Cleaning equipment for bottom of vehicle

A technology for cleaning equipment and vehicles, applied in the field of vehicle cleaning, to achieve the effect of simplifying procedures, offsetting damage, and good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

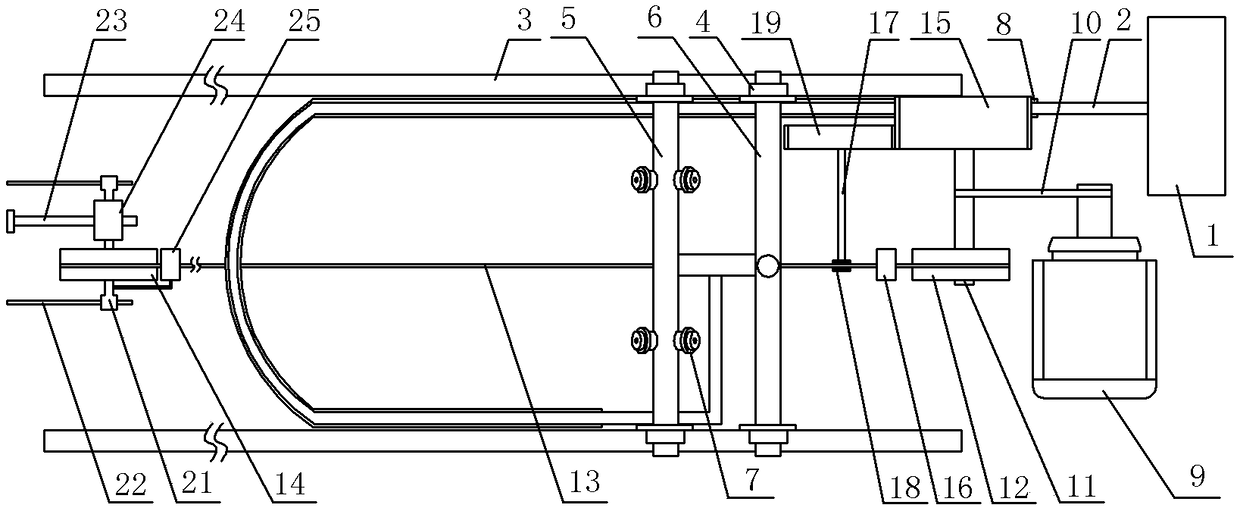

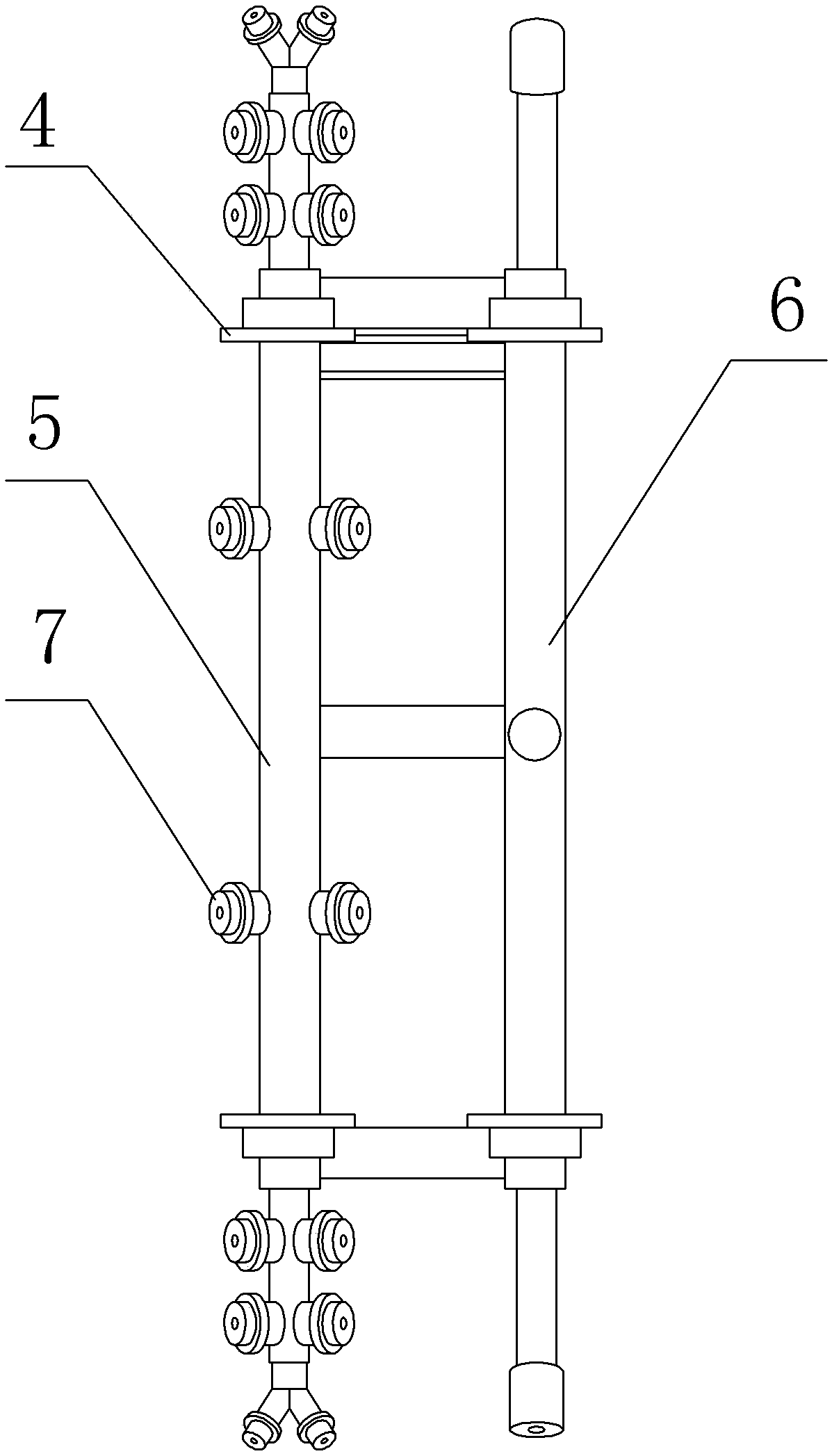

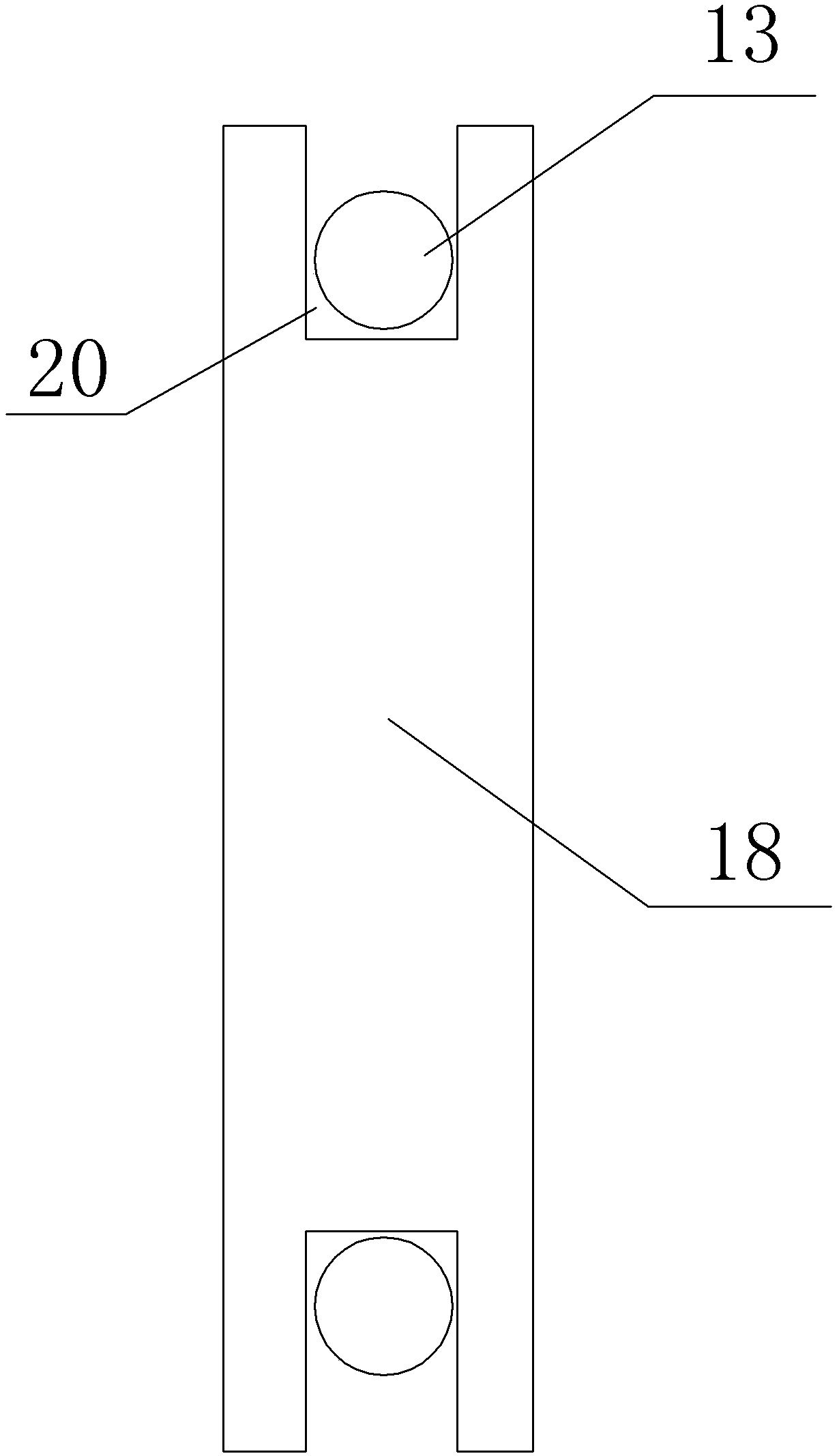

[0020] The reference signs in the drawings of the description include: decontamination tank 1, decontamination pipe 2, track 3, spray vehicle 4, cleaning pipe 5, disinfection pipe 6, nozzle 7, one-way drag chain 8, waterproof DC motor 9, chain 10. Rotating shaft 11, driving wheel 12, wire rope 13, driven wheel 14, first gear 15, guide wheel 16, detection rod 17, detection block 18, second gear 19, bayonet 20, support shaft 21, optical axis 22 , screw rod 23, nut 24, guide block 25, arc groove 26.

[0021] Such as figure 1 The shown cleaning equipment for the bottom of the vehicle includes a decontamination tank 1, a decontamination pipe 2, a driving mechanism, a detection mechanism, a track 3, a spraying vehicle 4 and a tensioning mechanism. The guide rail is composed of four guide rail components, and the guide rail components are spliced by bolts, which can greatly improve the convenience o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com