Unloading device and loading equipment

A technology of unloading device and loading equipment, applied in the field of loading and unloading, can solve the problems of reducing unloading efficiency, difficult to unload goods, difficult to push goods, etc., and achieve the effects of reducing manual unloading, increasing working area, and improving unloading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0120]The present invention provides an unloading device. In one embodiment, the unloading device can be installed on an existing loader, such as on a bucket of an existing loader, so that the existing loader constitutes a loading device and can be installed on the existing loader. The loader is driven to unload; in another embodiment, the unloading device can also directly replace the bucket of the existing loader so as to form a new type of loading equipment with the body of the loader for unloading.

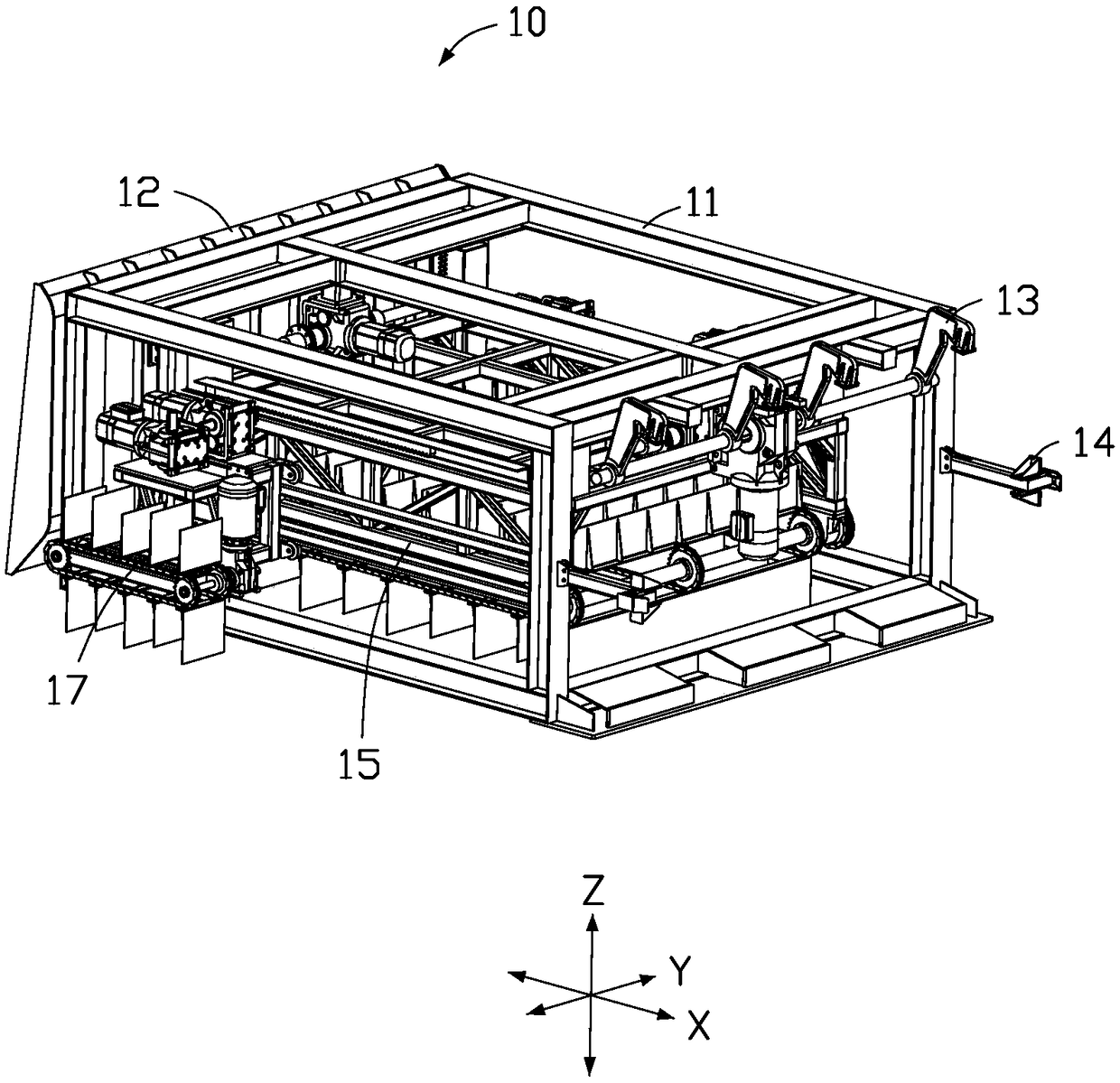

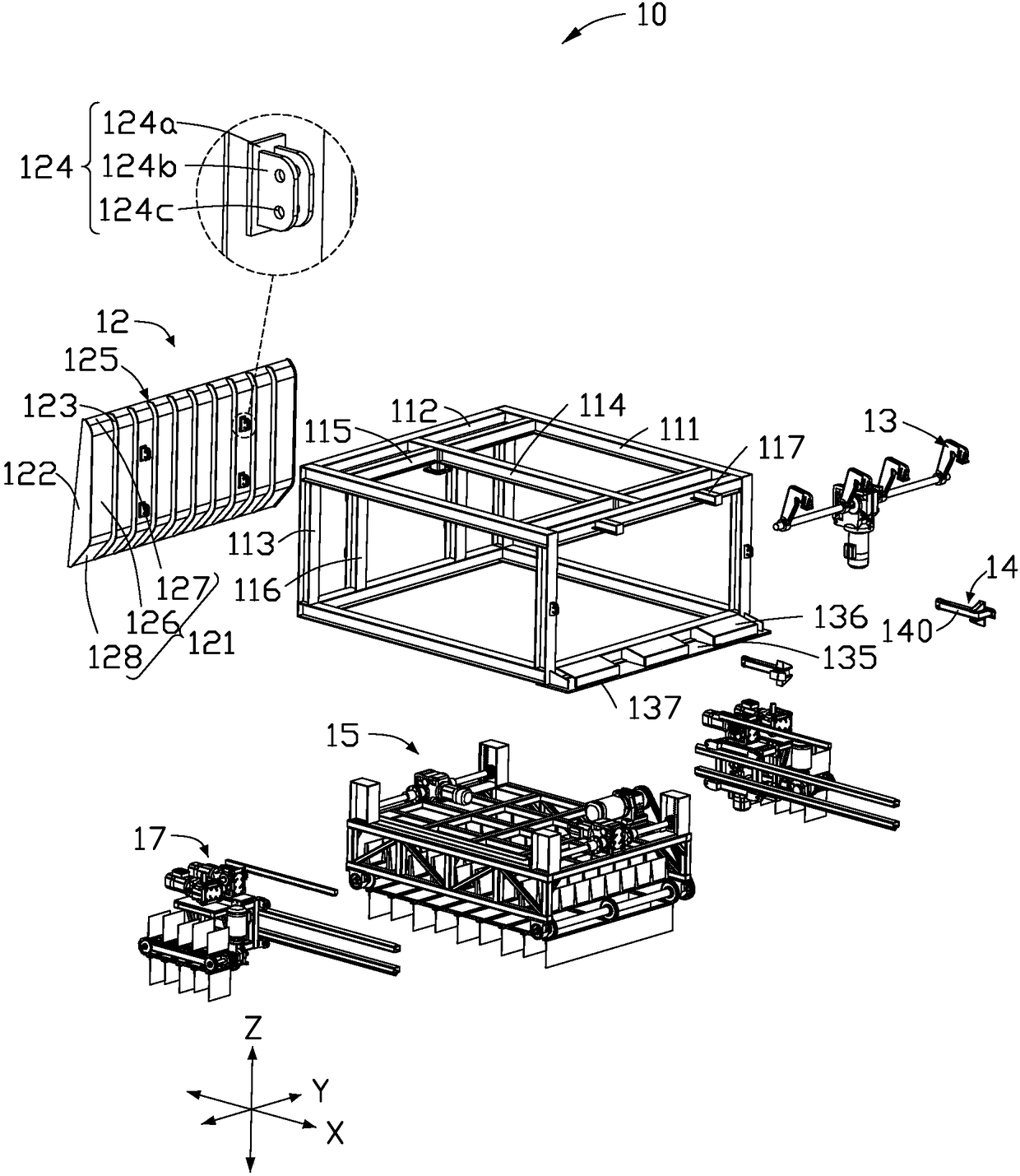

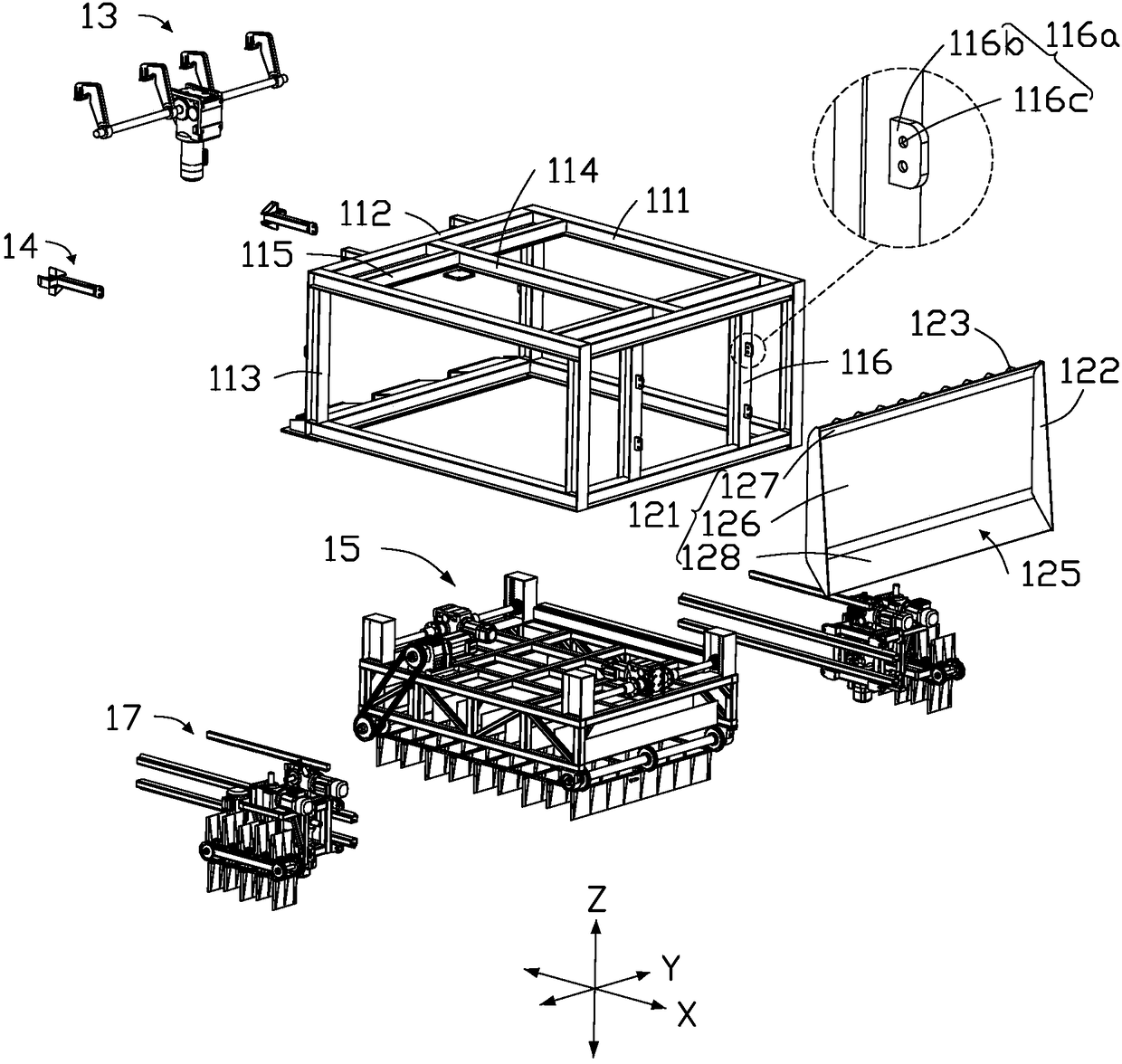

[0121] Such as figure 1 , 2 In the embodiment shown in , 3, the unloading device 10 installed on the bucket of the existing loader is mainly introduced. The guiding mechanism 14 , the first pushing mechanism 15 , and the second pushing mechanism 17 .

[0122] The support member 11 can be a bracket structure but is not limited to the above. The pushing member 12, the first pushing mechanism 15, the second pushing mechanism 17, the locking mechanism 13, and the installation g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com