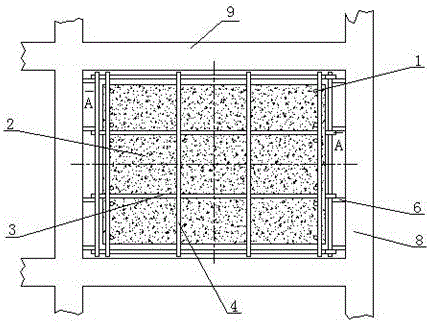

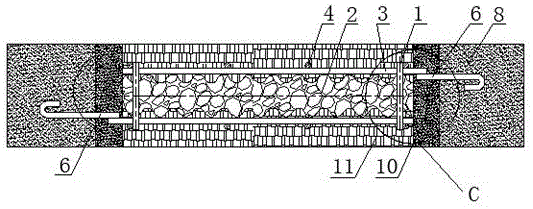

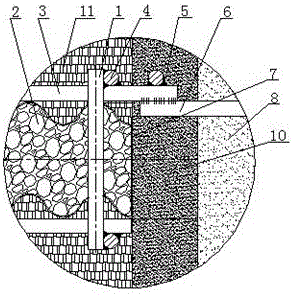

[0042] Such as Figure 1-Figure 6 As shown, a method for making a lightweight composite load-bearing wall, including an edge reinforcement component composed of a connecting beam 9 and a vertical restraint member 8, is characterized in that:

[0043]In the two opposite vertical constraining members 8, a plurality of connecting steel bars 6 with outcrops are pre-embedded alternately, and on the same horizontal plane, the outcrop on one vertical constraining member 8 is close to the inner side of the vertical constraining member 8, and the opposite The outcropping of the pre-embedded reinforcement on another vertical restraint member 8 is close to the outside of the vertical restraint member 8;

[0044] Along the middle of the thickness direction between the two vertical constraining members 8, the built-in foam insulation board 2 is formed by spraying straw fly ash fine stone concrete 11, and then spraying ordinary fine stone concrete 10 near the edge reinforcement parts to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com