Glass reinforced plastic sand inclusion jacking pipe with function of glass reinforced plastic connecting lantern ring

A technology of FRP sand inclusion and connecting ferrules, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problem that the long-term performance of steel ferrules is difficult to guarantee, the matching size error is too large, and it is difficult to ensure the impermeability. and other problems, to achieve the effect of simple structure, small connection and matching error, and long-term use performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

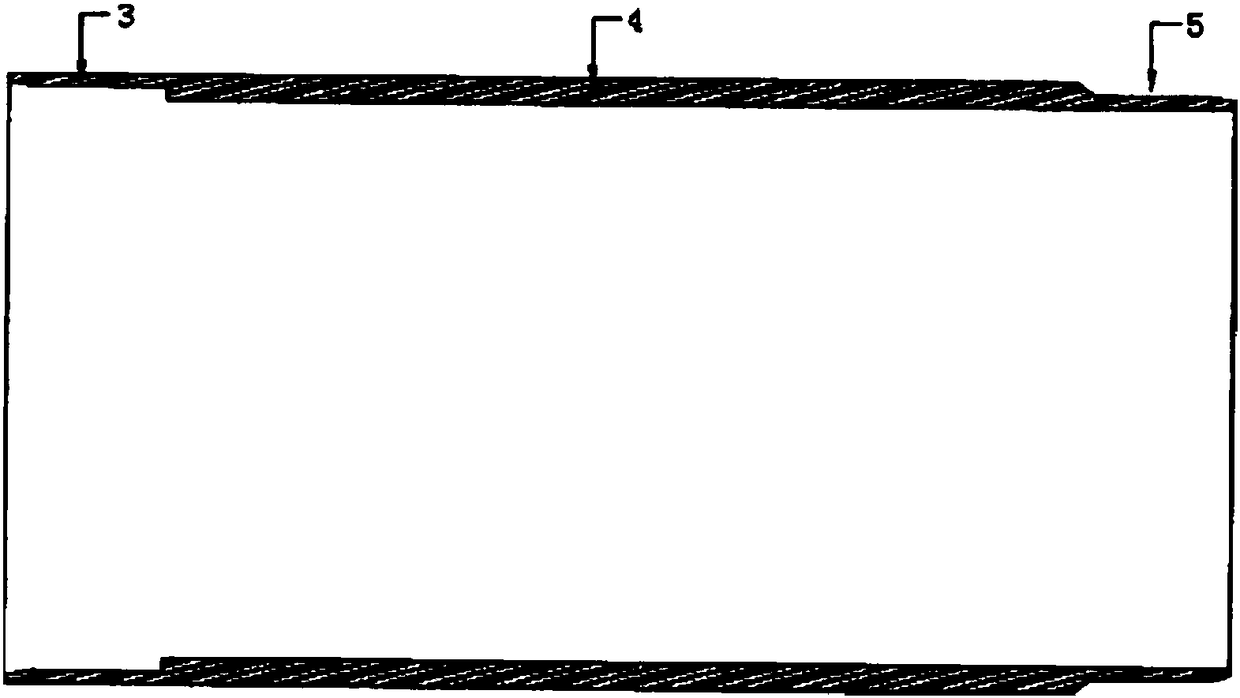

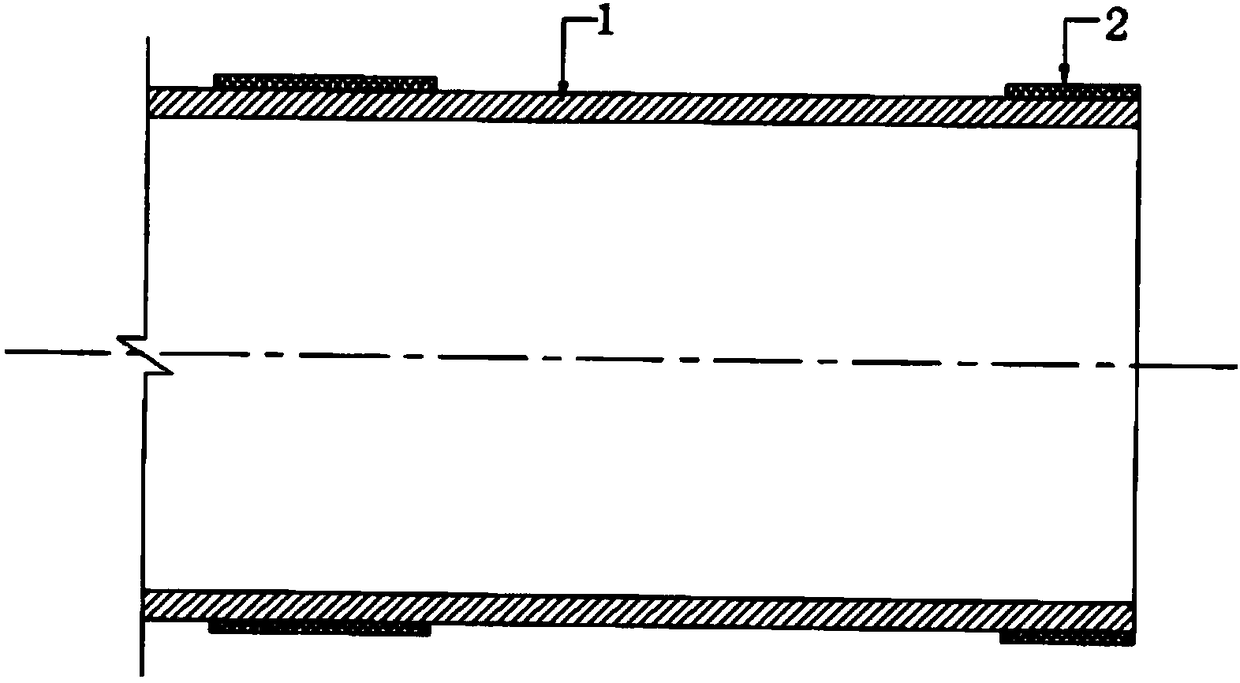

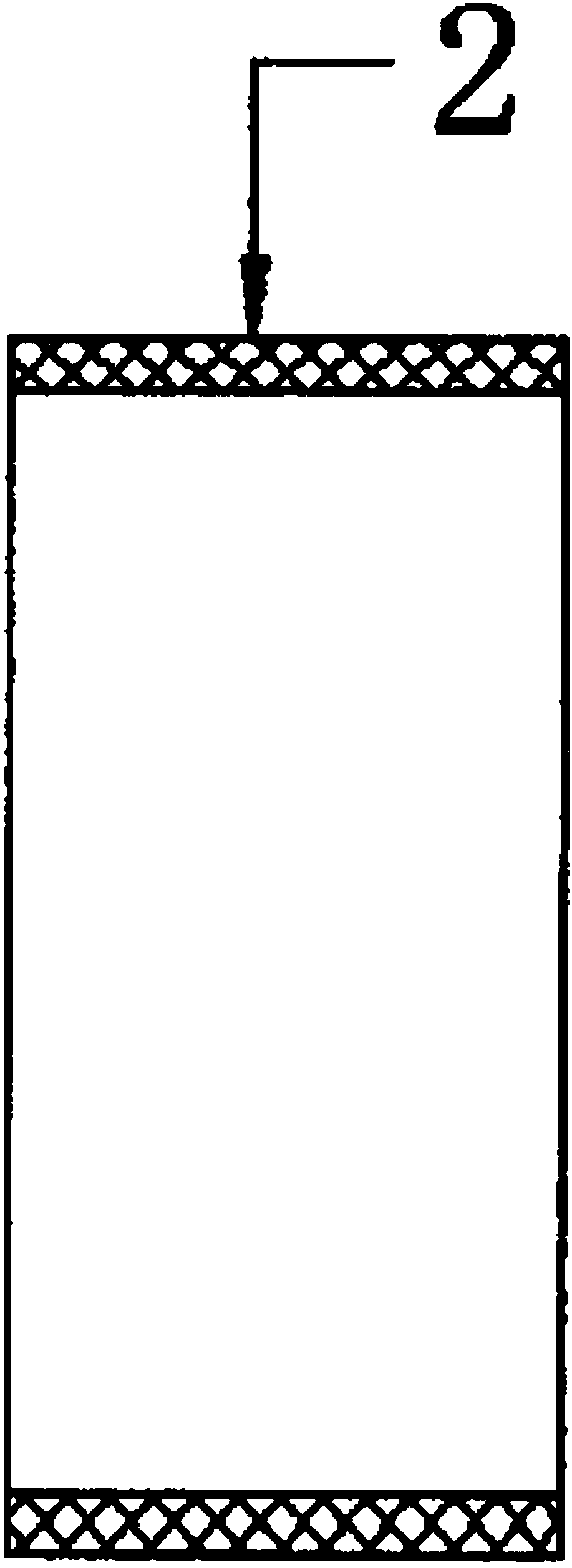

[0032] Such as figure 1 , Figure 7 As shown, a glass fiber reinforced plastic sand-jammed jacking pipe with a glass fiber reinforced plastic connecting ring function includes a pipe body 4, one end of the pipe body 4 is a socket end 5, the other end is a socket end 3, a pipe body 4, a socket end 5, and a socket The end 3 is an integral structure, and the outer diameter of the socket end 5 corresponds to the inner diameter of the socket end 3; the ports of the socket end 5 and the socket end 3 are respectively provided with guiding inclined surfaces.

[0033] One rubber groove 6 is opened on the socket end 5, and there is one sealing rubber ring, and the sealing rubber ring is located in the rubber groove 6.

example 2

