Shaping device for decorative picture frame production

A technology of picture frames and shaping molds, applied in metal processing, etc., can solve the problems of increased labor intensity, cumbersome cutting process, and affecting shaping efficiency, so as to reduce labor intensity and improve shaping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

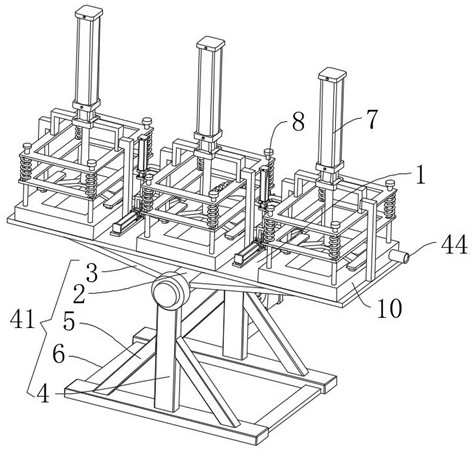

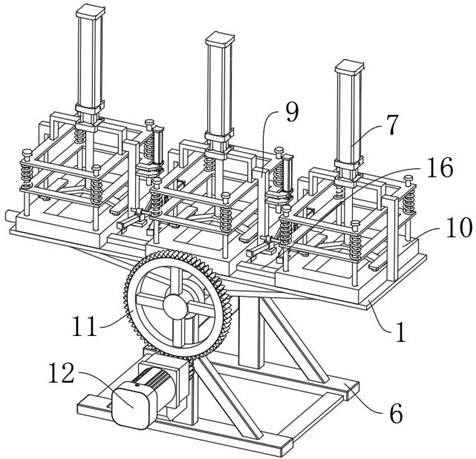

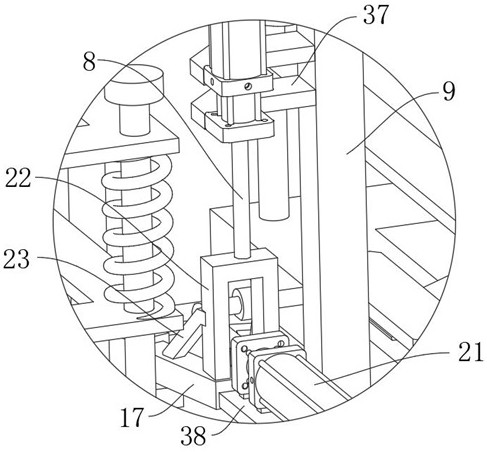

[0027] Such as Figure 1-Figure 9 A sizing device for the production of a decorative picture frame shown includes a mold base 1, a flipper 41 is installed on the lower end of the mold base 1, and multiple sets of shaping dies 10 are installed on the upper end of the die base 1. Between the multiple sets of shaping dies 10 There is a flow channel 16 between them, and a lifting piece 42 is installed on the top of the mold base 1. The lifting piece 42 is connected with the shaping mold 10, and a tangent piece 43 is installed between the two adjacent sets of shaping molds 10. The tangential piece 43 is connected to the lifting 42 are connected, wherein the side of a set of sizing dies 10 located at the edge is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com