Intelligent integrated packaging system

An all-in-one, workbench technology, applied in the field of intelligent integrated packaging system, can solve the problems of uncontrollable manual operation, unguaranteed work efficiency, affecting the shipping progress of enterprises, etc., to ensure product packaging quality and save handling time. , the effect of good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

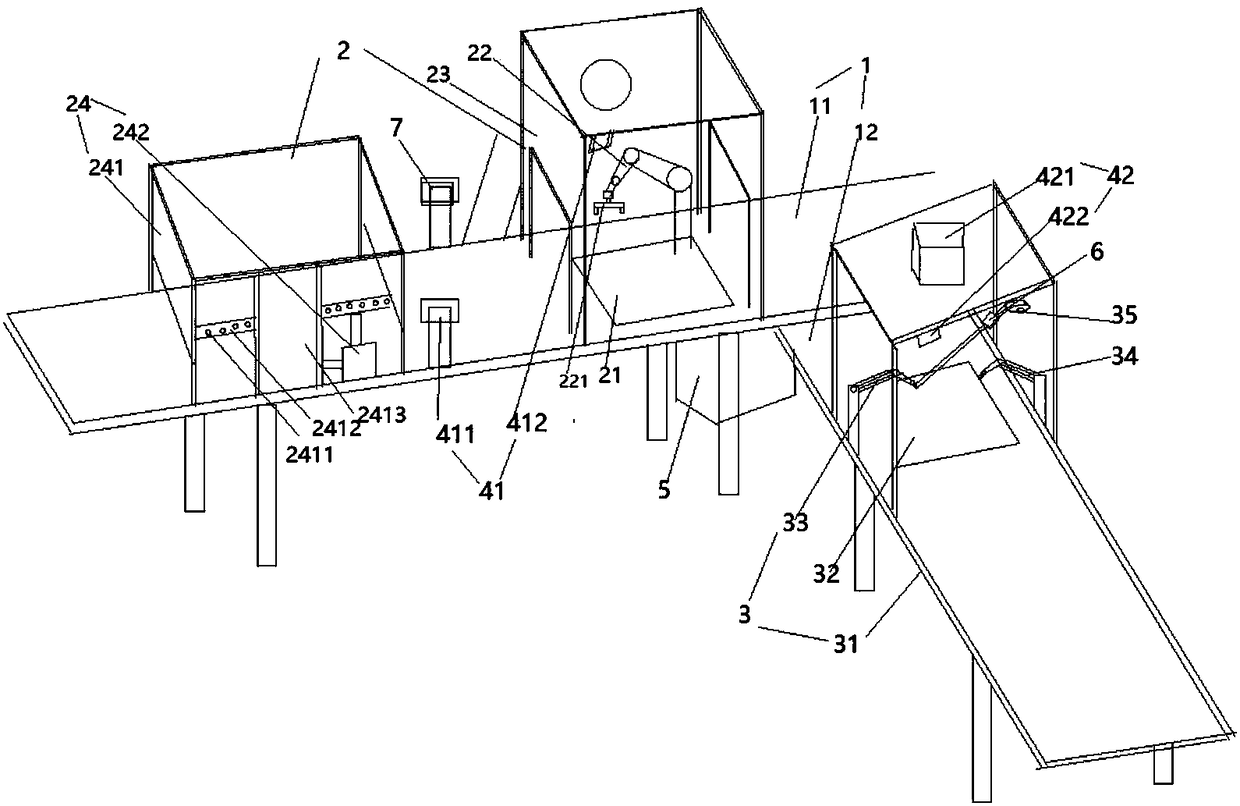

[0051] An intelligent integrated packaging system described in this embodiment includes: a conveyor belt 1, a packaging device 2, a sealing mechanism 3, a detection mechanism 4 and a control device 5, wherein the conveyor belt 1 is provided with a supply Conveyor belt 11 and packaging conveyor belt 12, the packing device 2 is arranged at the end of the delivery conveyor belt 11, the sealing mechanism 3 is arranged on the packaging conveyor belt 12, and the delivery conveyor belt 11 is arranged on the packaging One side of the conveyor belt 12, the detection mechanism 4 is provided with a packaging detection mechanism 41 for product appearance and position in the packaging process and a sealing detection mechanism 42 for detecting the sealing position, the conveyor belt 1, the packaging device 2. Both the sealing mechanism 3 and the detection mechanism 4 are connected with the control device 5 .