[0035] Such as figure 1 , Figure 8 As shown, a glass fiber reinforced plastic sand-jammed jacking pipe with a glass fiber reinforced plastic connecting ring function includes a pipe body 4, one end of the pipe body 4 is a socket end 5, the other end is a socket end 3, a pipe body 4, a socket end 5, and a socket The end 3 is an integral structure, and the outer diameter of the socket end 5 corresponds to the inner diameter of the socket end 3; the ports of the socket end 5 and the socket end 3 are respectively provided with guiding inclined surfaces.

[0036] There is a rubber groove 6 on the socket end 5, one sealing rubber ring, and the sealing rubber ring is located in the rubber groove 6. The inner side of the rubber groove 6 (toward the socket end) of the socket end 5 is provided with a grouting reduction Resistance hole 7.

example 3

[0038] Such as figure 1 , Picture 9 As shown, a glass fiber reinforced plastic sand-jammed jacking pipe with a glass fiber reinforced plastic connecting ring function includes a pipe body 4, one end of the pipe body 4 is a socket end 5, the other end is a socket end 3, a pipe body 4, a socket end 5, and a socket The end 3 is an integral structure, and the outer diameter of the socket end 5 corresponds to the inner diameter of the socket end 3; the ports of the socket end 5 and the socket end 3 are respectively provided with guiding inclined surfaces.

[0039] Two rubber grooves 6 are opened on the socket end 5, and there are two sealing rubber rings, and the sealing rubber rings are located in the rubber groove 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com