Two-wheel differential motion robot chassis

A robot and chassis technology, applied in the field of robot research and development, can solve the problems such as the inability to install the structural suspension mechanism and the small remaining space of the chassis, and achieve the effects of optimal suspension, less chassis space occupation, and scientific and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

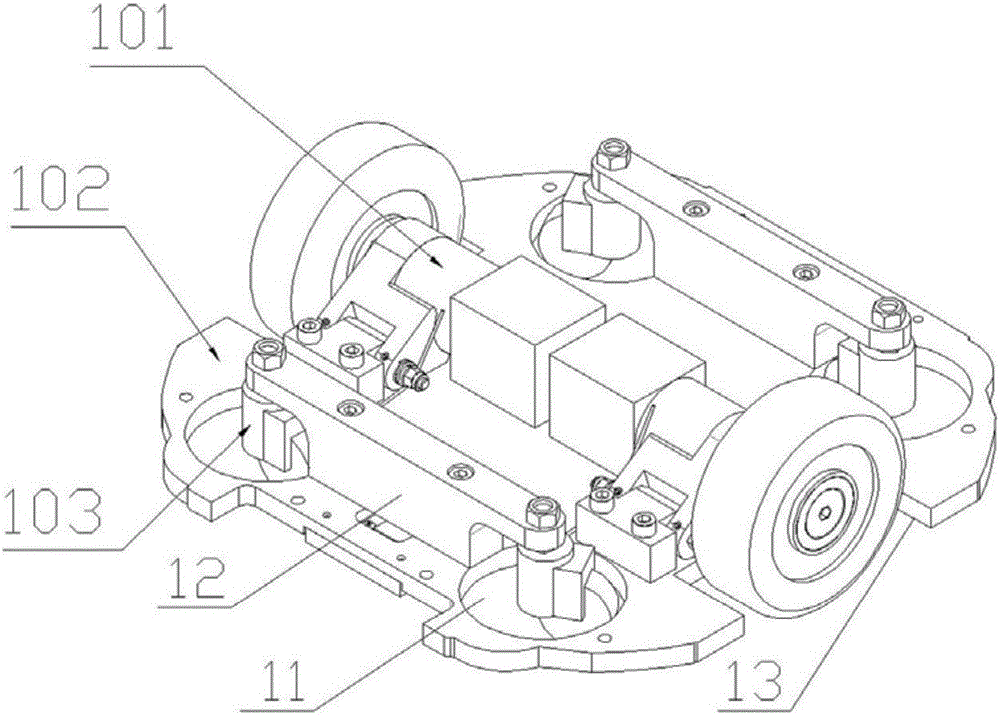

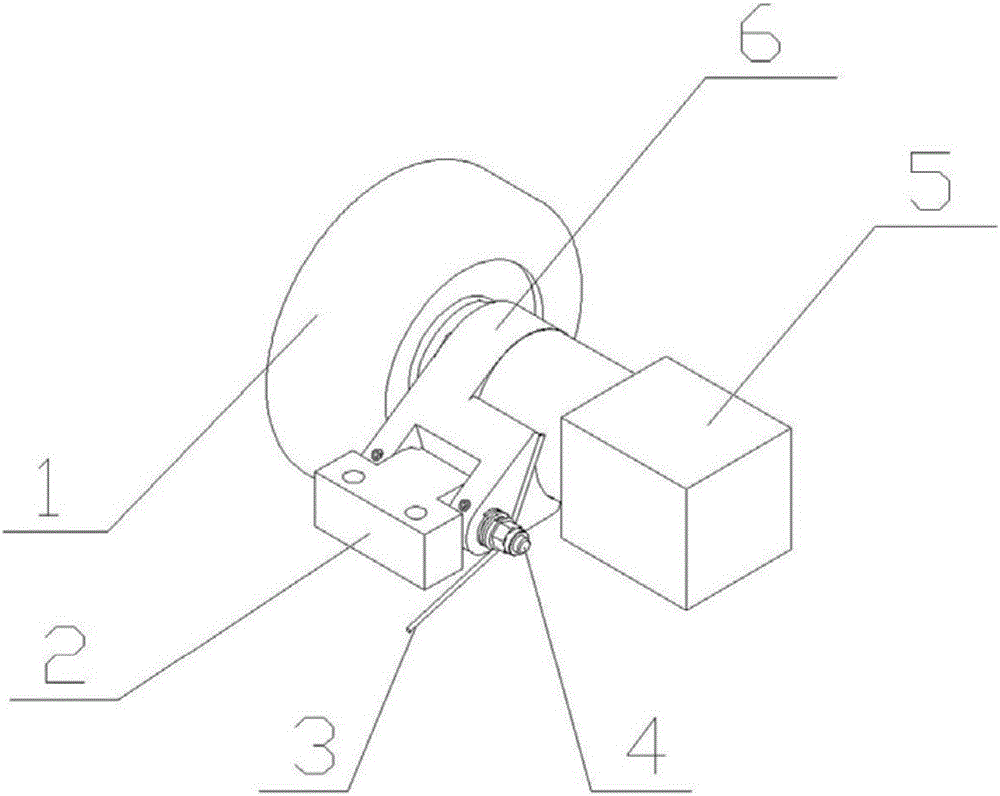

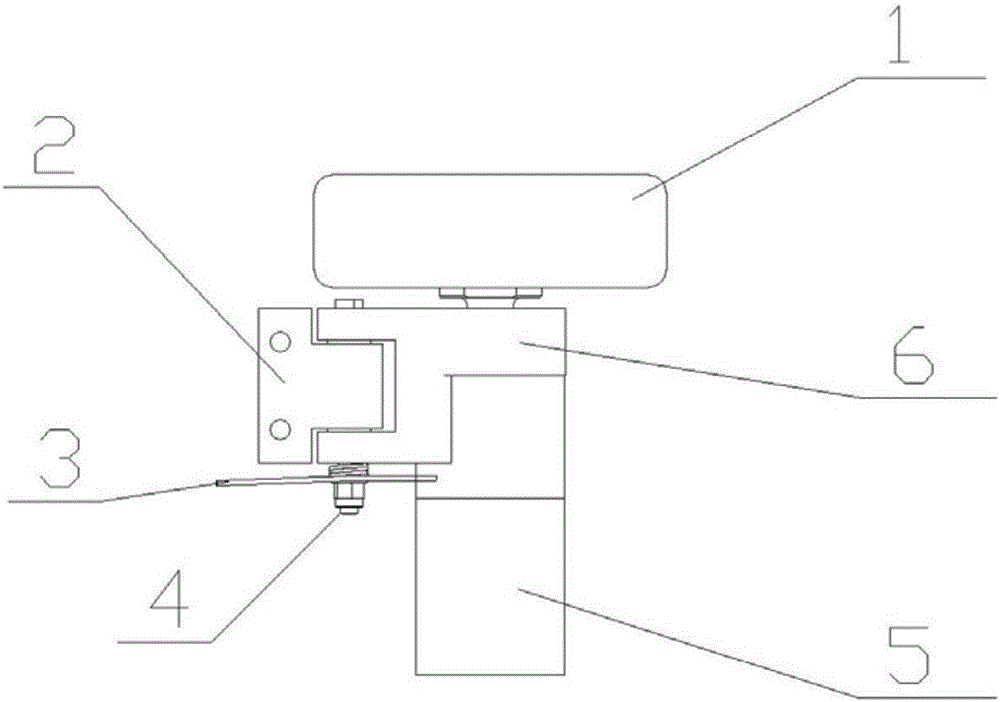

[0035] see figure 1 , with reference to Figure 2-Figure 9 , shown in the figure is a two-wheel differential robot chassis involved in the present invention, and the key technical solutions adopted are as follows:

[0036] As shown in the figure, the chassis involved in the present invention mainly includes a bottom plate 102, on which a pair of suspension mechanisms 101 are fixedly connected with the bottom plate 102 through connecting pieces.

[0037] Suspension mechanism 101 comprises a suspension bracket 6, the driving wheel 1 that is movably connected with this suspension bracket 6, and the drive motor 5 that adopts direct connection mode to be connected with driving wheel 1; The suspension bracket 6 is provided with a rotating shaft parallel to the output shaft of the motor 4. The rotating shaft 4 is pierced with a suspension mount 2 fixedly connected to the bottom plate 102; the extended end of the rotating shaft 4 is provided with a torsion spring 3, and one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com