A kind of U-shaped pipe chipless forming machine and its working method

An all-in-one machine and U-shaped tube technology, which is applied in the field of U-shaped tube chip-free forming all-in-one machines, can solve the problems of increased production process and production cost, easy extrusion deformation at the bend, and low degree of automation, and achieves production efficiency. High, reducing the process of deburring, the effect of high quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

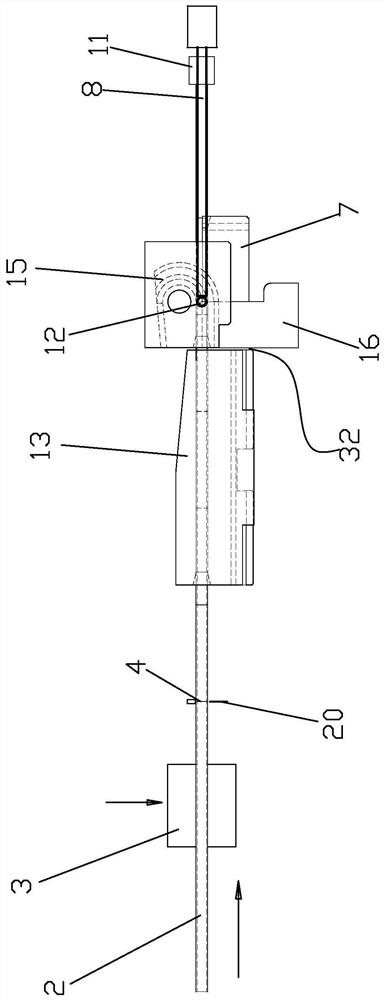

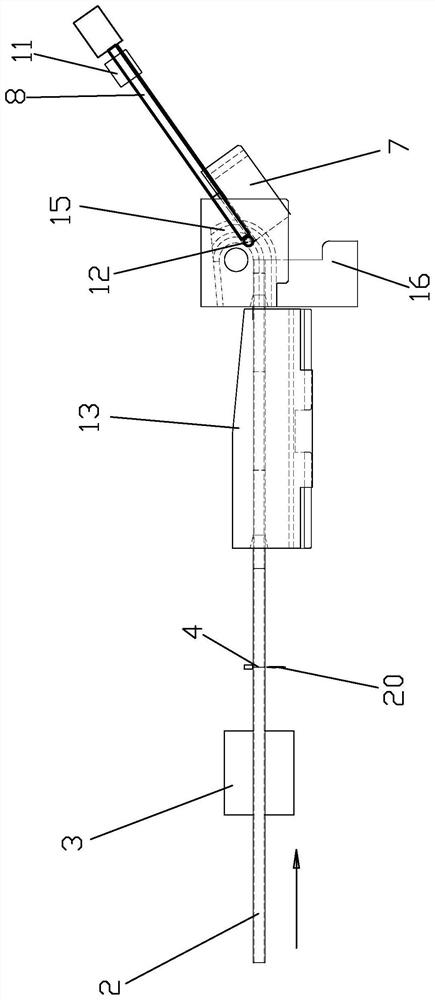

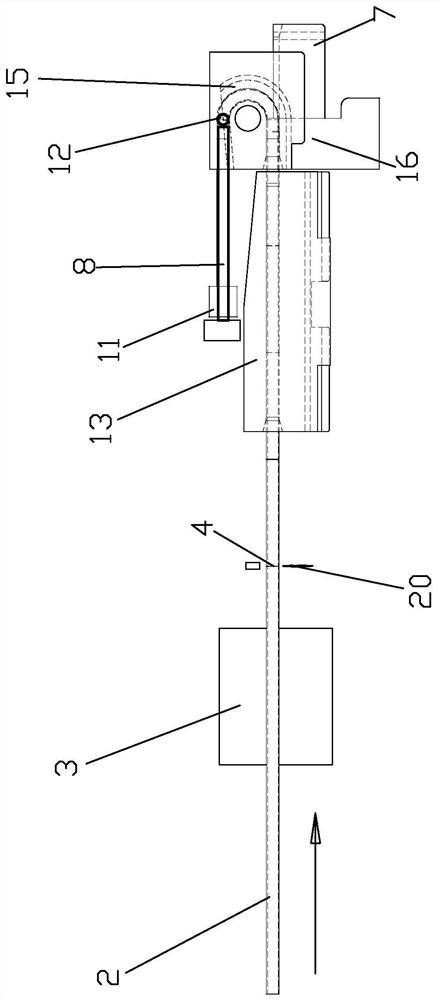

[0034] The technical features of the present invention will be described in further detail below in conjunction with the accompanying drawings so that those skilled in the art can understand.

[0035] A U-shaped tube chipless forming machine, such as Figure 1 to Figure 3 As shown, it includes a frame on which a feeding device, a clamping device for clamping the pipe fitting 2, a bending device, an anti-slope device for preventing the pipe fitting 2 from being inclined when it is bent, and Cutting mechanism. The pipe fittings 2 are generally copper pipes and multiple pipes are bent at the same time.

[0036] The feeding device includes a screw mandrel fixed on the frame, a feeding motor that drives the screw mandrel to rotate, a feeding transmission belt, a connecting nut that is sleeved on the screw mandrel and moves with the rotation of the screw mandrel, and is fixed on the connecting nut for The feeding clamp for clamping the pipe fitting 2 and the auxiliary feeding clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com