Steel structure connector

A technology for connecting parts and steel structures, applied in building structures, buildings, etc., can solve the problems of steel structure collapse, easy deformation of section steel, affecting the overall assembly, etc., and achieve the effects of preventing prolapse, avoiding shearing, and improving friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

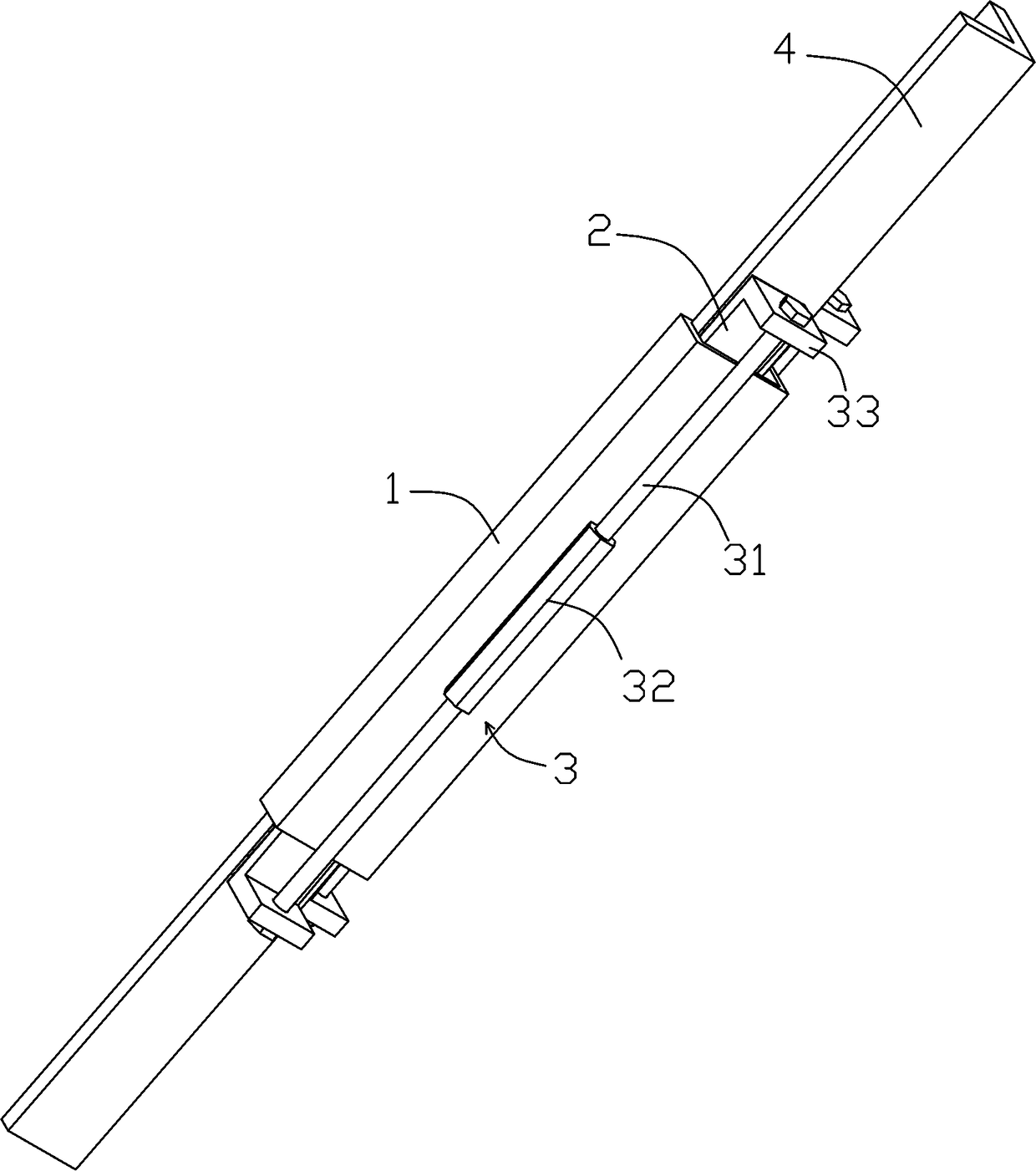

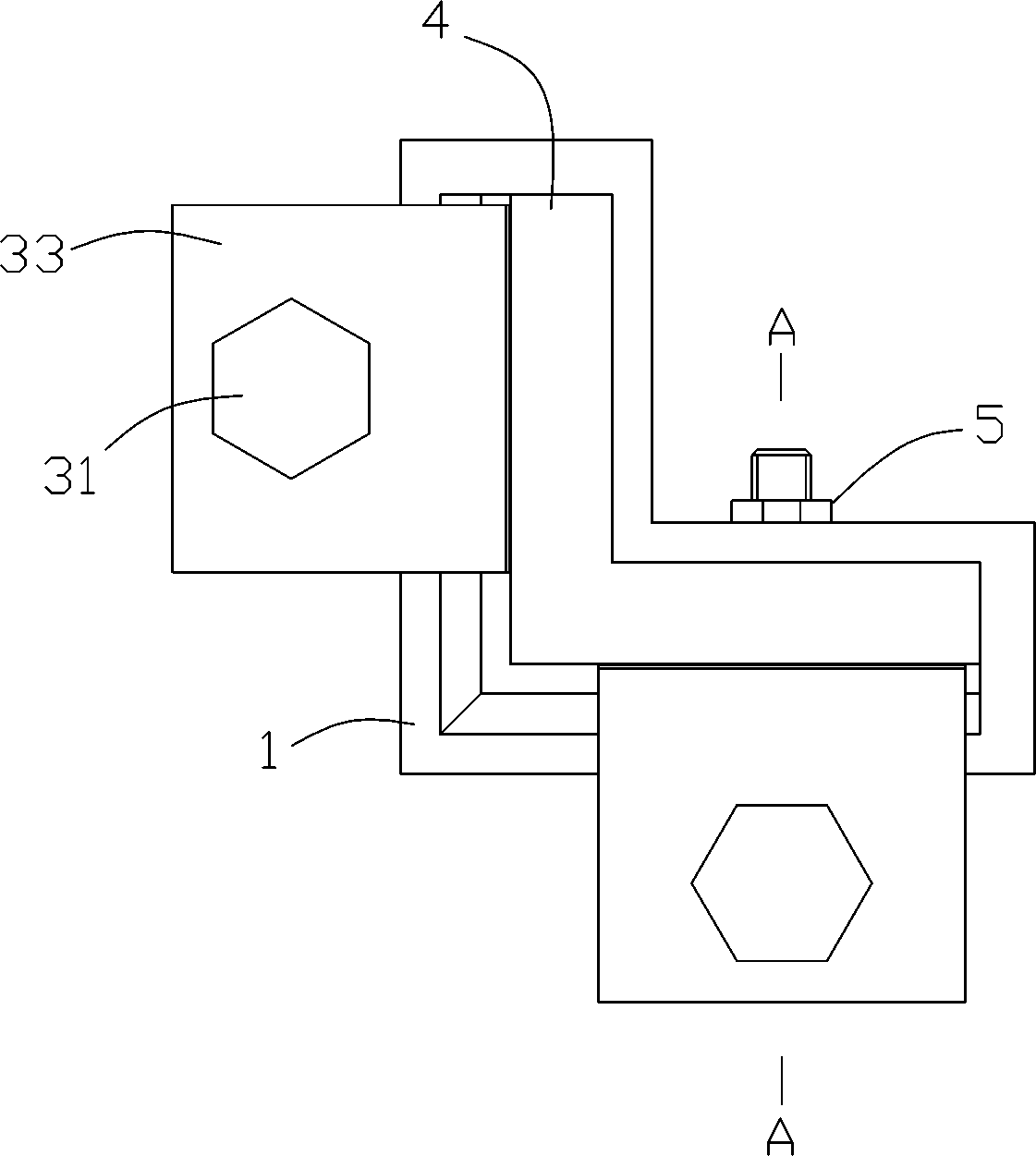

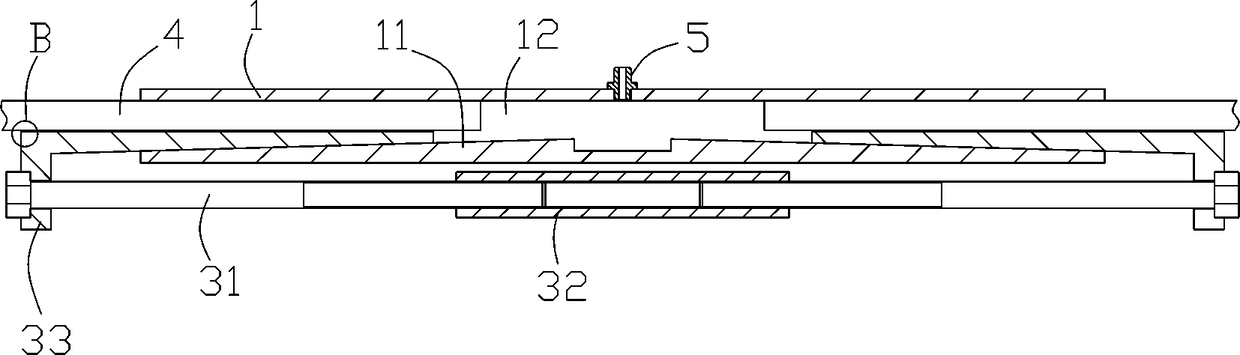

[0016] like Figures 1 to 4 Shown: a steel structure connector, including a pipe sleeve 1, a plurality of trapezoidal protrusions 11 are symmetrically arranged on both ends of the inner wall of the pipe sleeve 1, and the slope of the trapezoidal protrusions 11 and the inner wall surface of the pipe sleeve 1 form a wide outside and narrow inside. Trapezoidal channel 12, in each trapezoidal channel 12, insert a block 2 that one side is inclined-plane respectively, the inclined-plane of inserting block 2 sticks on the inclined-surface of trapezoidal protrusion 11, on the plane of inserting block 2 facing away from the inclined-plane, be provided with a plurality of convex Rib 21, a tightening device 3 for pulling the two inserts 2 into the sleeve 1 is installed on the two symmetrical inserts 2 at both ends of the sleeve 1.

[0017] The tightening device 3 includes protrusions 33 respectively fixed on one end of the two plug-in blocks 2, a screw rod 31 is installed on each protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com