A shock-absorbing and easy-unloading construction engineering trolley

A construction engineering and trolley technology, applied in trolleys, trolley accessories, single-axis trolleys, etc., can solve problems such as difficult and stable placement of trolleys, inability to adapt to different users, and inability to change the length of the handle, to avoid falling building materials, Save manpower and reduce the effect of manual unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

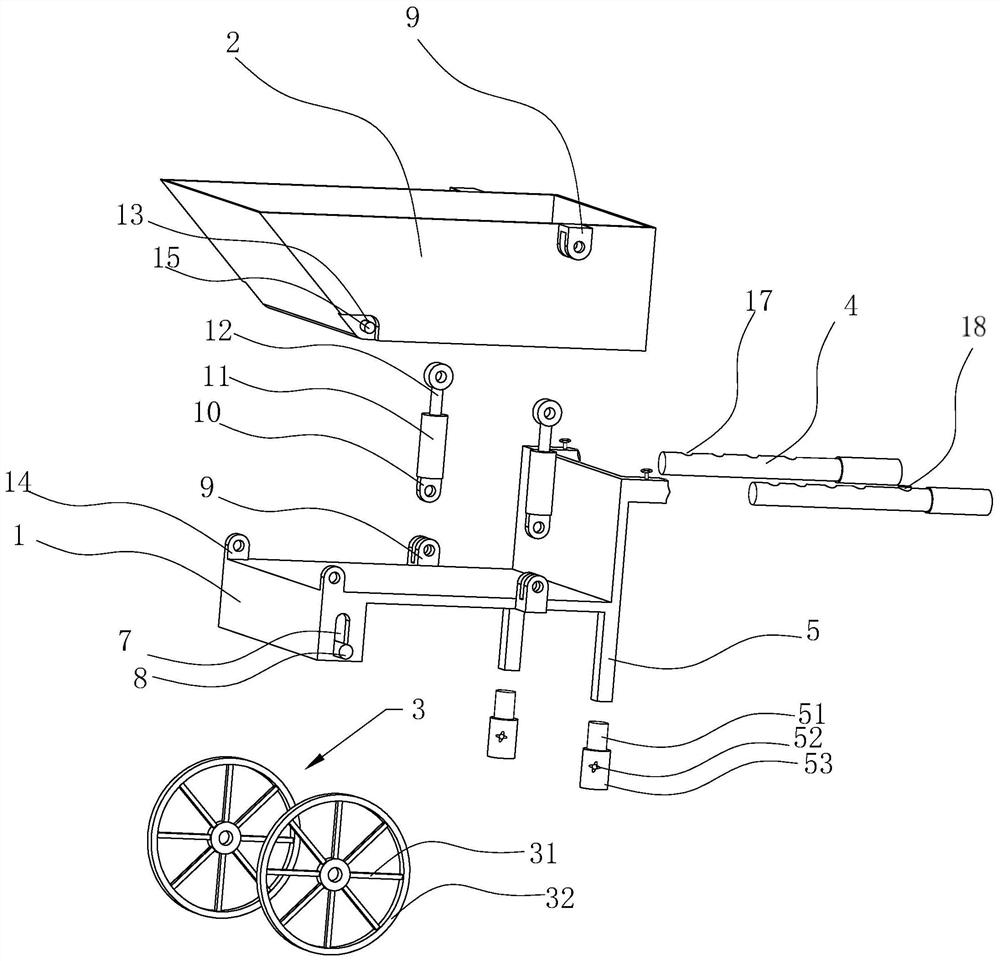

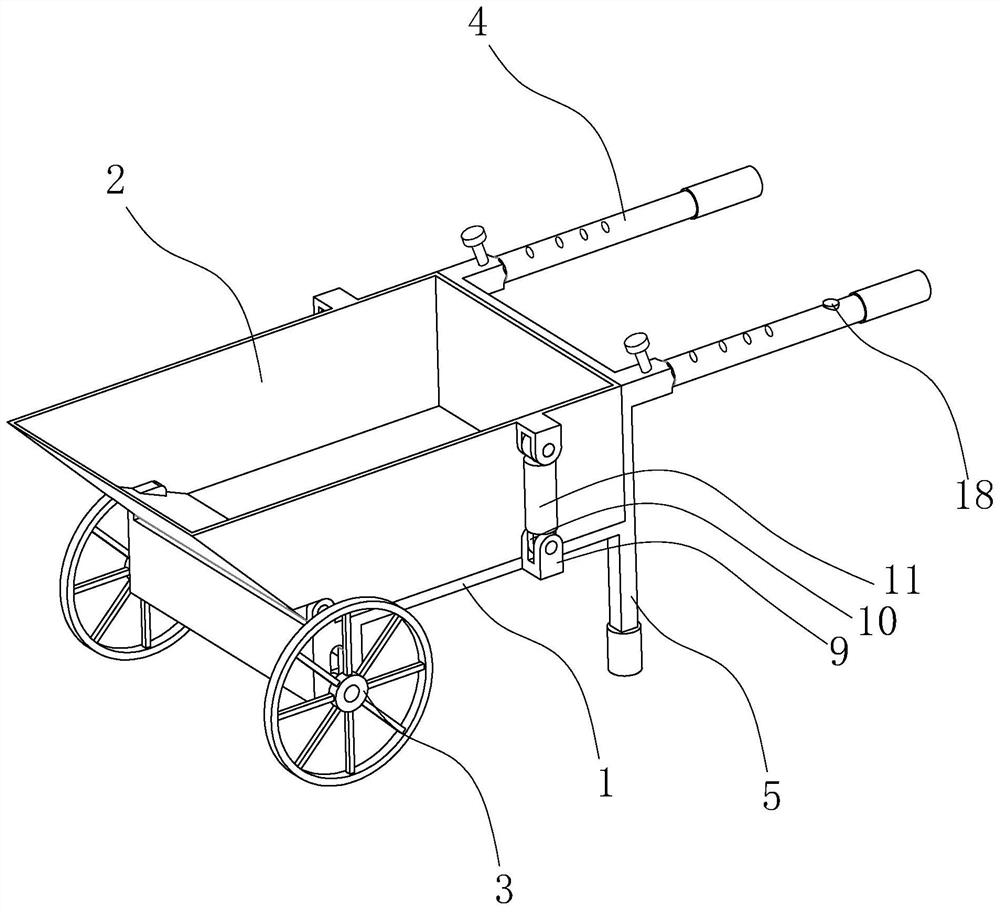

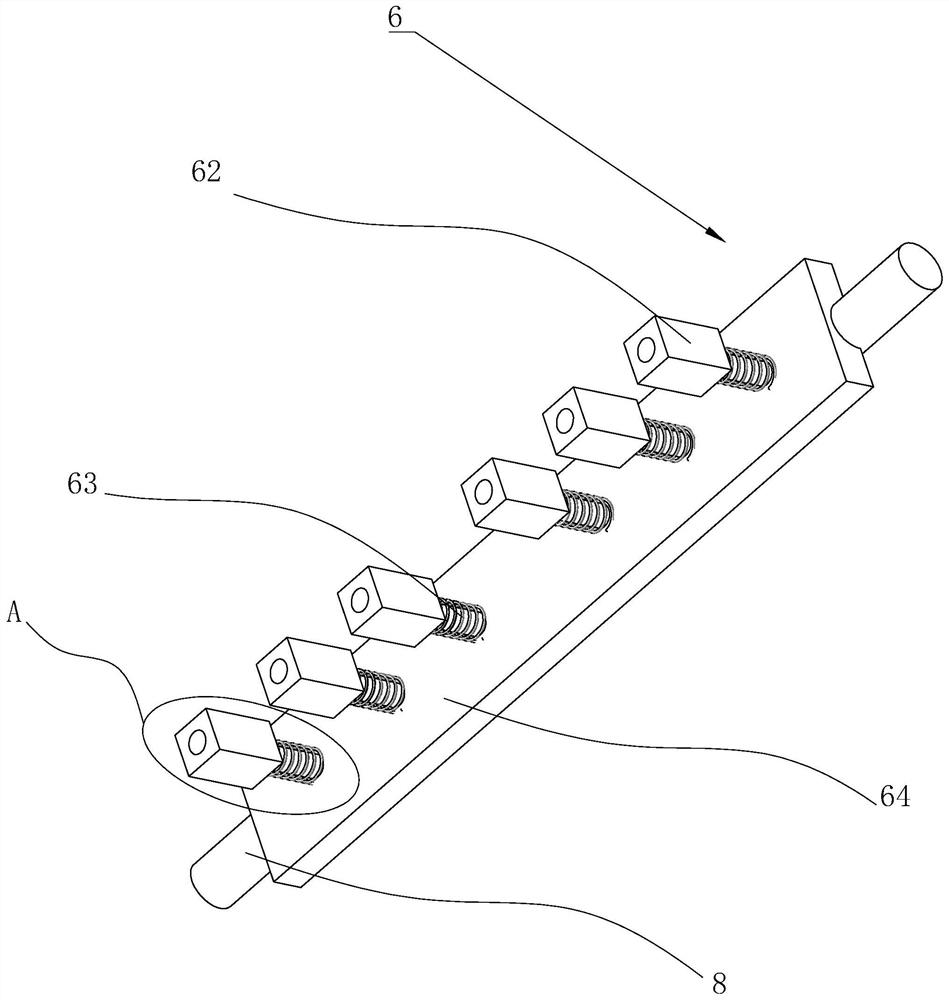

[0037] A kind of shock-absorbing and easy-to-unload construction engineering trolley, refer to figure 1 A vehicle body 2 is installed on the vehicle frame 1, wheels 3 are installed on both sides of the vehicle frame 1, and support legs 5 are welded below the vehicle frame 1. In this embodiment, the vehicle body 2 is an inverted trapezoidal structure.

[0038] refer to figure 1 , Both sides on the vehicle frame 1 are equipped with connecting lugs 9, and connecting keys 10 are installed below the cylinder 11. The connecting keys 10 are connected with the connecting ears 9, and are fixed together by bolts.

[0039] refer to figure 2 , cylinder 11 is provided with telescopic rod 12, and the top of telescopic rod 12 is welded with connection key 10, and this connection key 10 cooperates with the connection lug 9 that is welded on car body 2 both sides to be connected together, is fixed with bolt here equally.

[0040] refer to figure 2 , the lower end of the supporting leg 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com