Mine car wheel

A mining truck and wheel technology, which is applied in the direction of wheels, wheels and vehicle parts characterized by rail running parts, can solve problems such as affecting work and damage to rail mining trucks, and achieve the effect of reducing the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

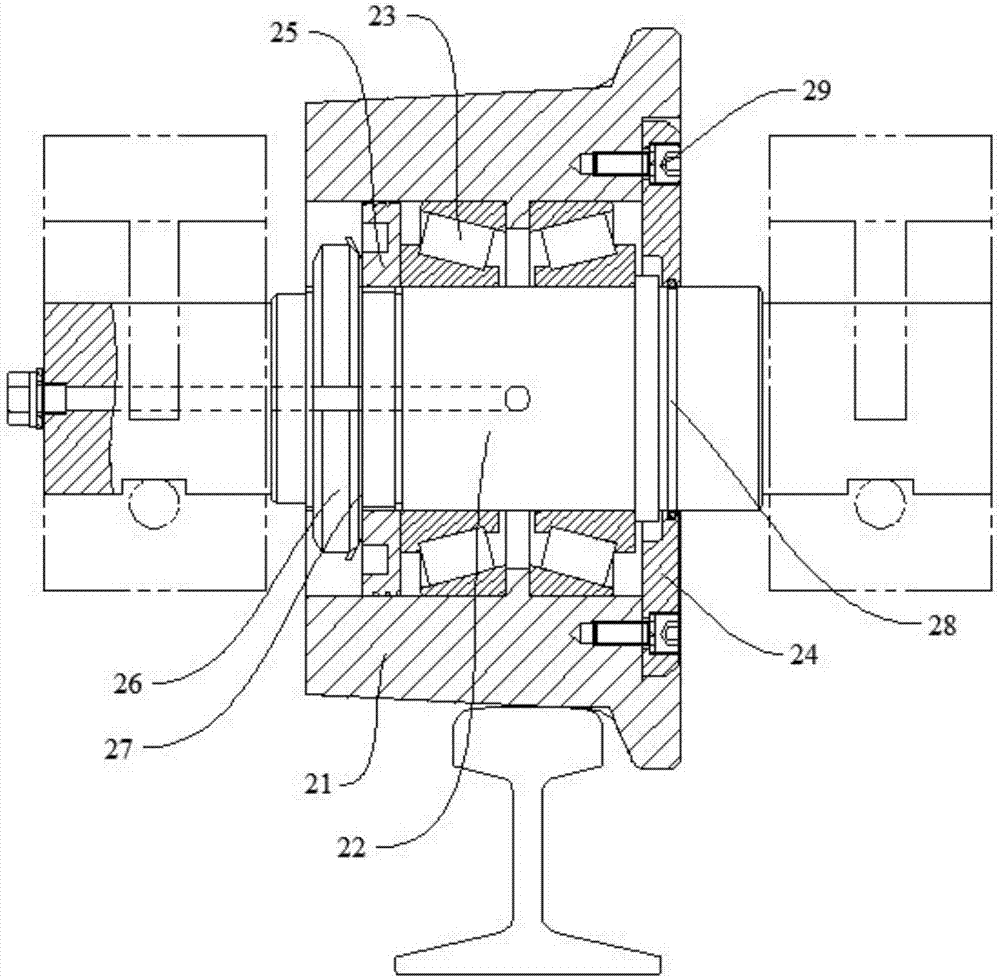

[0013] as attached image 3 Shown, a kind of mine vehicle wheel, comprises: wheel 21, axle shaft 22, bearing 23, inside sealing cover 24, outside sealing cover 25, round nut 26, stop washer 27, O type ring 28, bolt 29; The middle part of the shaft 22 is covered with a bearing 23, the outer side of the bearing 23 is fixed in the inner cavity of the wheel 21, and the end surface of the inner side of the wheel 21 is provided with an annular groove, and the inner sealing cover 24 is fixed in the annular groove by a bolt 29, and the thickness of the inner sealing cover 24 is less than or equal to the annular groove. The groove is deep, the half shaft 22 passes through the middle of the inner sealing cover 24, and the half shaft 22 and the inner sealing cover 24 are in sealing contact with the O-ring 28, the diameter of the outer sealing cover 25 matches the inner cavity of the wheel 21, and the outer sealing cover 25 is arranged in the inner cavity of the wheel 21, the outer sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com