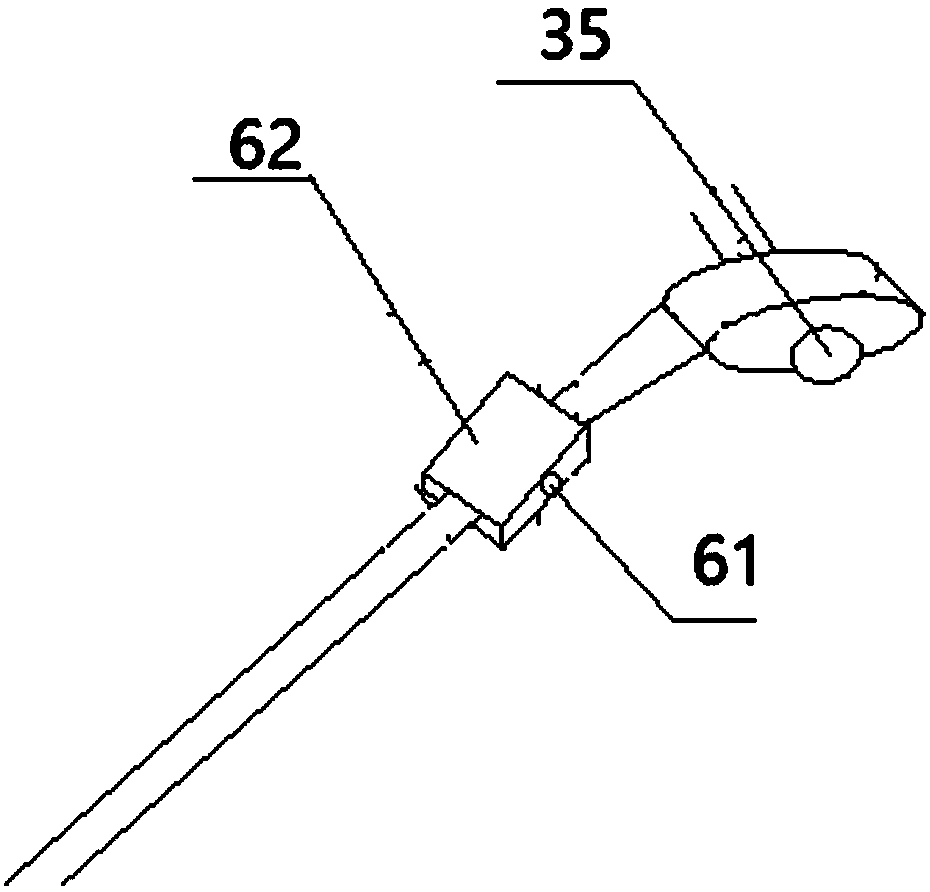

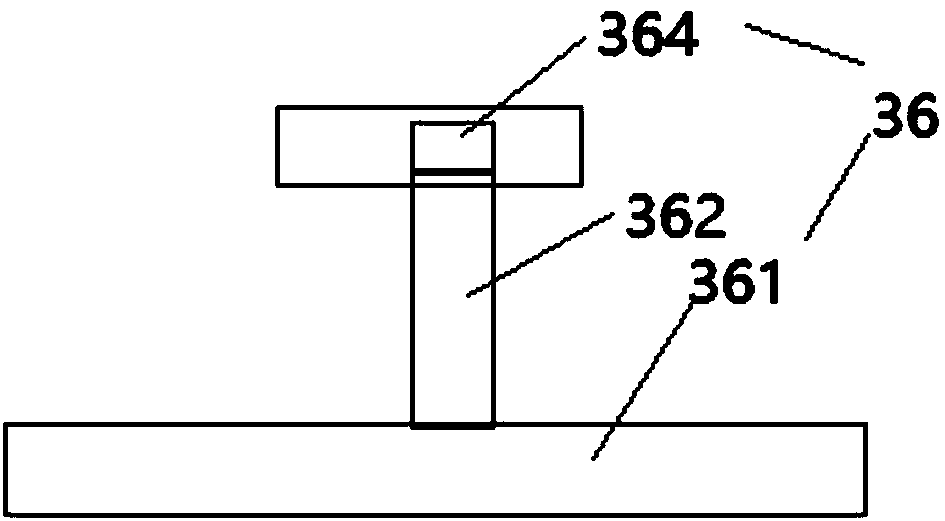

[0052] In the present embodiment, the packaging device 2 is provided with a packa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com